DESCRIPTION AND OPERATION

Page 55

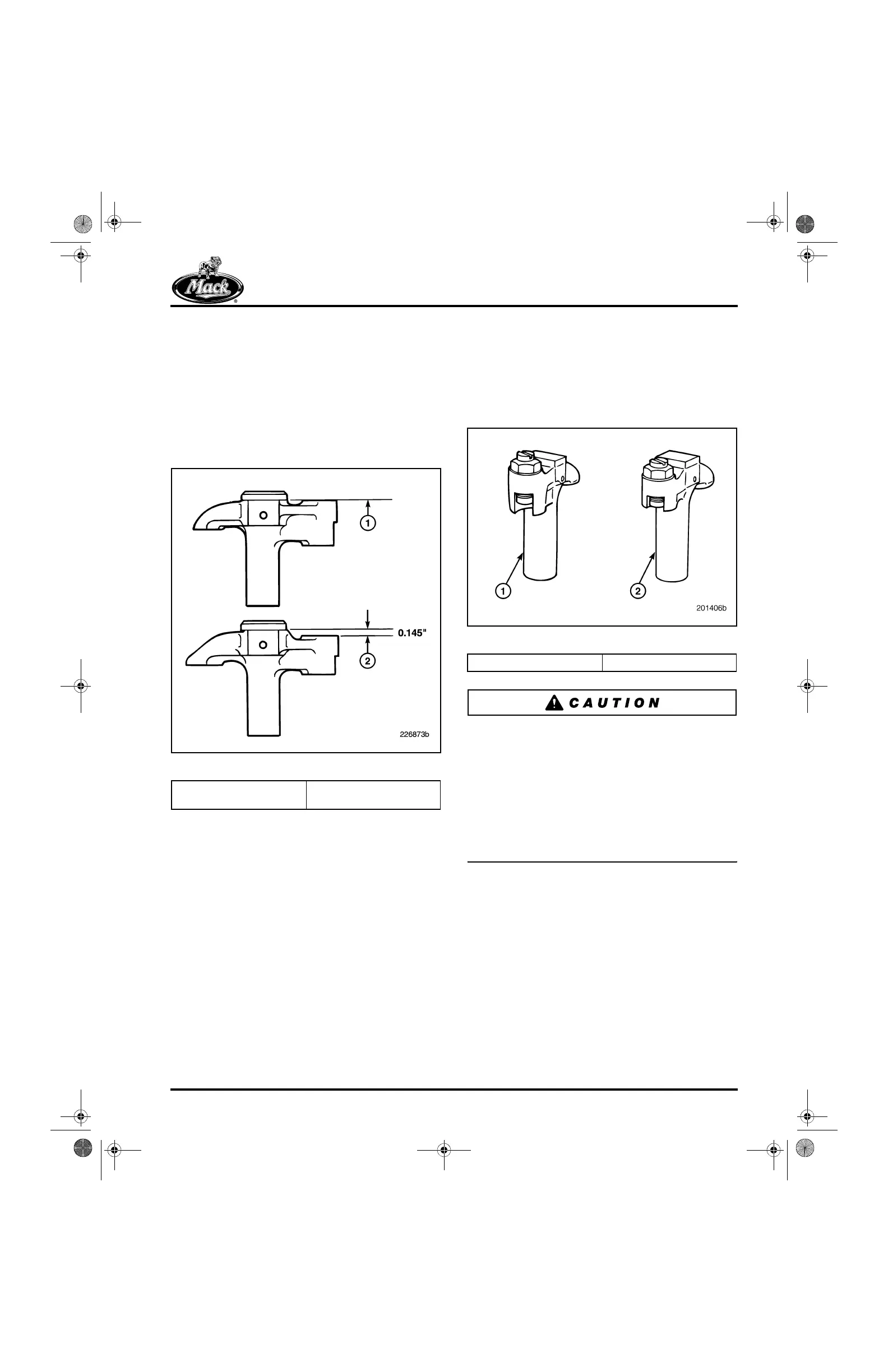

A second method of identifying the “button-head”

yoke is to look at the side view. On the yoke

design used for the ASET™ engines, the top

surface of the adjusting screw end is on the same

plane as the bottom surface of the “button-head.”

On valve yokes used on engine models prior to

ASET™ and E-Tech™, the top surface of the

adjusting screw area is 0.145 inch below the

bottom surface of the “button-head.” Refer to

Figure 60 for an illustration of these differences.

