REPAIR INSTRUCTIONS, PART 2

Page 417

INSTALLATION PROCEDURE

Refer to Figure 506.

1. Place the EGR valve heat shield in position

over the front section of the exhaust

manifold.

2. Lubricate the fuel nozzle inlet tube clamping

screw threads for each assembly before

installing.

3. Install the No. 1 fuel nozzle inlet tube

assembly into the cylinder head until light

contact is made with the nozzle holder.

Lightly tighten the clamping screw.

4. Connect the line at the No. 1 unit pump.

Tighten the clamping screw to the specified

torque using torque wrench J 24407, or

equivalent.

앫 Line clamping screw at cylinder head:

35 lb-ft (47 N폷m)

앫 Line nut at EUP: 25 lb-ft (34 N폷m)

5. Repeat steps 3 and 4 to install the fuel

nozzle inlet tube assembly at the No. 2

cylinder.

6. Place the inner EUP heat shield in position

against the cylinder block. The bottom

flange of the lower EGR heat shield fits

between the EUP heat shield and the block.

7. Install the four capscrews to secure the inner

EUP heat shield. Tighten the capscrews to

specification, 15 lb-ft (20 N폷m).

8. Install the outer EUP heat shields and

retaining nuts. Tighten the nuts to

specification, 15 lb-ft (20 N폷m).

EGR Gas Mixer Tube Removal and

Installation

REMOVAL PROCEDURE

1. Disconnect the electrical leads to the

CMCAC outlet pressure and temperature

sensors.

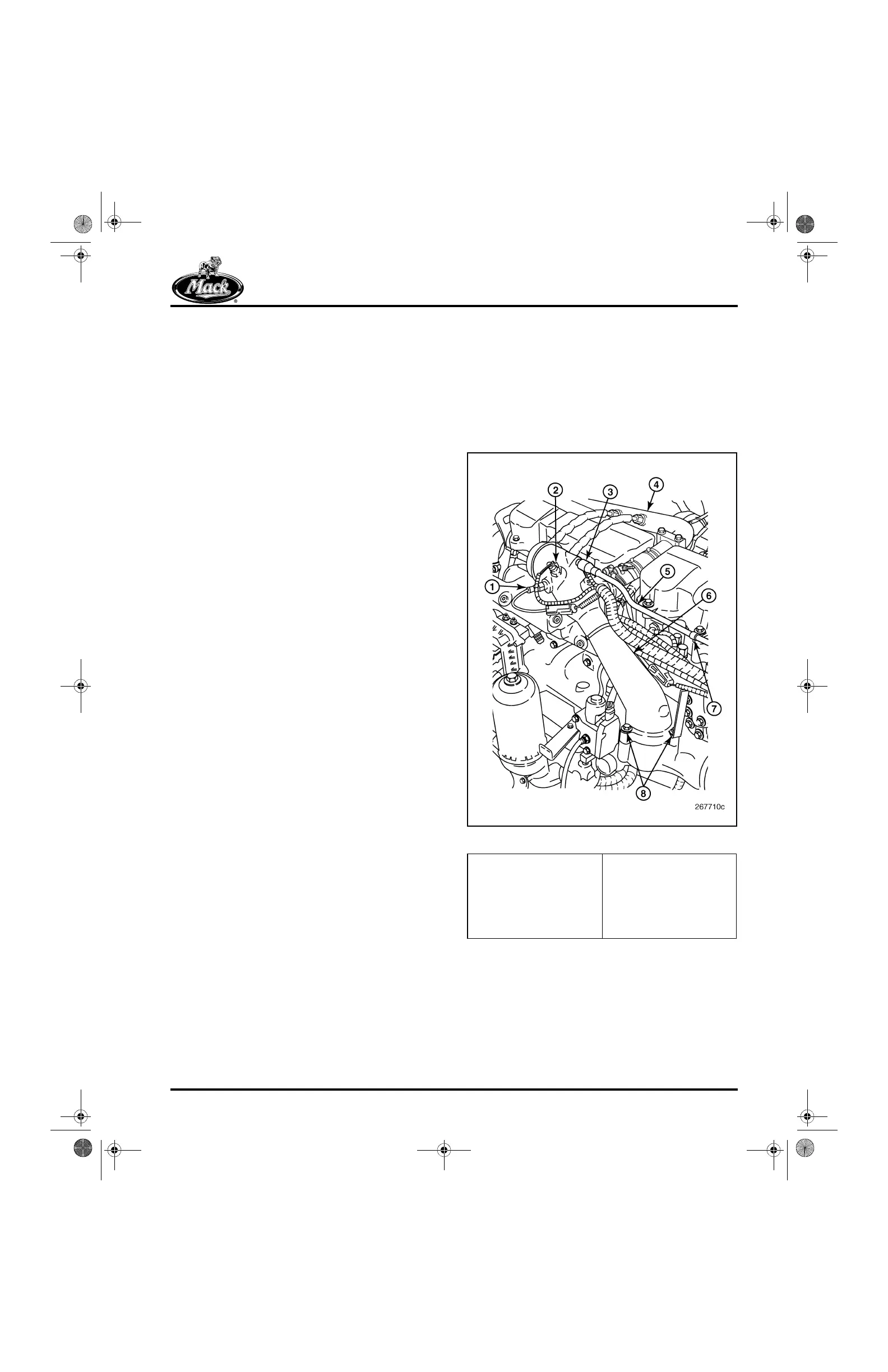

507

Figure 507 — EGR Gas Mixer Tube

2. Loosen the two band clamps securing the

flexible tapered boost pressure relief valve

(turbo by-pass) coupling hose. Remove the

two clamps and coupling hose.

1. CMCAC Pressure

Sensor

2. CMCAC Temperature

Sensor

3. Boost Pressure Relief

Valve (Turbo By-Pass)

4. EGR Cool Tube

5. Boost Pressure Relief

Outlet Tube

6. Mixer Tube

7. Boost Pressure Relief

Outlet Tube Clamp

8. Capscrews

5-111.bk Page 417 Monday, July 10, 2006 2:26 PM

Loading...

Loading...