Page 222

REPAIR INSTRUCTIONS, PART 1

4. Set the camshaft close to the oven in which

the camshaft gear will be heated. It should

be set vertically on the floor with the front of

the shaft up. Secure the shaft so it cannot

wobble or fall over as the gear is being

installed.

5. Heat the camshaft gear to 425°F (204°C) in

an oven (preferred — an old kitchen oven is

sufficient) or on an industrial grade hot plate

used in combination with the

temperature-sensing equipment described

earlier. Adequate heating will require one to

two hours. DO NOT heat the gear for more

than two hours nor exceed 425°F (204°C) as

heat treatment may be affected.

DO NOT attempt to heat the gear with a torch.

This method will only provide localized heating,

will not permit proper expansion and may affect

heat treatment of the gear.

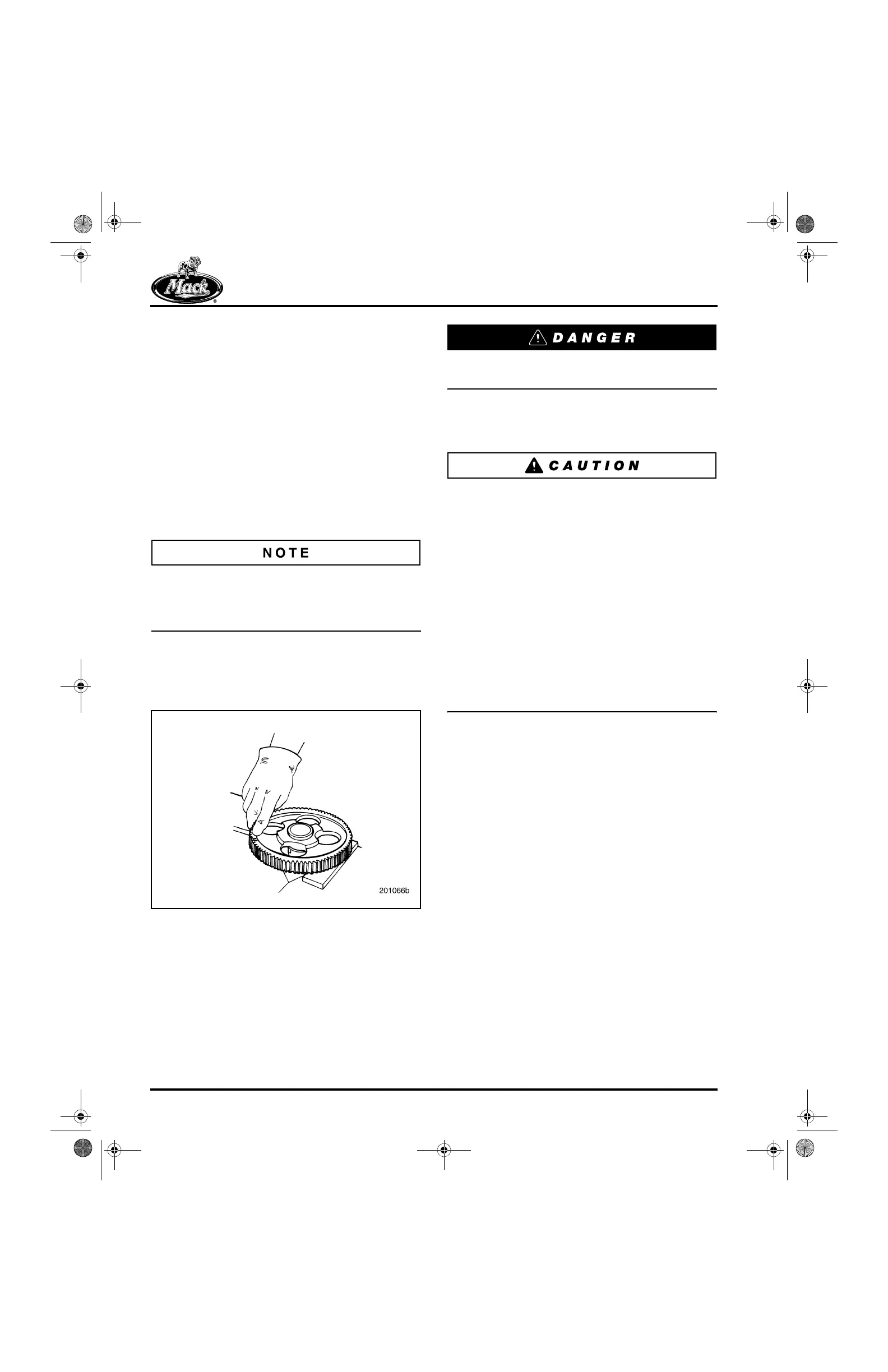

6. Remove the gear from the oven and position

it on the camshaft with the keyway and key

aligned and the timing marks facing up

(Figure 229).

229

Figure 229 — Camshaft Gear Installation, Heat Method

Wear protective gloves when handling the

heated gear.

7. Using a quick, steady motion, push

downward on the gear until the gear is fully

seated against the cam shoulder surface.

The heat-expanded gear bore will begin to

transfer heat to the camshaft as soon as contact

between the gear and shaft is made. Therefore, it

is absolutely necessary that the gear be installed

in one rapid motion to the fully seated position.

If the gear is allowed to stop on the camshaft

before it is fully seated, it will become immovable.

If this occurs, DO NOT press the gear onto the

camshaft. Instead, remove the gear with a press

and thoroughly inspect the gear bore, camshaft

journal and key. If there is no scoring, galling or

tearing, repeat the installation procedure using

the removed components. If damage is minimal,

repair the components and reinstall. If the

damage is significant, the components must be

replaced.

8. Allow the gear to cool.

9. When the gear is fully seated, there should

be 0.003–0.012 inch (0.076–0.31 mm)

clearance between the rear face of the gear

and the thrust washer. This clearance can

be measured with a feeler gauge.

5-111.bk Page 222 Monday, July 10, 2006 2:26 PM

Loading...

Loading...