Page 214

REPAIR INSTRUCTIONS, PART 1

All new service replacement crankshafts, short

blocks or basic engines will have a dowel pin in

the crankshaft rear flange. In nearly all cases, the

flywheel will already have a hole in it to accept the

dowel pin. If an earlier version flywheel or torque

converter drive flange without a dowel pin hole is

used for replacement, it must be reworked.

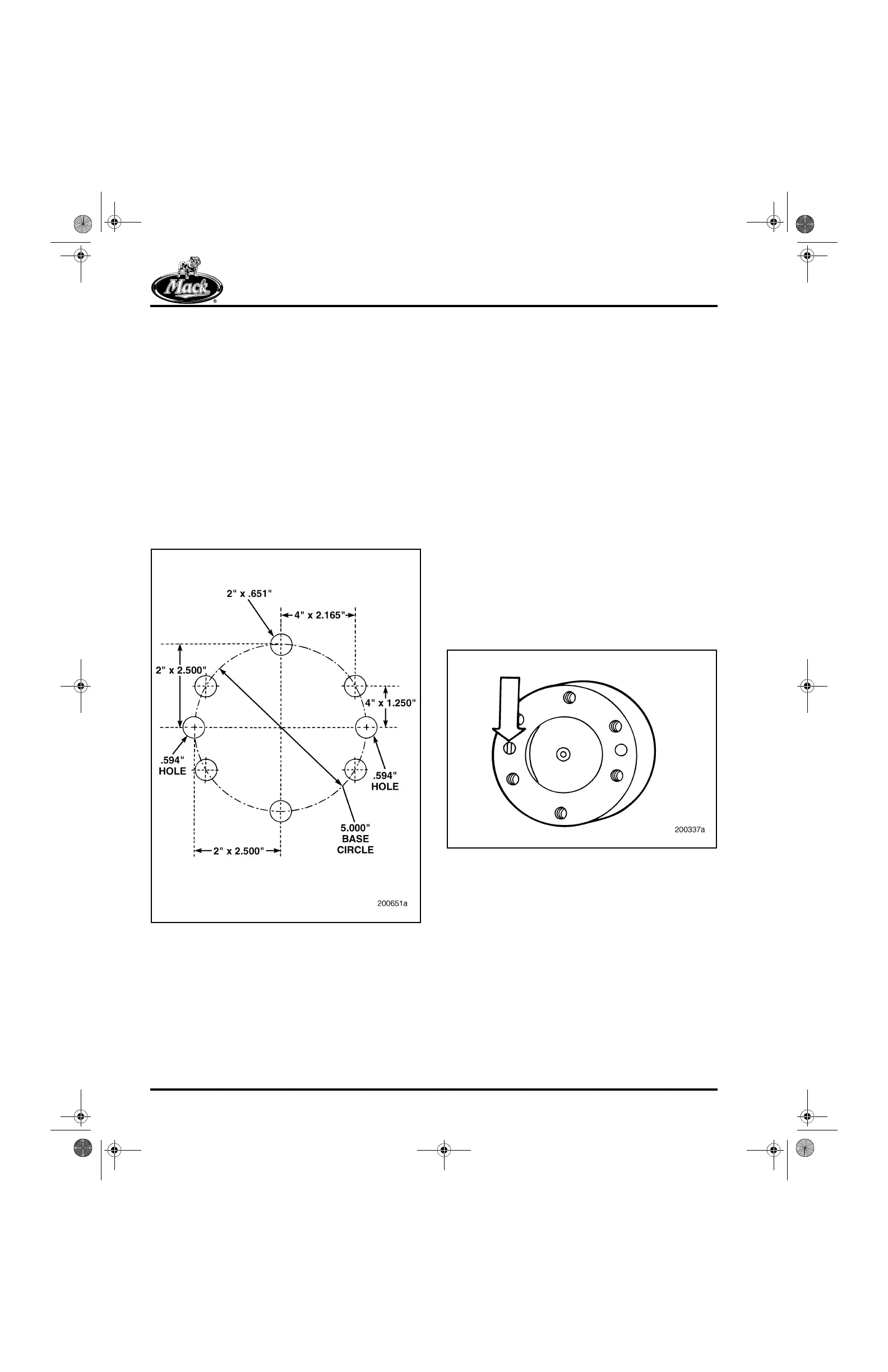

If it is necessary to rework the flywheel or torque

converter drive flange, two holes must be added

using a 19/32-inch drill bit. One hole is for the

dowel pin and another directly opposite the first

hole is to maintain balance of the flywheel/torque

converter drive flange.

Refer to Figure 219.

219

Figure 219 — Dowel Pin Hole Dimensions (Flywheel or

Torque Converter Drive Flange)

DOWEL PIN REMOVAL

To remove the crankshaft dowel pin:

1. Securely grip the dowel pin with locking

pliers.

2. Rotate the dowel pin back and forth while

exerting outward pressure until the pin is

removed.

