REPAIR INSTRUCTIONS, PART 1

Page 339

To avoid O-ring damage, the cam lobe must be

positioned with the base circle up prior to

installation of each EUP. Engine barring tool (tool

No. J 3857-A) MUST be used to rotate the

engine. DO NOT use the starter to rotate the

engine.

397

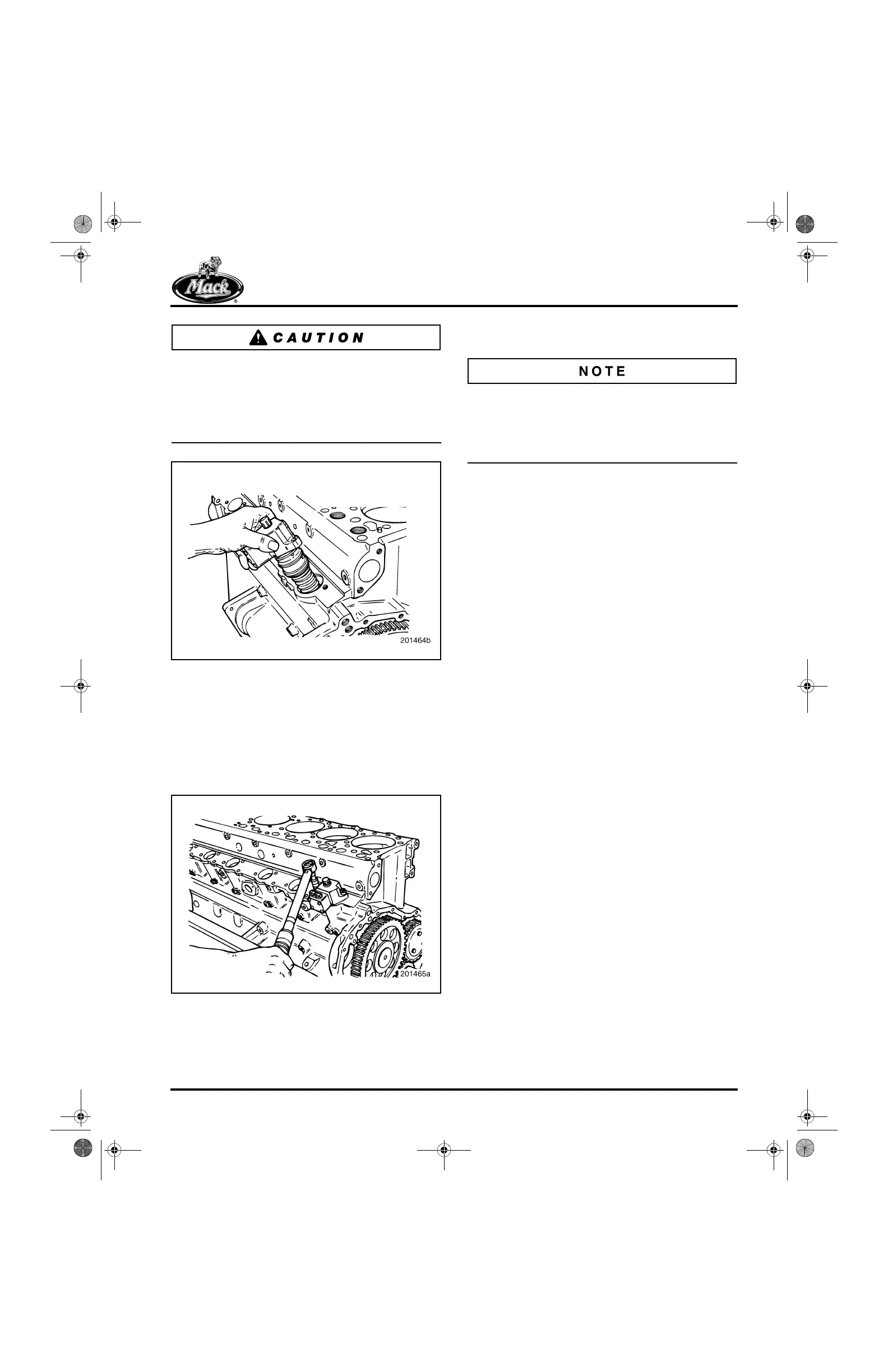

Figure 397 — Unit Pump Installation

3. Install new mounting screws. Lubricate the

threads and underside of each screw with

clean engine oil prior to installation. Tighten

the screws evenly to draw the EUP into the

cylinder block (Figure 398). Final tighten the

screws to the specified torque, 60 lb-ft

(81 N폷m).

