Page 54

DESCRIPTION AND OPERATION

57

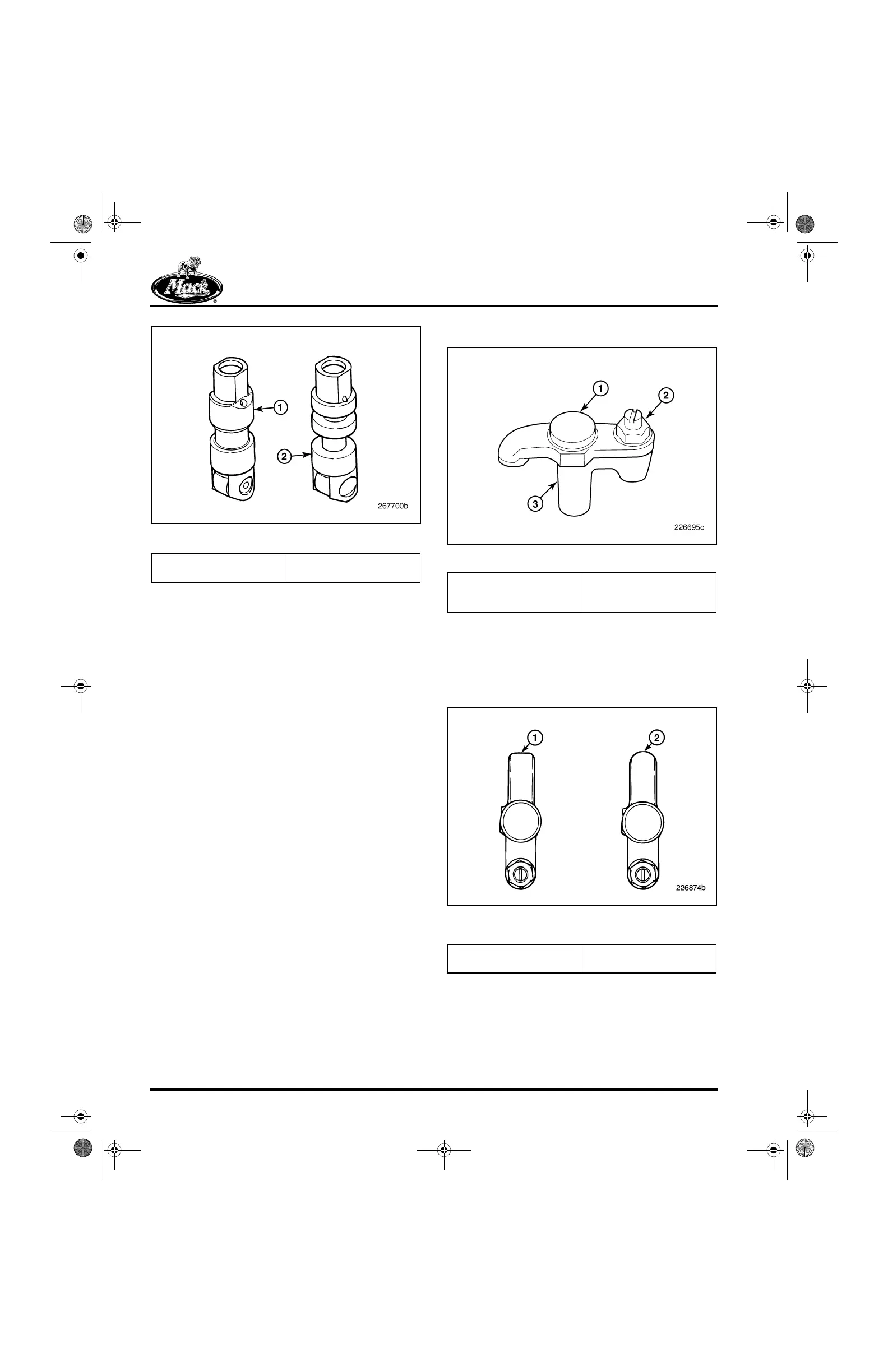

Figure 57 — Roller Lifters

VALVES

The stem tip of the valve has grooves to identify

the valve as intake or exhaust. The intake valve

has one stem groove in addition to the valve

spring keeper groove; the exhaust valve has two.

Seat face angles are also different, 20 degrees

for the intake and 30 degrees for the exhaust.

YOKES

Pinless valve yokes are used for the inlet valves

(with standard push rods), and non-brake

exhaust valves (with spring-loaded push rods).

The spring-loaded push rods have made it

possible to use pinless valve yokes at the

exhaust locations on non-brake engines. As a

result, valve yoke guide pins at the inlet and

non-brake exhaust valve locations have been

eliminated from the cylinder heads.

AC engines equipped with an engine brake have

pin-type yokes at the exhaust valve locations and

pinless yokes at the inlet valve locations. Both are

made of ductile iron and have a button-style wear

pin at the point of rocker arm engagement.