DOWEL PIN INSTALLATION

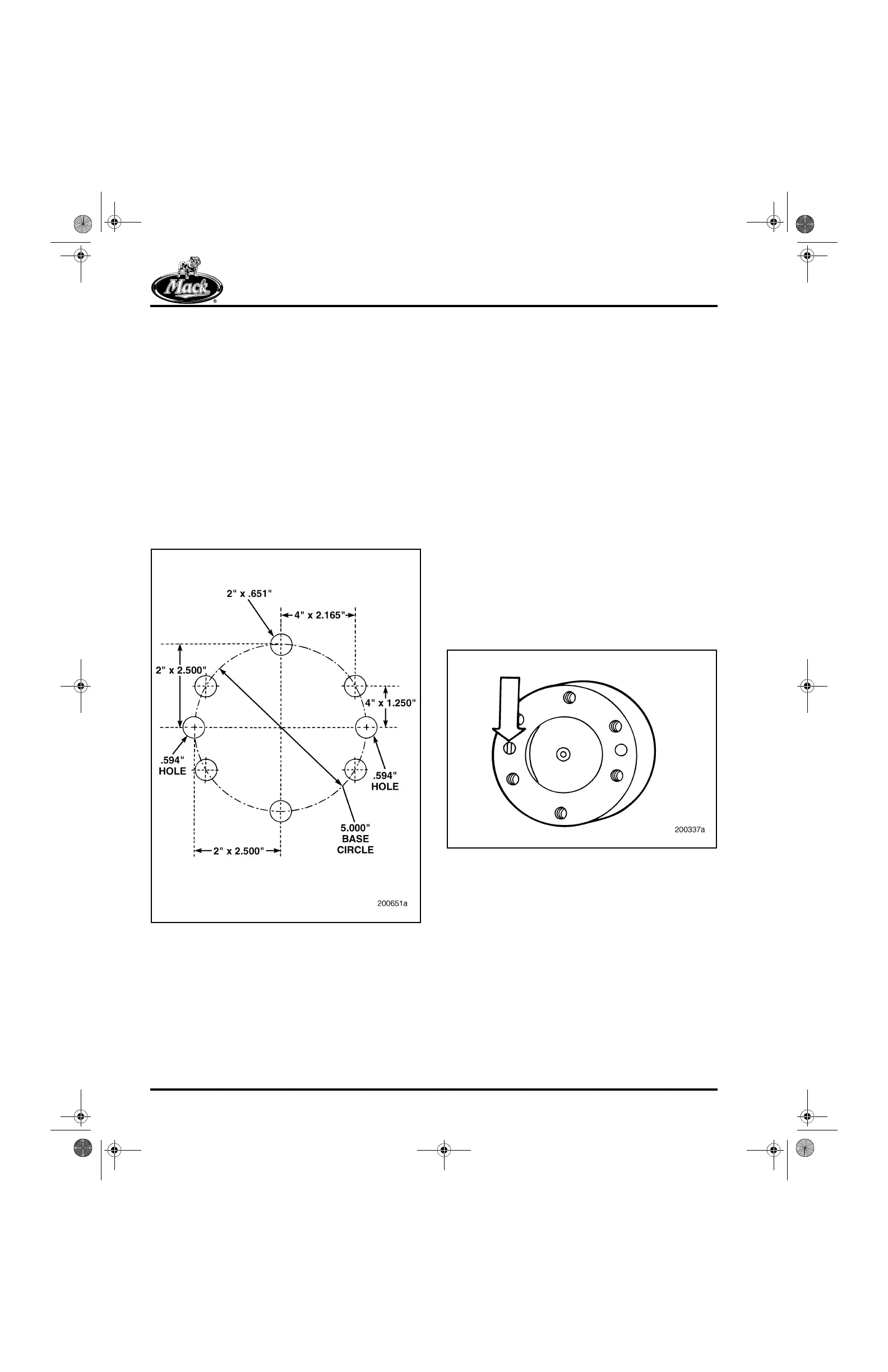

To install a replacement crankshaft dowel pin:

1. Position the dowel pin in a 0.5562-inch

(14.1275 mm) diameter unthreaded hole in

the rear flange of the crankshaft. The pin

must be installed with the flat surface

aligned parallel to the center of the

crankshaft as shown in Figure 220.

2. Use a soft metal hammer and punch to drive

the pin into the hole. The pin must be firmly

seated and protrude 0.77 inch (19.56 mm)

from the crankshaft flange surface.

220

Figure 220 — Dowel Pin Alignment

Crankshaft Gear Replacement

[212 HV]

INSPECTION

After inspecting the crankshaft and determining

that it is within specification, inspect the

crankshaft gear for cracks and broken, worn or

chipped teeth. If the gear is defective, it must be

replaced.

5-111.bk Page 214 Monday, July 10, 2006 2:26 PM

Loading...

Loading...