Page 254

REPAIR INSTRUCTIONS, PART 1

Inlet and Exhaust Valve Installation

For identification purposes, the exhaust valve has

two stem grooves in addition to the valve spring

keeper groove; whereas, the inlet valve has one

stem groove in addition to the spring keeper

groove.

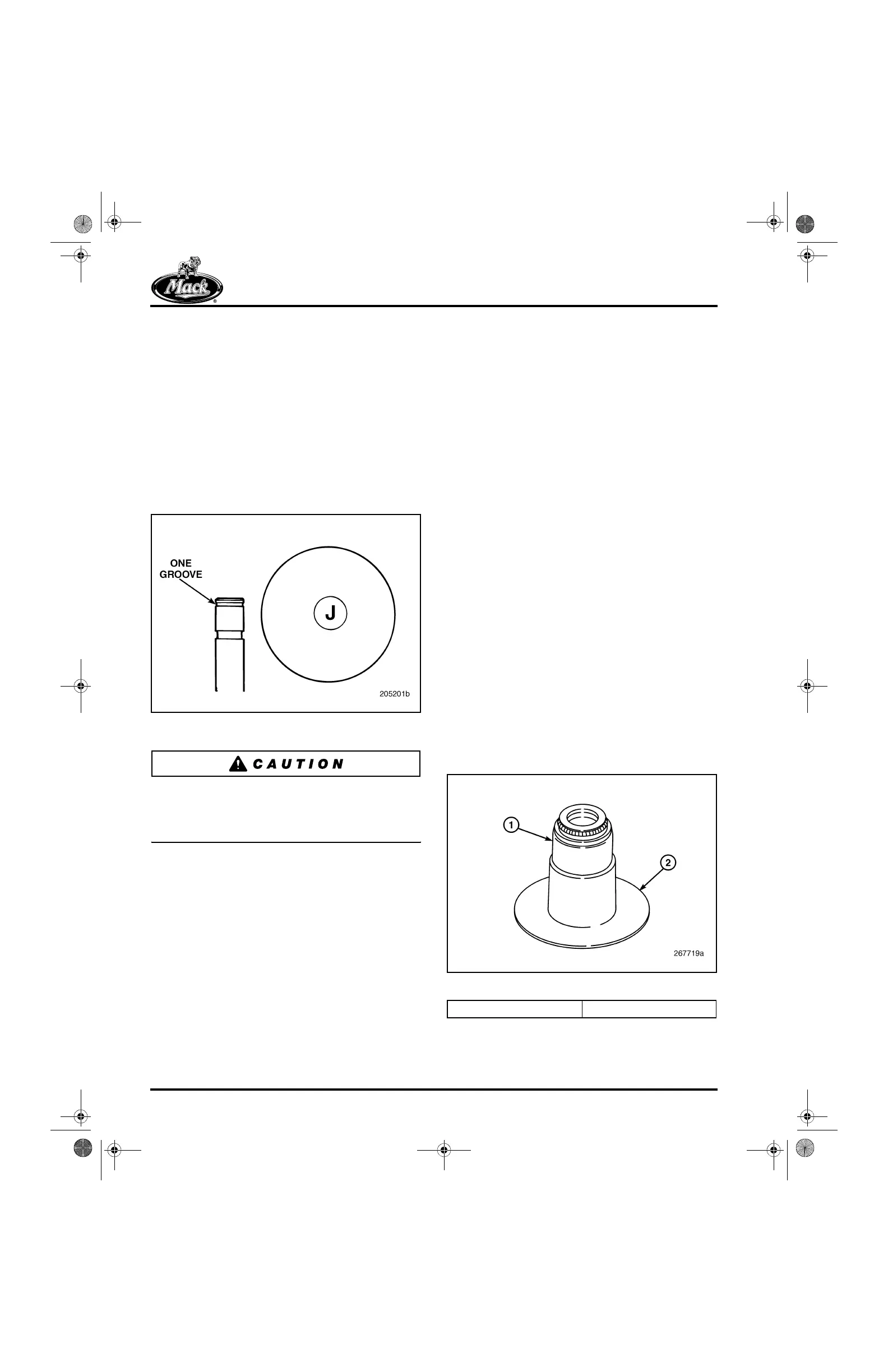

The valves are also identified by the letter “J”

(20-degree inlet), and letters “EX” (exhaust), on

the bottom face of the valve head. Refer to

Figure 278 for an illustration of the inlet valve

identification.

278

Figure 278 — 20-Degree Intake Valve Identification

The inlet and exhaust valve head diameters are

nearly the same size. It is important, therefore,

that extra care be taken when installing these

valves.

1. Lubricate the inside diameter of the valve

guides by using a “bottle brush” coated with

Dow Corning

®

BR2 Plus multipurpose

grease. This is particularly important when

both the valves and the valve guides are

new. (With an on-engine seal replacement,

pre-lube the valve stems with clean engine

oil while moving the valve up and down,

prior to installation of the valve spring.)

