REPAIR INSTRUCTIONS, PART 1

Page 235

INSPECTION

Pressure Test — It is recommended that cylinder

heads be pressurized and checked for internal

cracks and leaks. Refer to the “Cylinder Head

and Cylinder Block Leak Test” procedure in the

TROUBLESHOOTING section.

Check the cylinder head deck surface for

warping, pitting or other imperfections. Deck

surface flatness must not vary more than

0.0015 inch (0.0381 mm) over 18 inches

(45.7 cm) of surface area. Resurface or replace

as necessary.

When resurfacing, remove a minimum amount of

material from the deck to obtain a flat, uniform

surface. Standard head height is

6.397–6.391 inches (162.483–162.310 mm). A

maximum of 0.010 inch (0.254 mm) of material

may be removed, making the minimum height of

a resurfaced head 6.381 inches (162.077 mm).

When the deck is resurfaced, the fire ring groove

and valve seat insert dimensions must be

reestablished following the procedure under “Fire

Ring Groove Cutting.”

Fire Ring Groove Cutting

GENERAL INFORMATION

Fire ring grooves are located in the machined flat

surface (deck) of the cylinder head that mates

with the engine block. This design provides a

locking groove for the fire ring to seat, as well as

a positive-combustion pressure seal.

After resurfacing the cylinder head deck, it is

necessary to reestablish the fire ring groove

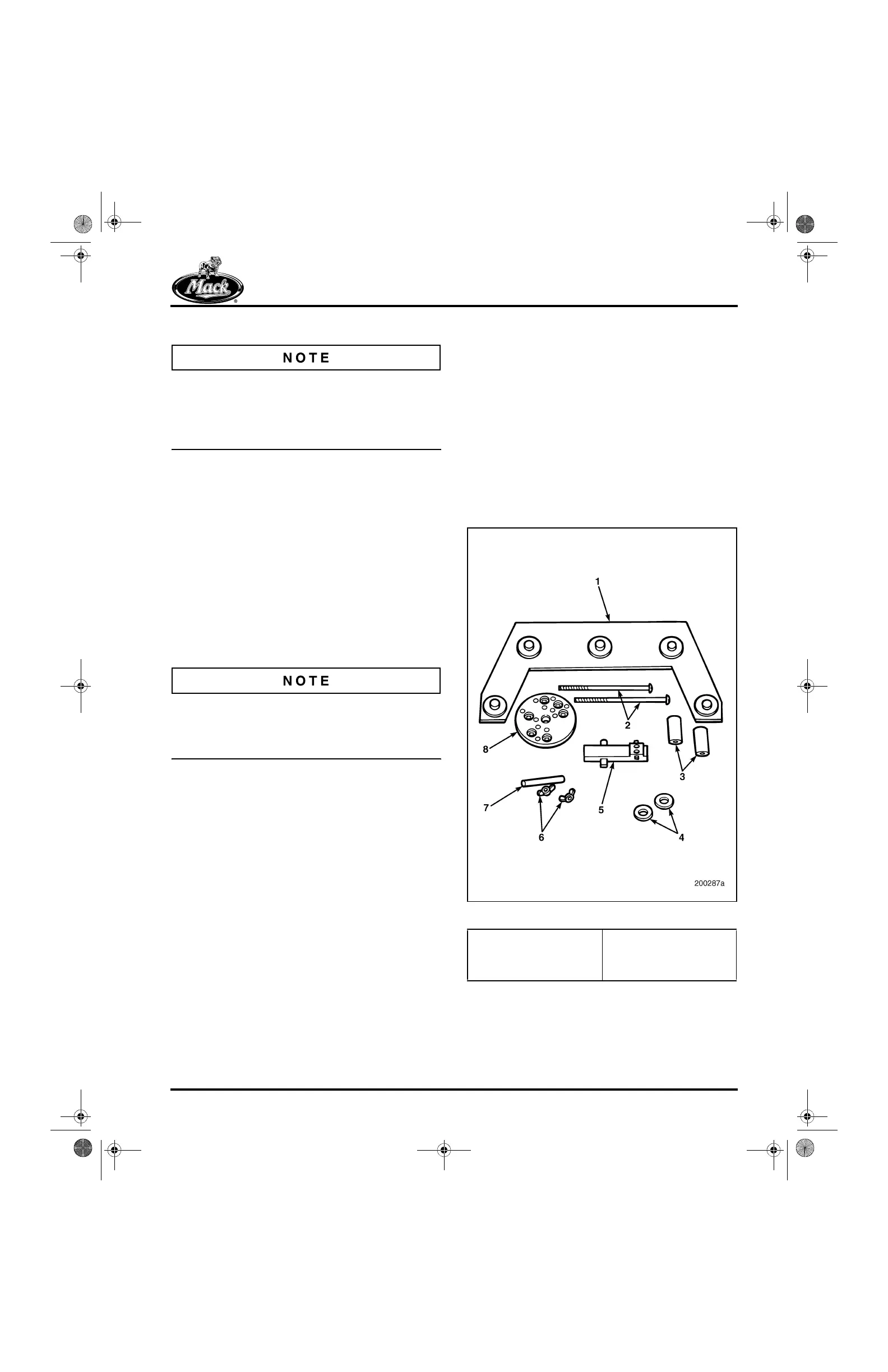

depth using the fire ring groove cutter J 29600-C

(Figure 249).

249

Figure 249 — Fire Ring Groove Cutter J 29600-C

1. Alignment Fixture

2. Hold-Down Capscrews

3. Spacers

4. Washers

5. Cutter Head (J 37719)

6. Wing Nuts

7. Thickness Gauges

8. Cutter Base

5-111.bk Page 235 Monday, July 10, 2006 2:26 PM

Loading...

Loading...