DESCRIPTION AND OPERATION

Page 43

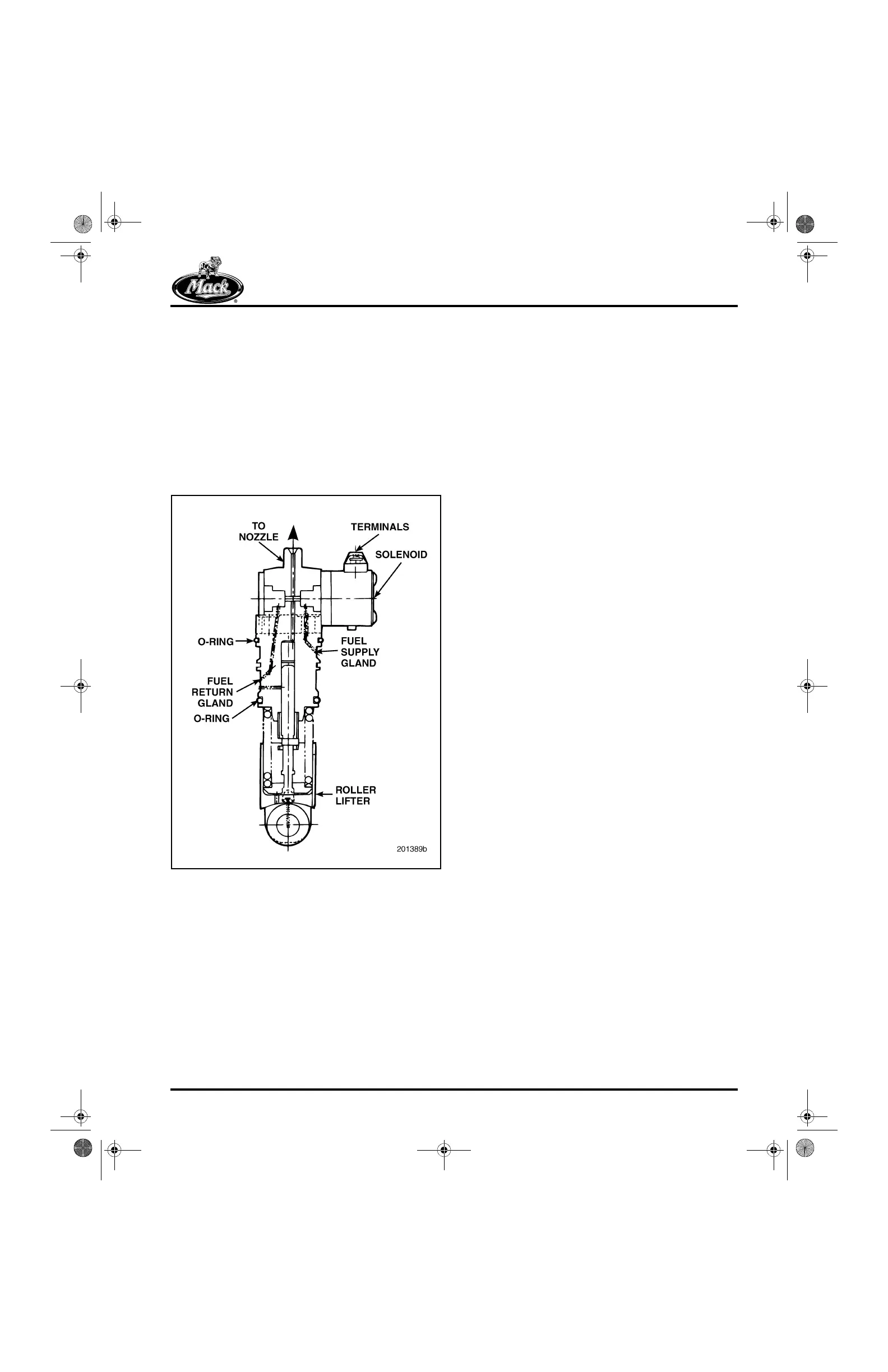

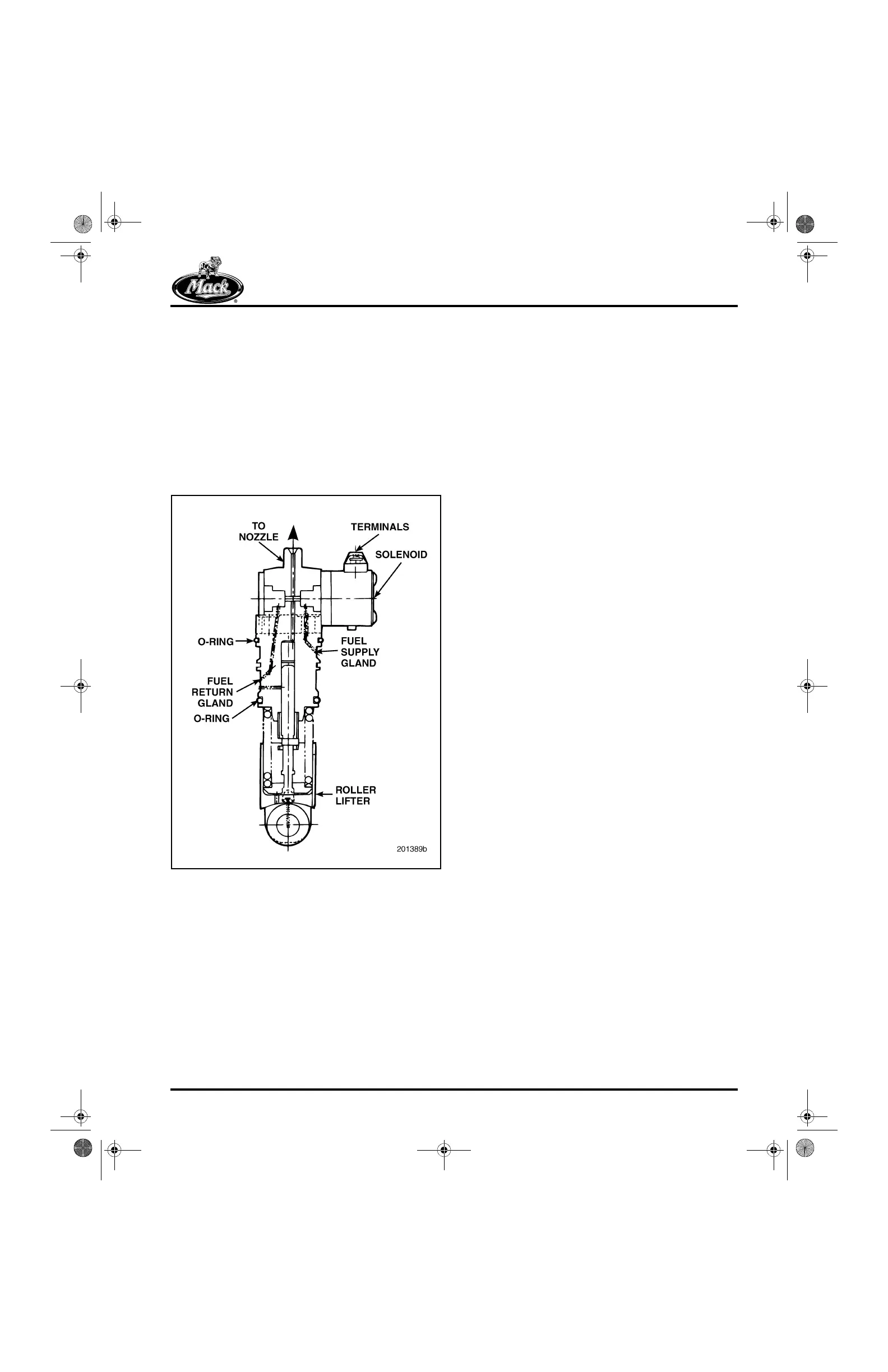

The EUP design does not include a helix on the

pump plunger. Fuel delivery is controlled entirely

by the solenoid valve. To start fuel delivery, the

V-MAC III control system allows current to flow to

the solenoid, closing the solenoid valve and

trapping fuel in the pump. As the plunger moves

upward, fuel is delivered through the

high-pressure line to the fuel-injector nozzle

assembly. When current flow to the solenoid is

stopped, the solenoid valve opens and fuel in the

pump then flows to the cylinder block fuel return

gallery. Refer to Figure 40.

40

Figure 40 — Electronic Unit Pump

The EUP system, using proven industry

technology, is well adapted to troubleshooting.

When required, an individual EUP can be

replaced with a minimum of downtime.

Because the unit pumps are located in close

proximity to the exhaust manifold, heat shields

(Figure 15) have been added to prevent

excessive heat from reaching the EUP

components. If removed during any maintenance

or repair operations, the heat shields must be

replaced to avoid damage to the sensitive

electronic components.

Engine Brake

The optional MACK PowerLeash™ and J-Tech™

engine brakes are vehicle-slowing devices that

allow the engine to act as an air compressor,

producing retarding horsepower that helps slow

the vehicle. The engine braking action is

accomplished through hydraulics. When the

engine brake is operated, a single exhaust valve

opens near top dead center of the compression

stroke, releasing high-pressure air out the

exhaust. Opening one exhaust valve, instead of

two, significantly reduces load to the engine

brake and the valve train without adversely

affecting braking power. Releasing compressed

air to the exhaust prevents the return of energy to

the engine piston on the expansion stroke. The

result is a net power loss from the engine, or

retarding horsepower, used to slow the vehicle.

MACK POWERLEASH™ ENGINE BRAKE

FEATURES AND OPERATION

The MACK PowerLeash™ engine brake has the

hydraulically controlled valve train components

integrated into the exhaust rocker arms. During

engine brake operation, one of the exhaust

valves in each cylinder is opened just as the

pistons approach top dead center of the

compression stroke, allowing the compressed

charge in each cylinder to be released and

vented to the engine’s exhaust system. The

energy of compression is then lost. This loss of

energy is what increases the braking effect of the

engine and allows the vehicle to slow down while

minimizing the need to use the service brakes to

slow the vehicle. The service brakes must always

be used to control the vehicle and bring the

vehicle to a complete stop.

5-111.bk Page 43 Monday, July 10, 2006 2:26 PM

Loading...

Loading...