Page 226

REPAIR INSTRUCTIONS, PART 1

Piston Inspection and Cleaning

[212 NP]

SPECIAL TOOLS REQUIRED

앫 Piston Ring Expander PT6587

앫 Keystone Ring Groove Gauge J 29510

DISASSEMBLY

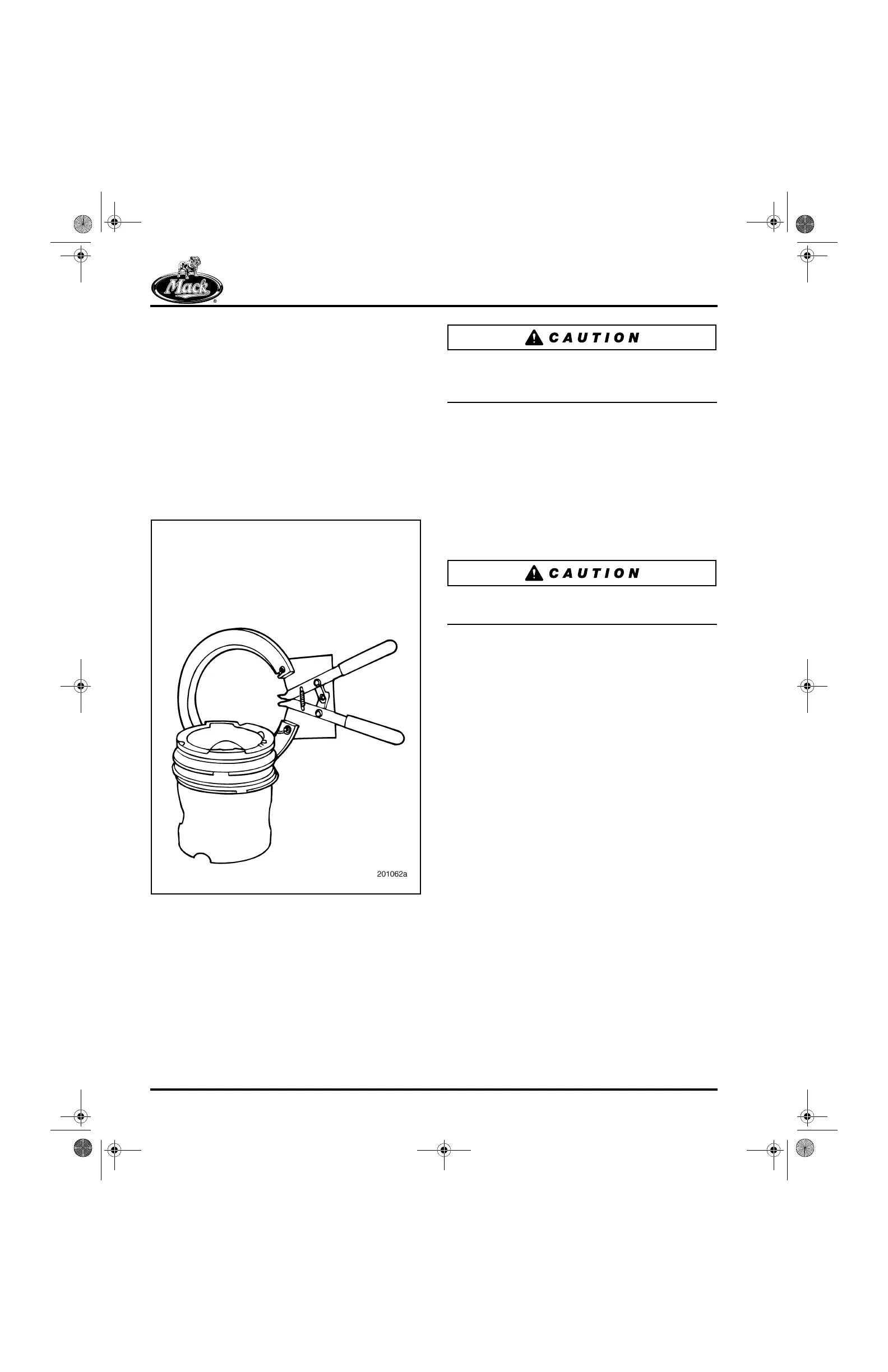

1. Using piston ring expander PT6587, remove

the piston rings (Figure 234).

234

Figure 234 — Piston Ring Removal

2. Thoroughly clean the piston ring grooves,

combustion bowl area and the snap ring

grooves. All carbon must be removed.

Carbon left in the piston ring grooves will

reduce ring clearance and prevent the

replacement rings from seating properly.

Be sure that the cleaning solvent is approved for

steel and aluminum. Incompatible solvents may

cause damage to the pistons or skirts.

3. Clean the pistons with the approved solution

and a brass brush. Take care to avoid

damaging the pistons while cleaning.

INSPECTION

Inspect the piston ring grooves, lands, piston skirt

and combustion bowl for wear, scuffing, cracks or

blow-by. Pistons are NOT repairable. Discard the

piston if it is worn or damaged.

Do not stamp or engrave on the TOP of the

piston. Doing so will reduce piston life.

To ensure that pistons are reinstalled in the same

cylinders, the pistons must be tagged with the

corresponding cylinder number when removed

during disassembly.

Piston Ring Replacement

[212 NV]

Before installing the piston rings, check the

keystone ring groove wear and ring end gap

using the following procedures.

RING END GAP CHECK

1. Place a piston ring in the cylinder sleeve.

Push it down into the sleeve with an inverted

piston to ensure that it is positioned squarely

in the sleeve.

2. Using thickness gauges, check the ring end

gap. Refer to Fits and Limits in the

SPECIFICATIONS section for end gap

tolerance. All rings to be used should be

checked in this manner.

5-111.bk Page 226 Monday, July 10, 2006 2:26 PM

Loading...

Loading...