Page 286

REPAIR INSTRUCTIONS, PART 1

ENGINE REASSEMBLY

General Instructions

This section includes step-by-step procedures for

complete reassembly of the engine. Major

components that were inspected and overhauled

or replaced under the respective bench

procedure sections of this manual are reinstalled

here as assemblies.

Failure to follow the sequence of operations listed

may result in damage to components or personal

injury.

After cleaning the components, properly store

them where they will remain clean until needed

for reassembly.

When required for installing components, be sure

to use clean engine oil of the approved type.

Crankshaft Installation

[212 HP]

1. Be sure that the crankshaft and the

crankcase area of the cylinder block are

clean.

2. Thoroughly clean each main bearing bore

and the back of each bearing insert before

installation. The inserts must be installed

dry.

The hole in the insert must line up with the drilled

hole in the block or the bearing will fail due to lack

of lubrication. The upper bearing insert is

stamped on the back with the word “UPPER.”

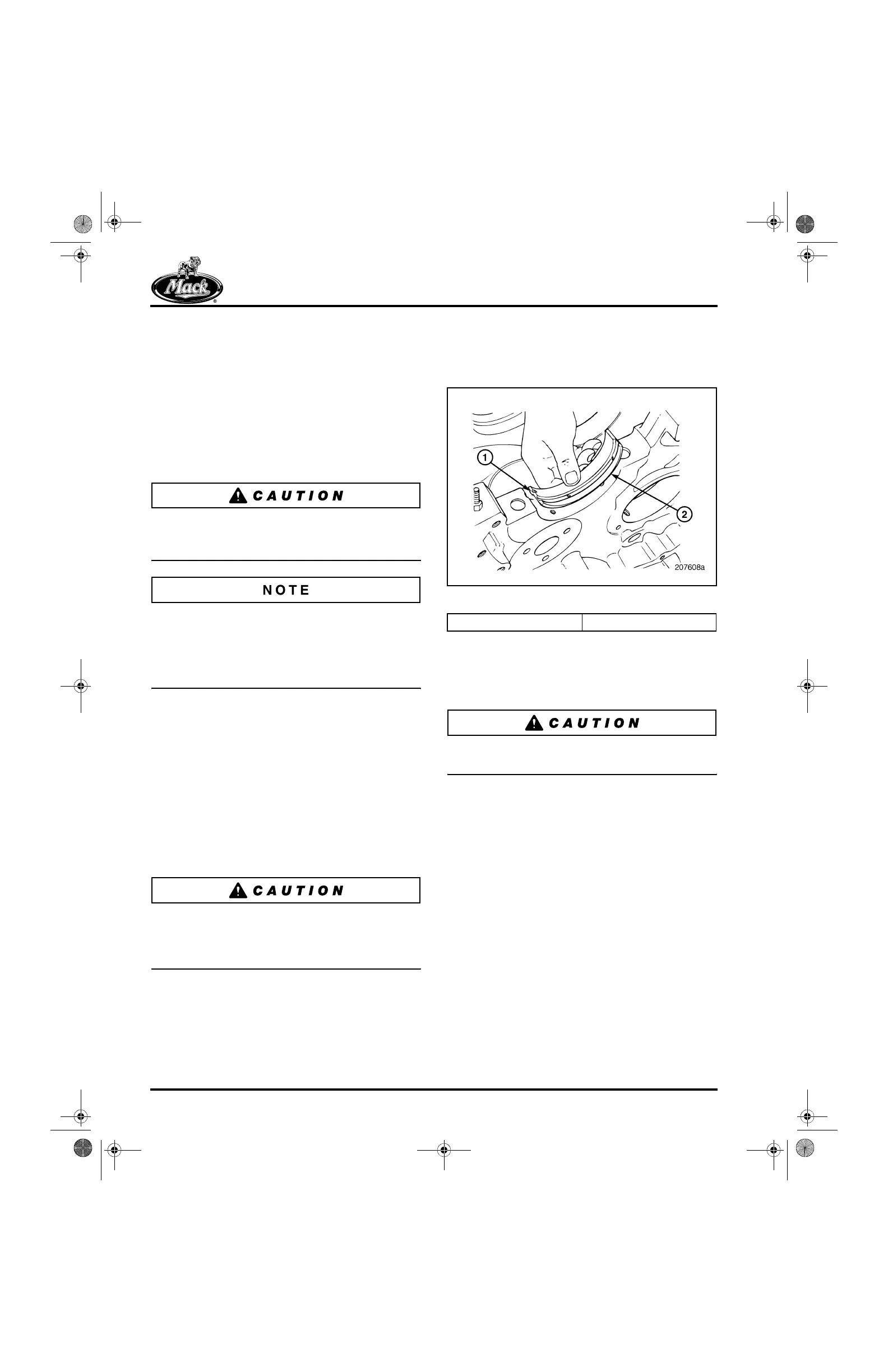

3. Place the upper half of the bearing insert in

the cylinder block main bearing bore,

making sure that the locating tab fits into the

notch in the bore (Figure 321).

321

Figure 321 — Main Bearing Insert (Upper)

4. Repeat the previous step to install the

remaining upper inserts. Refer to Figure 322

for the part number and location of each

bearing insert.

A bearing insert installed at the wrong location

can cause engine failure.

1. Locating Tab 2. Bearing Insert

5-111.bk Page 286 Monday, July 10, 2006 2:26 PM

Loading...

Loading...