2. With these new valve stem seals,

pre-lubrication during installation is

extremely important. Pre-lubricate the seals

as follows:

앫 Valve Stem-to-Guide — Lubricate the

inside diameter of the valve guides by

using a “bottle brush” coated with

graphite grease. This is particularly

important when both the valves and the

guides are new. With an on-engine seal

replacement, pre-lubricate the valve

stems with clean engine oil while

moving the valve up and down before

installing the valve spring(s).

앫 Valve Stem-to-Seal Lip — The inside

diameter of the seal lip and outside

diameter of the valve stem should be

well-lubricated with clean engine oil

when installing the seal over the valve

stem.

3. Early Design Valve Guide and Stem Seal

A combination valve spring seat and integral

stem seal was used on the first 200 ASET™

engines. This early design seal is no longer

available. Engines built with this seal

arrangement will need to be converted to the

current configuration multi-lip type seal. This

conversion will require the replacement of

the valve guides to the current configuration.

Refer to “Valve Guide Replacement” earlier

in this section.

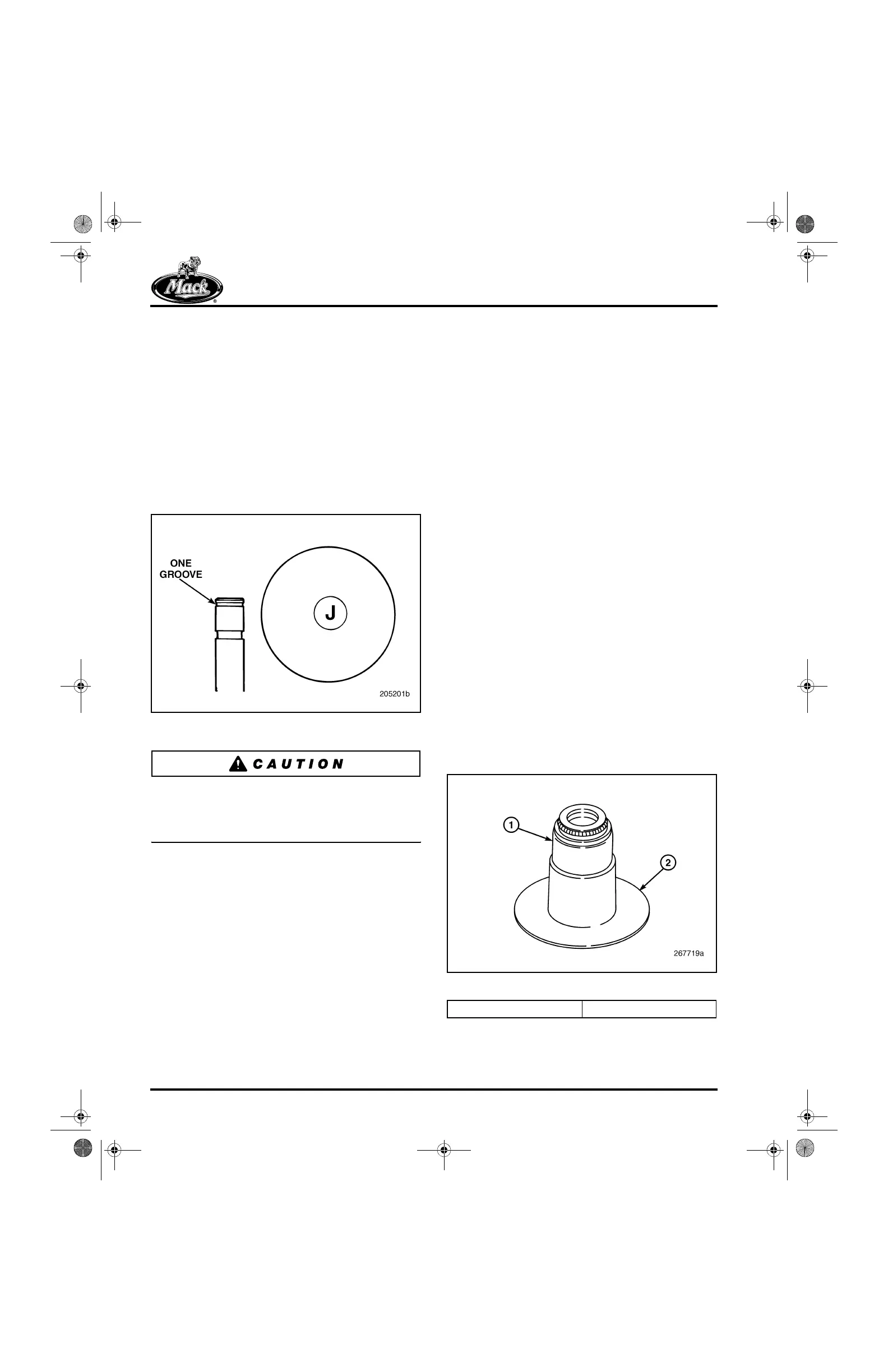

279

Figure 279 — Valve Stem Seal (Early Design)

1. Valve Stem-to-Seal Lip 2. Valve Stem Seal

5-111.bk Page 254 Monday, July 10, 2006 2:26 PM

Loading...

Loading...