DESCRIPTION AND OPERATION

Page 53

With the J-Tech™ engine brake, the standard

ASET™ engine valve yokes are used at both inlet

and exhaust locations. However, a hollow yoke

adjusting screw with a floating pin in the screw is

used in the exhaust yokes (Figure 53). The screw

opens only the exhaust valve directly beneath it

when the engine brake is activated. In addition,

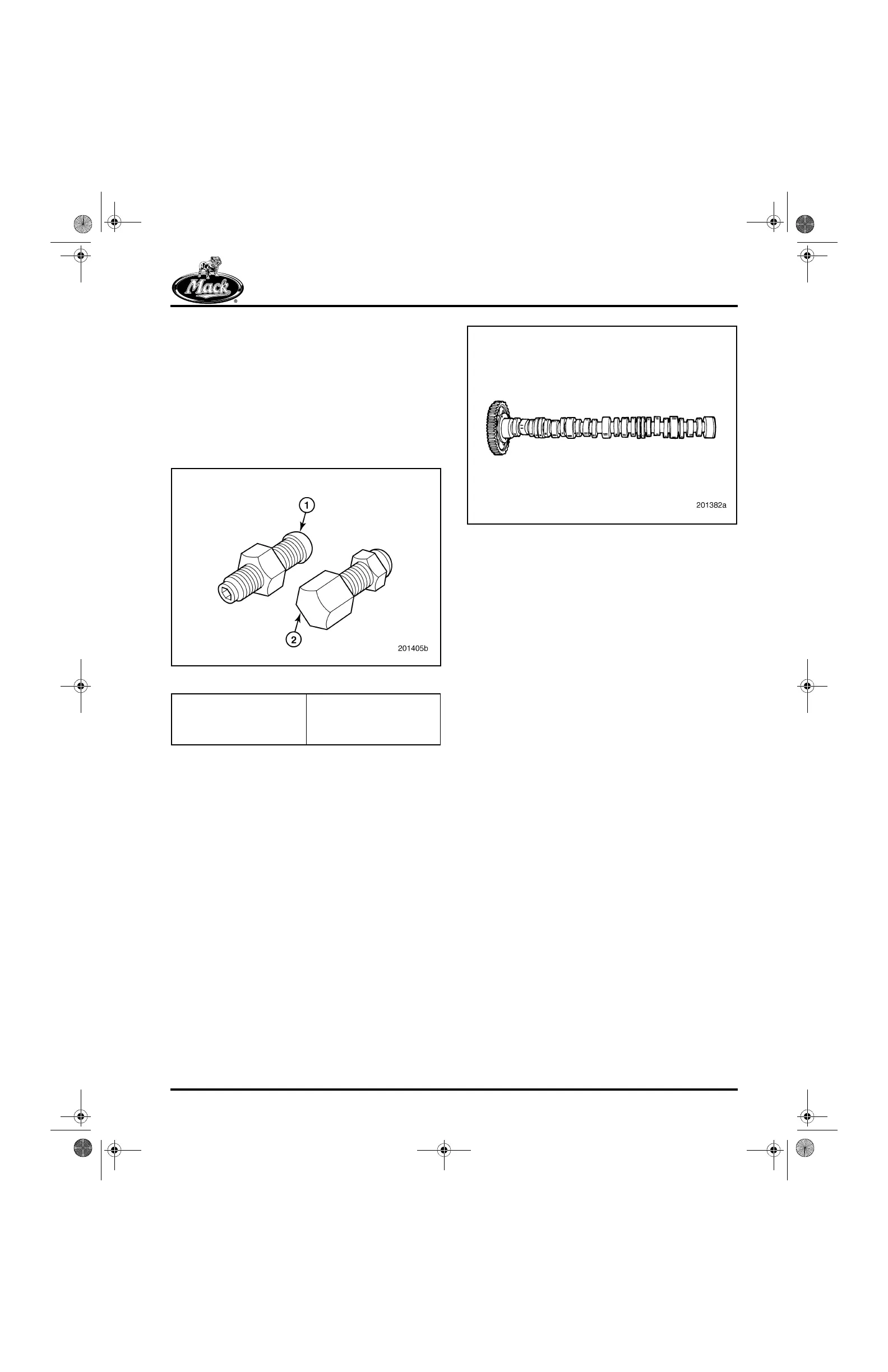

the exhaust rocker arm adjusting screws and nuts

(Figure 55) are unique for the J-Tech™ engine

brake application.