Significant dimensional changes and

modifications have occurred in valve yoke design

over the years. As a result, it is important that the

correct valve yokes are used in all service work.

The following will help in identifying the correct

parts to use.

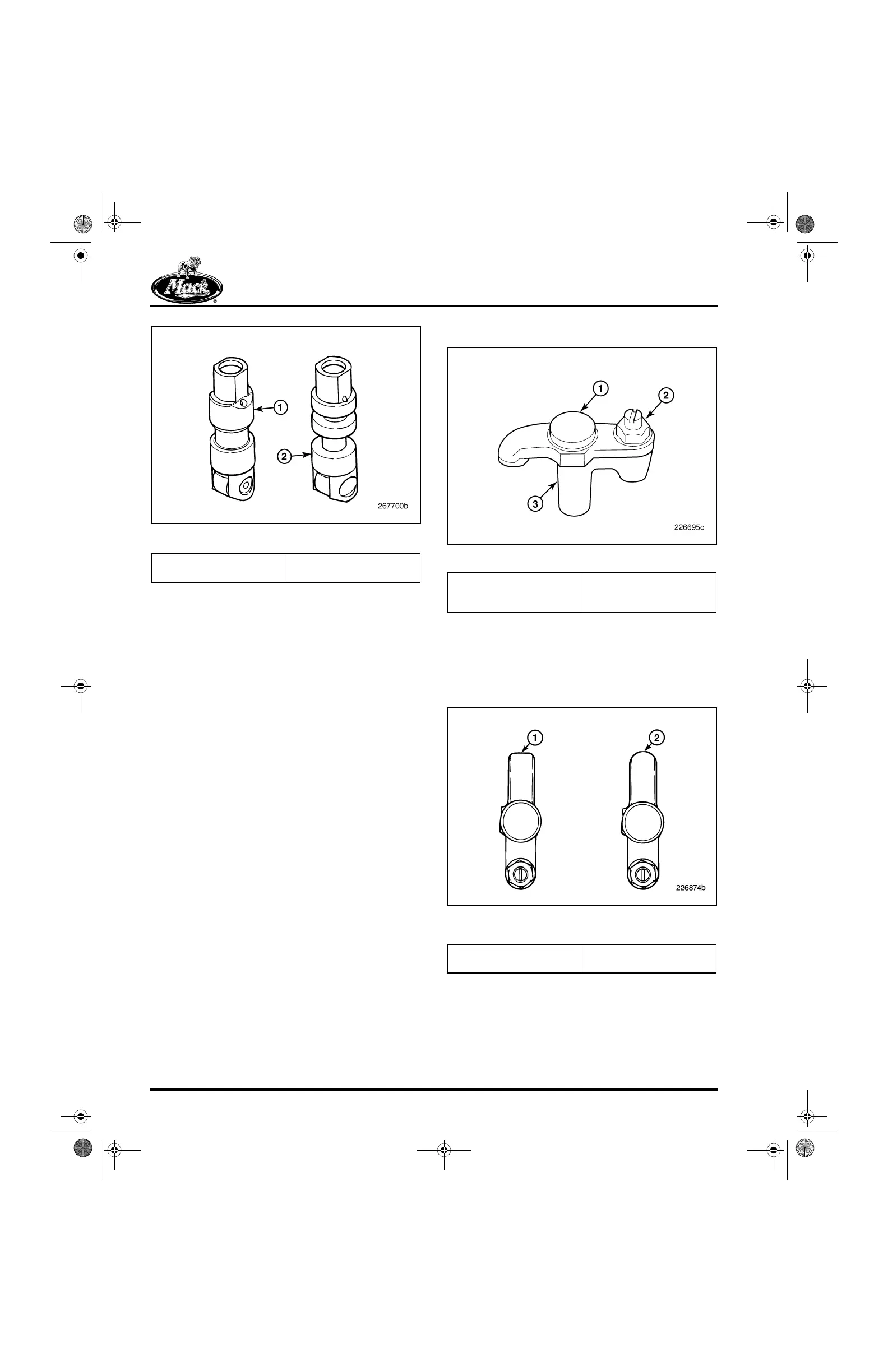

Pin-Type Yoke

58

Figure 58 — Current Valve Yoke

The most positive method of identification is to

look at the nose of the valve yoke.

ASET™/E-Tech™ valve yokes have the nose

end of the slipper pad area ground flat as shown

in Figure 59.

59

Figure 59 — ASET™/E-Tech™ and E7 Valve Yokes (Top

View)

1. Current Ceramic Roller

Lifter

2. Non-Current Steel Roller

Lifter

1. Headed Pin

2. Adjusting Screw and Jam

Nut

3. Valve Yoke

1. Flat Ground Nose

(ASET™/E-Tech™)

2. Rounded Nose (E7 Only)

5-111.bk Page 54 Monday, July 10, 2006 2:26 PM

Loading...

Loading...