REPAIR INSTRUCTIONS, PART 2

Page 385

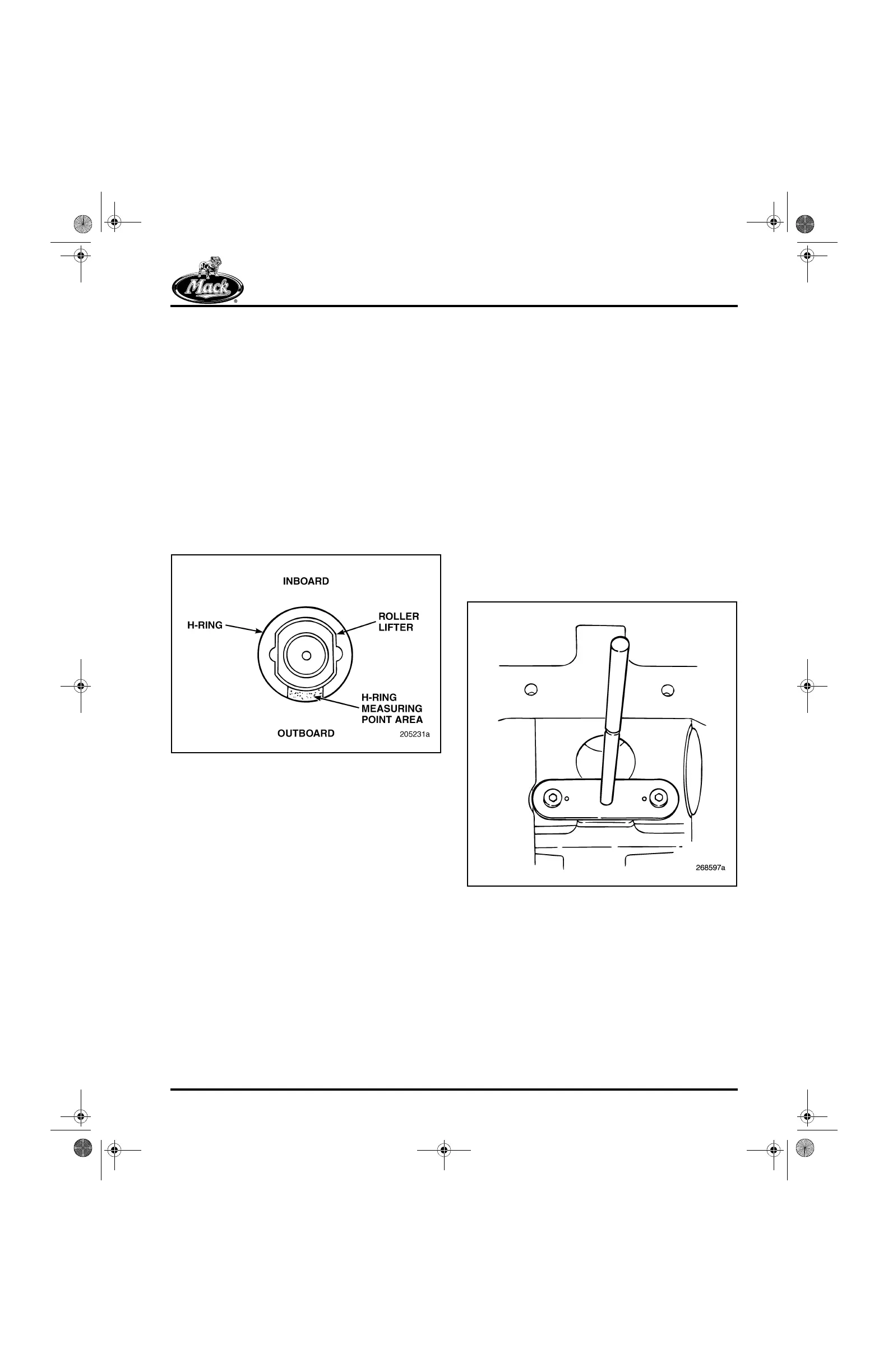

H-Ring Dislodgement Inspection

Dislodging of the H-ring from its bore results from

valve lifter inertia forcing the H-ring upward.

When the H-ring at a failure cylinder is higher

than that of an adjacent cylinder, the appropriate

action must be taken depending upon how much

the H-ring has been pushed upward. Measure the

installation depth of the H-ring as follows:

1. If not previously done, remove the push rod

and look down the push rod hole, observing

the top of the lifter and the top of the H-ring.

2. Place a length of welding rod (approximately

15 inches long) on top of the H-ring, at the

outboard side. Refer to Figure 457.

457

Figure 457 — H-Ring Measuring Point

3. Place a straightedge on the cylinder head

top rail surface, in contact with the welding

rod.

4. Mark the welding rod at the point where it

contacts the straightedge.

5. Perform the same check at an adjacent

cylinder and mark its point of contact on the

welding rod. Compare the measurement

taken at the adjacent cylinder with the

measurement taken at the suspect failure

cylinder.

앫 If the H-ring at the failure cylinder is the

same height-to-1/16 inch (0–1.587 mm)

higher as compared to that of an

adjacent OK cylinder, it is concluded

that no partial dislodging of the H-ring

has occurred. No further action is

required.