398

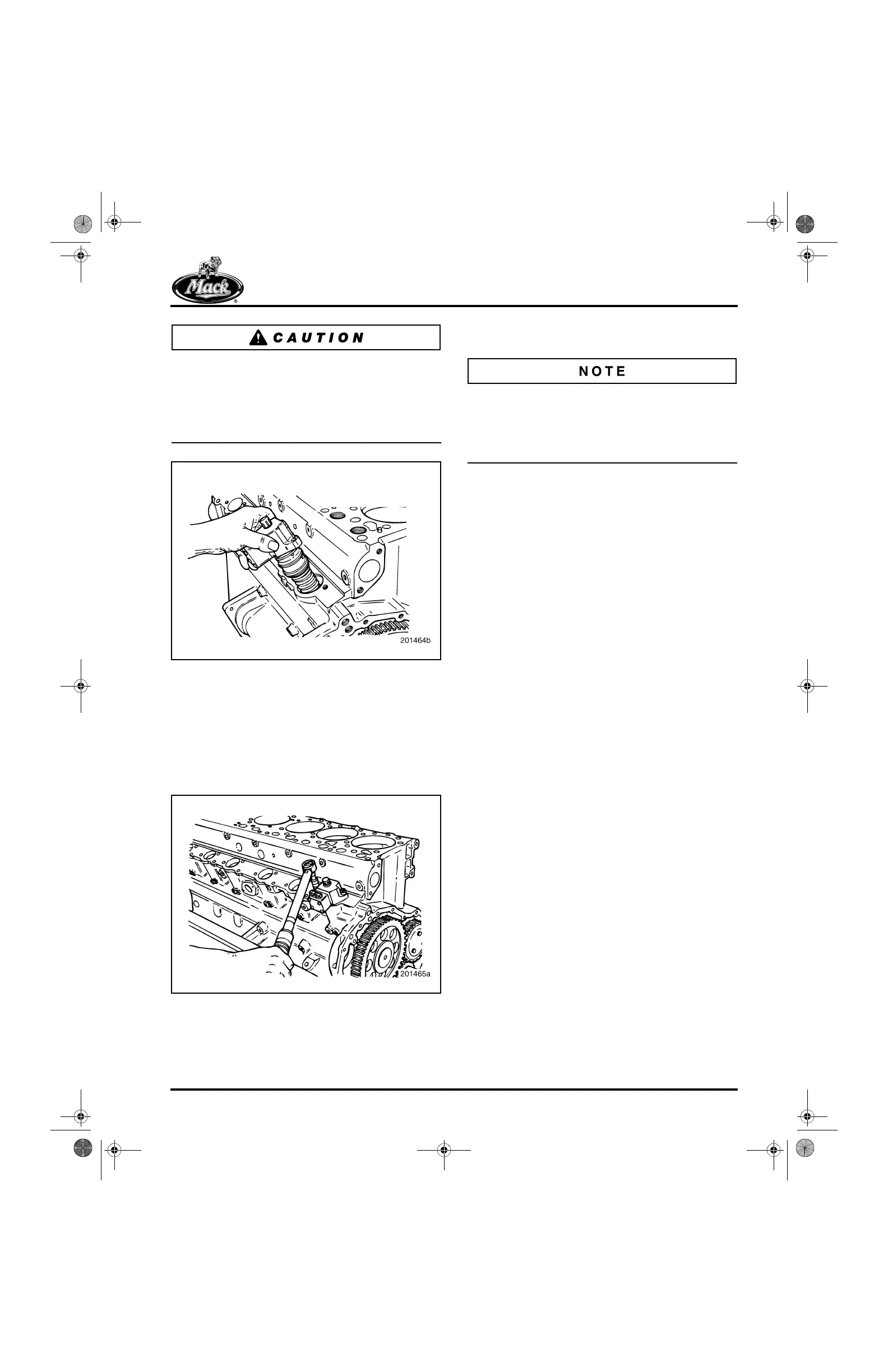

Figure 398 — Tightening Unit Pump Fasteners

4. Repeat steps 2 and 3 to install the five

remaining EUP assemblies.

If an EUP has been replaced with a new unit, the

new unit must be calibrated as described under

“Engine Setup and Adjustments” in the REPAIR

INSTRUCTIONS section. Calibration of the unit

pumps ensures optimum engine performance.

Engine Wiring Harness Installation

1. Place the wiring harness in position on the

engine and secure it with the attaching

hardware.

2. Connect the harness at each of the EUP

terminals.

3. Connect the harness at the EECU. Make

sure the locking tabs are in place.

4. Connect the harness to any sensors or other

components now installed or as reassembly

progresses.

Fuel Nozzle Inlet Tube Assembly

Installation

[222 KD]

The fuel nozzle inlet tube assemblies are

identical for all six cylinders and are installed in

the same way. Refer to Figure 400.

1. Place the EGR heat shield in position over

the front section of the exhaust manifold

(Figure 401). Install the top capscrew

attaching the shield to the cylinder block and

tighten it to specification. DO NOT install the

bottom capscrews at this time.

2. Inspect the high-pressure fuel lines before

installation. If the collars of any of the

high-pressure lines are “mushroomed” or

exhibit other types of damage, replace with a

new fuel line. An example of a mushroomed

collar is shown in Figure 399.

5-111.bk Page 339 Monday, July 10, 2006 2:26 PM

Loading...

Loading...