55

Figure 55 — Rocker Arm Adjusting Screws and Nuts

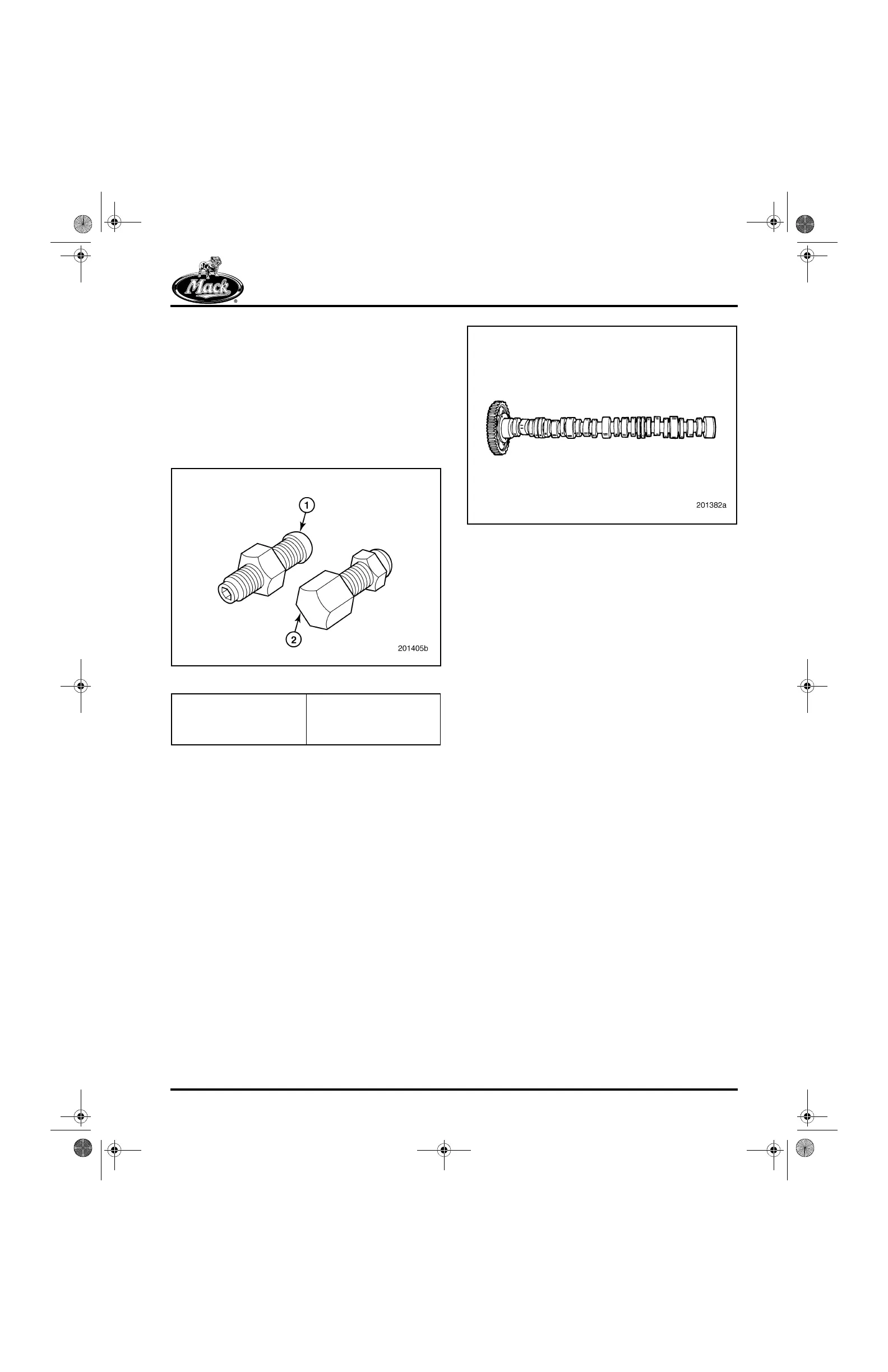

Camshaft

The camshaft (Figure 56) is machined with lobes

for actuating the unit pumps and the inlet and

exhaust valves. The large diameter of the

camshaft provides the additional strength needed

for operating the unit pumps as well as the valve

train. Journals and lobes are induction-hardened

by a process that produces a pronounced heat

discoloration mark approximately 3/8-inch wide,

around the front and rear faces of each journal

and lobe.

Other notable features of the camshaft include a

bump in the exhaust cam profile that provides

timing for engine brake operation. There is also a

groove in the No. 4 journal to aid in reducing cam

bushing temperature.

56

Figure 56 — Camshaft

Valve Train

ROLLER LIFTERS/FOLLOWERS

Roller lifters and roller followers or “tappets” are

used to actuate the valves and unit pumps,

respectively. The roller aspect of these

assemblies handles aggressive cam profiles

better and has increased load-carrying capability.

The roller lifters are held in alignment by H-rings

pressed into the lifter bores; whereas, the EUP

roller followers are held in alignment by the tappet

guide pins pressed into the cylinder block.

The current redesigned roller lifter has two longer

lands that provide more bearing area than the

previous design, and the lifter body is now made

of hardened steel for greater scuff resistance

(Figure 57). The bronze axle used in the previous

design has been replaced with a steel axle having

a smaller diameter for optimization of roller and

axle sizes. The pressure oil feed hole to the axle

has been eliminated and replaced with oil

grooves on the inside of the lifter legs. The lifter

roller is composed of a ceramic material

specifically designed for use in engine

components.

When handling ceramic roller lifter assemblies,

care must be taken to avoid damage. If a lifter

having a ceramic roller is dropped, cracks that

are too small to detect may be present and result

in failure of the ceramic roller. DO NOT use a

ceramic roller lifter that has been dropped.

1. Standard Rocker Arm

Adjustment Screw and

Nut

2. Special Screw and

Spherical Jam Nut

(J-Tech™ Exhaust

Position Only)

5-111.bk Page 53 Monday, July 10, 2006 2:26 PM

Loading...

Loading...