Page 320

REPAIR INSTRUCTIONS, PART 1

MANIFOLD INSTALLATION

1. Install the 12 new studs from the MACK

Parts System in position on the cylinder

head. Studs must be installed dry (no

lubrication). Tighten the studs to the

specified torque while maintaining

mandatory stud protrusion of 1.75 inches

(44.45 mm).

2. Place six new manifold gaskets in position

on the studs.

3. Place the exhaust manifold in position on the

mounting studs. Oil the nut threads and

flanges with clean engine oil and install the

12 retaining nuts.

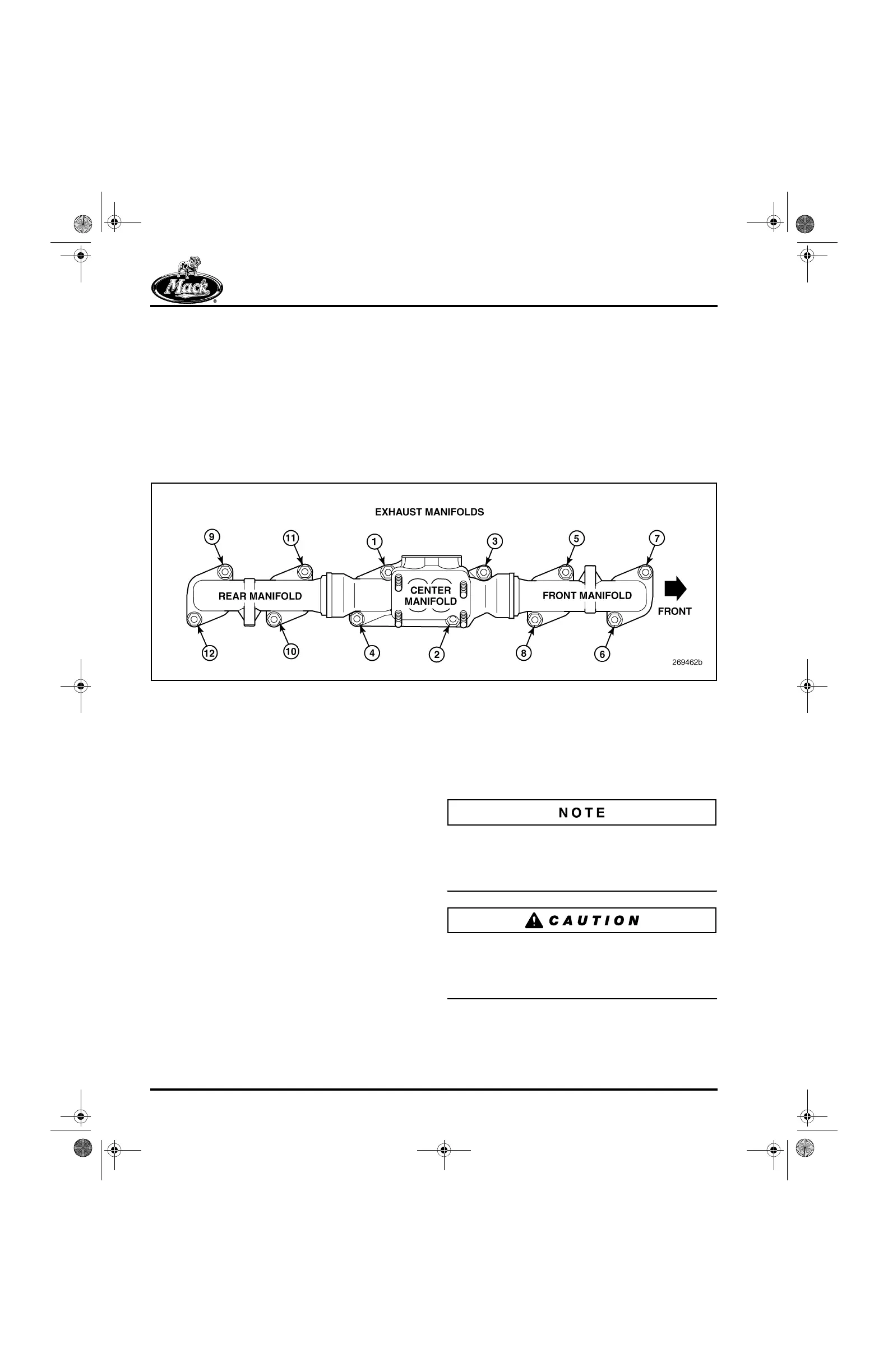

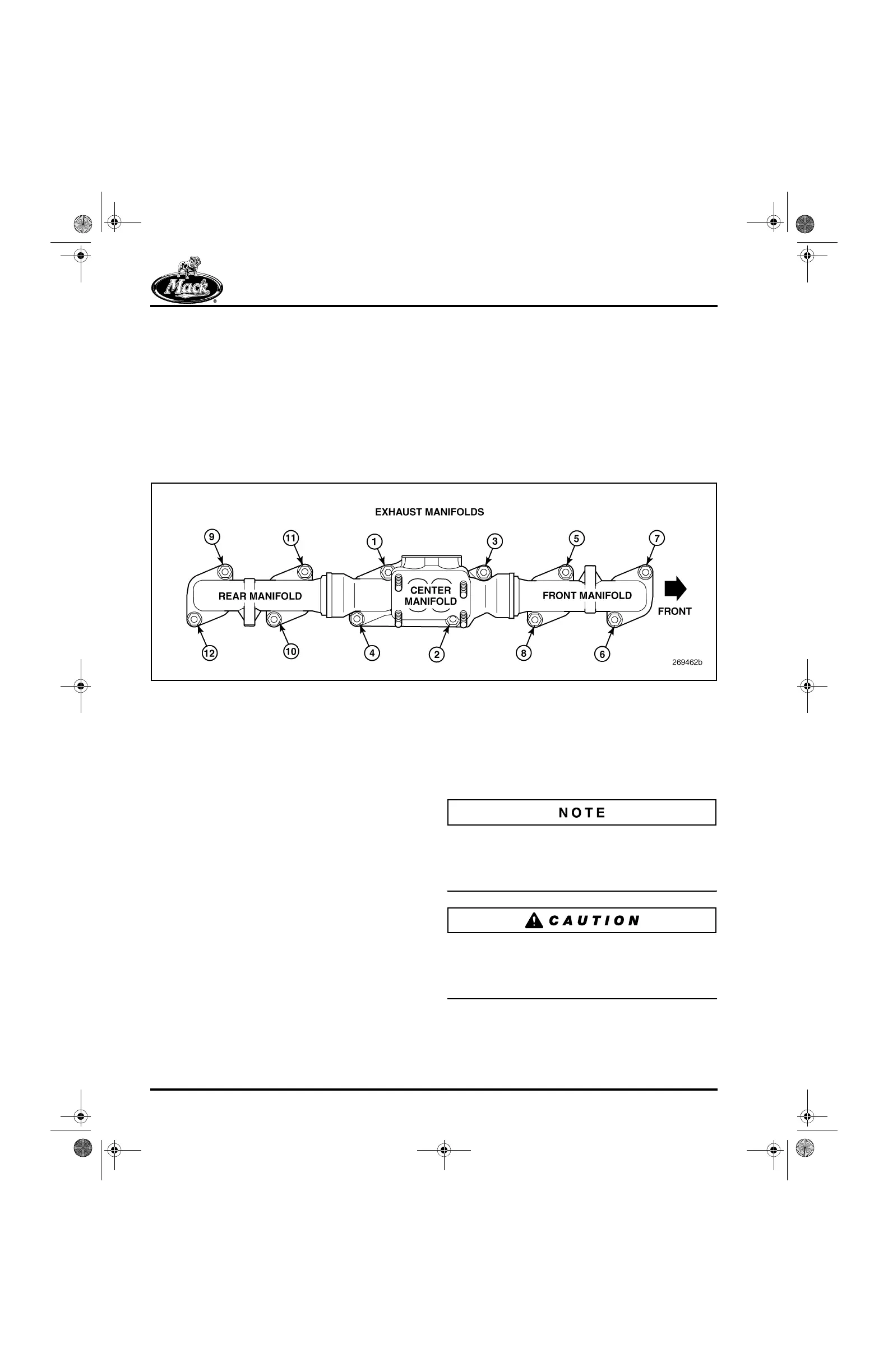

4. Tighten the nuts in two stages following the

sequence shown in Figure 370:

앫 First stage — 50 lb-ft (68 N폷m)

앫 Second stage — 100 lb-ft (136 N폷m)

370

Figure 370 — Exhaust Manifold Tightening Sequence

Nozzle Holder Assembly Installation

[222 KG]

GENERAL INFORMATION

The nozzle holder is positioned vertically in the

cylinder head and centered in the cylinder

between the four valves. The nozzle fuel inlet

tube is inserted through the side of the cylinder

head with the tapered end of the inlet tube

sealing the area between the tube and the nozzle

holder. The tube is secured in position with a

sleeve nut.

SPECIAL TOOL REQUIRED

앫 Injection Nozzle Puller J 37093

INSTALLATION PROCEDURE

1. Install the washer-type gasket in place on

the bottom of the nozzle, using a small dab

of grease to hold it in place (recommended

method).

An alternate method is to drop the washer-type

gasket into the nozzle holder sleeve bore as

shown in Figure 371. Make sure that the gasket is

centered and lying flat in the bottom of the bore.

Care must be taken with either method of

installation to NOT misposition the gasket. If

mispositioned, the washer may be damaged and

result in severe combustion leakage.

5-111.bk Page 320 Monday, July 10, 2006 2:26 PM

Loading...

Loading...