60

Figure 60 — Valve Yoke Side View

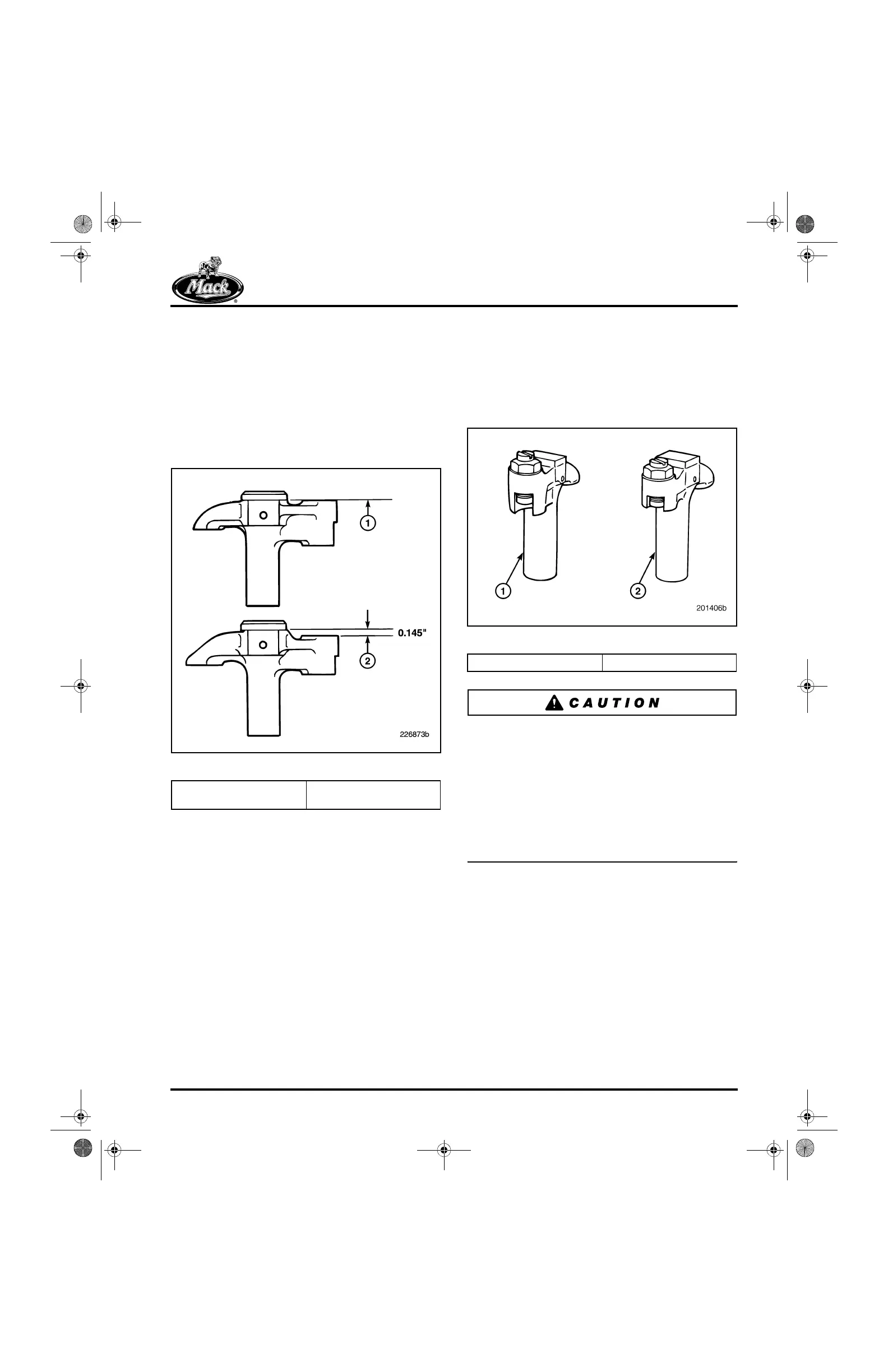

The valve yokes used on the ASET™/E-Tech™

engines have a deeper engagement at the yoke

screw end than the yokes used on the E7-PLN

engine, because of the longer valve (Figure 61).

ASET™/E-Tech™ and E7-PLN yokes are very

similar in appearance, but should not be

interchanged.

61

Figure 61 — Valve Yokes

DO NOT interchange yokes. For example, if a

current design yoke from an ASET™ engine is

used on an earlier E7 engine, the valve keepers

will become dislodged and cause a dropped

valve. This will cause severe engine damage. If

the non-current design yoke from an E7 engine is

used on an exhaust location of a J-Tech™

brake-equipped ASET™ engine, the yoke will

disengage from the valve stem tip during engine

brake operation. See Figure 62.

1. Same Plane

(ASET™/E-Tech™)

2. Below (0.145″ for E6, E7

and E9 Only)

1. Current 2. Non-Current

5-111.bk Page 55 Monday, July 10, 2006 2:26 PM

Loading...

Loading...