앫 If the H-ring at the failure cylinder is

1/16–1/8 inch (1.587–3.175 mm) higher

than that of an adjacent OK cylinder,

the H-ring position is OK.

앫 If the H-ring is more than 1/8 inch

(3.175 mm) higher than that of an

adjacent OK cylinder, the H-ring has

become dislodged and must be

replaced.

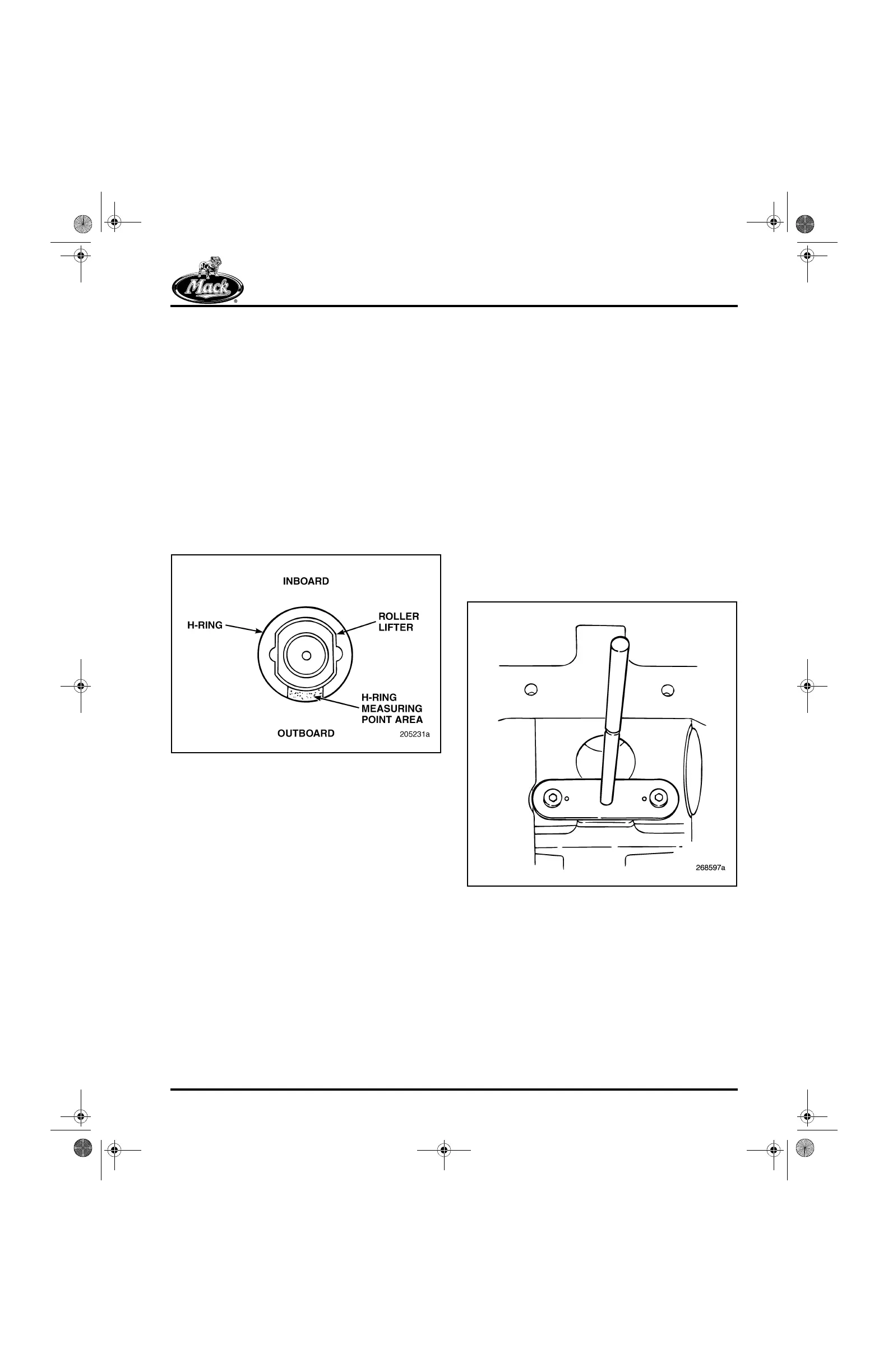

H-Ring Alignment Inspection

H-ring alignment is checked with H-ring alignment

checking tool No. J 46083 as follows:

1. With the camshaft and lifters removed, insert

the alignment checking tool J 46083 into the

mating pair of lifter bores from the crankcase

side.

458

Figure 458 — Alignment Tool Inserted into Lifter Bore

2. Check to see if the depth groove on the tool

handle aligns with the oil pan mounting

surface of the cylinder block. If both H-rings

are in alignment, the tool will be inserted all

the way into the lifter bores, and the depth

groove on the handle will align with the oil

pan mounting surface. If either of the H-rings

is not in alignment, the tool will not fully

insert into the lifter bores and the insertion

depth groove on the tool handle will not align

with the oil pan mounting surface.

5-111.bk Page 385 Monday, July 10, 2006 2:26 PM

Loading...

Loading...