REPAIR INSTRUCTIONS, PART 1

Page 223

CONNECTING ROD AND

PISTON BENCH PROCEDURES

Connecting Rod Inspection and

Reconditioning

[212 LP]

GENERAL INSTRUCTIONS

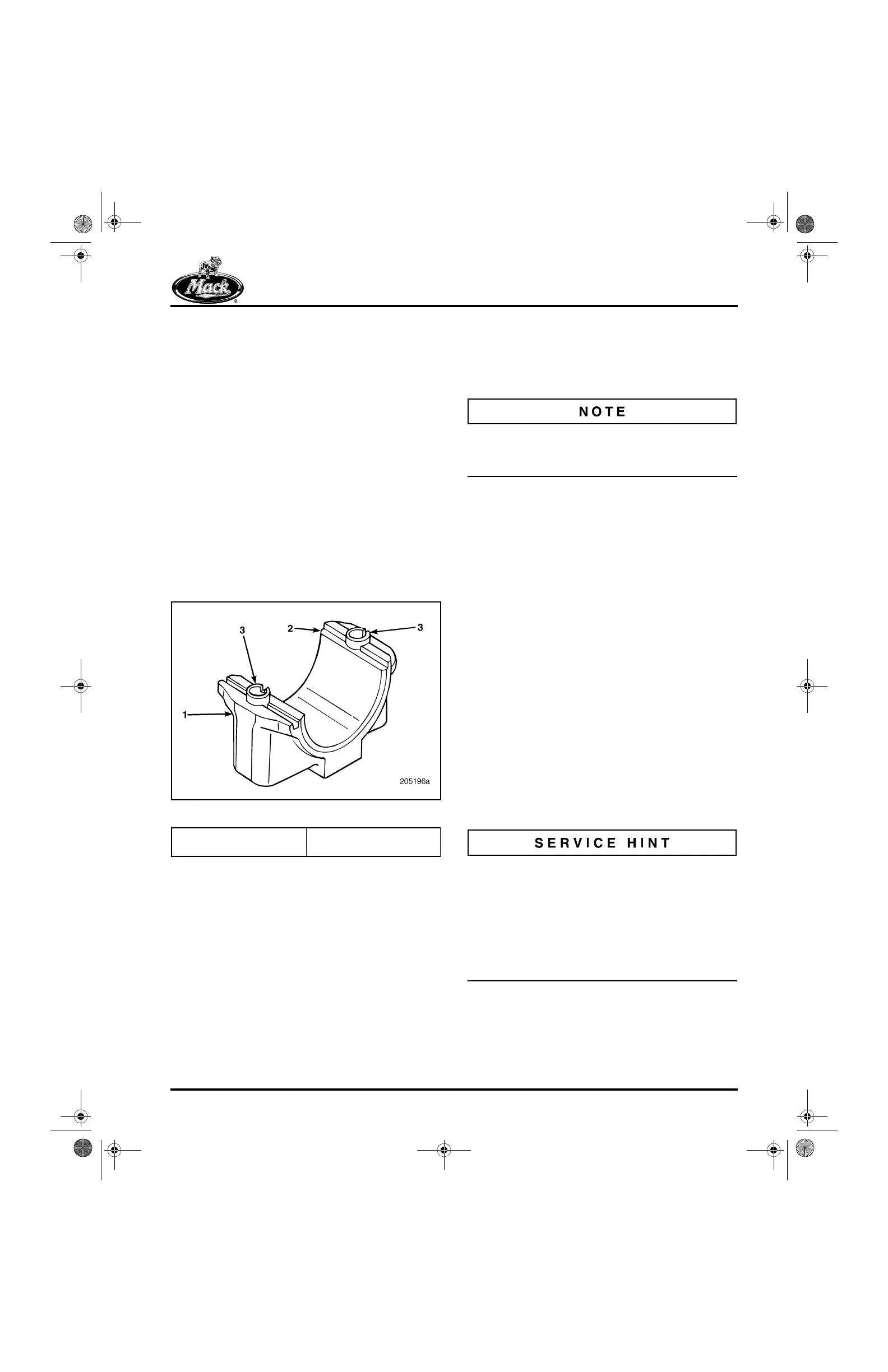

Each connecting rod assembly has two alignment

sleeves, one sleeve in each capscrew hole of the

rod cap to locate and align the cap and rod thrust

faces (Figure 230). These sleeves provide the

best alignment when the sleeve gaps are

positioned at a location approximately 90 degrees

to the tongue or groove. The sleeve gaps MUST

NOT be in line with the tongue or groove.

230

Figure 230 — Connecting Rod with Alignment Sleeves

It is essential to closely control the weight of

reciprocating parts. Connecting rods fall into two

weight classes, M1 or M2. Initially, the classes

were identified by the respective “M” number (M1

or M2) stamped onto the connecting rod bearing

cap. Now, however, only the M1 rod carries the

weight class identification stamped on the rod

cap. The M2 connecting rod is no longer stamped

with the weight class identifier.

When installing a single rod, or less than a full

set, examine the removed rod(s) for part number

and M number. Installing parts with the same

weight class is preferred.

Connecting rods can be weighed to ensure that

the proper weight class is used. Connecting rod

weights for an engine should not vary by more

than 0.46 ounce (13.04 grams) within each

weight class.

The maximum weight difference between the

heaviest possible M2 rod and the lightest

possible M1 rod is 0.83 ounce (23.53 grams).

SPECIAL TOOLS REQUIRED

앫 Piston Pin Bushing Remover/Installer

J 37717

앫 Piston Pin Burnishing Broach J 37718

앫 Connecting Rod Fixture 945-6041

INSPECTION

Inspect each connecting rod for the following

conditions. If any rod(s) is suspected of being

faulty, replace it.

앫 Inspect the rods for nicks, cracks, signs of

overheating, bends or twisting that can

cause rod failure.

앫 Inspect the bolt holes for elongation or

pulled threads.

앫 Check the mating surfaces between the rod

and cap for correct fit.

앫 Inspect the crankshaft journal bearing

surface of each rod and wrist pin bushing.

If it is determined that the condition of any part or

component is questionable or is at the limit of

tolerance, replace it. If the questionable part or

component is reused, it may fail or become out of

tolerance after a short time in operation. It is

cost-efficient to replace any questionable items

when rebuilding.

Use genuine MACK replacement parts.

1. Rod Cap

2. Bearing Insert

3. Alignment Sleeve

5-111.bk Page 223 Monday, July 10, 2006 2:26 PM

Loading...

Loading...