Page 68

DESCRIPTION AND OPERATION

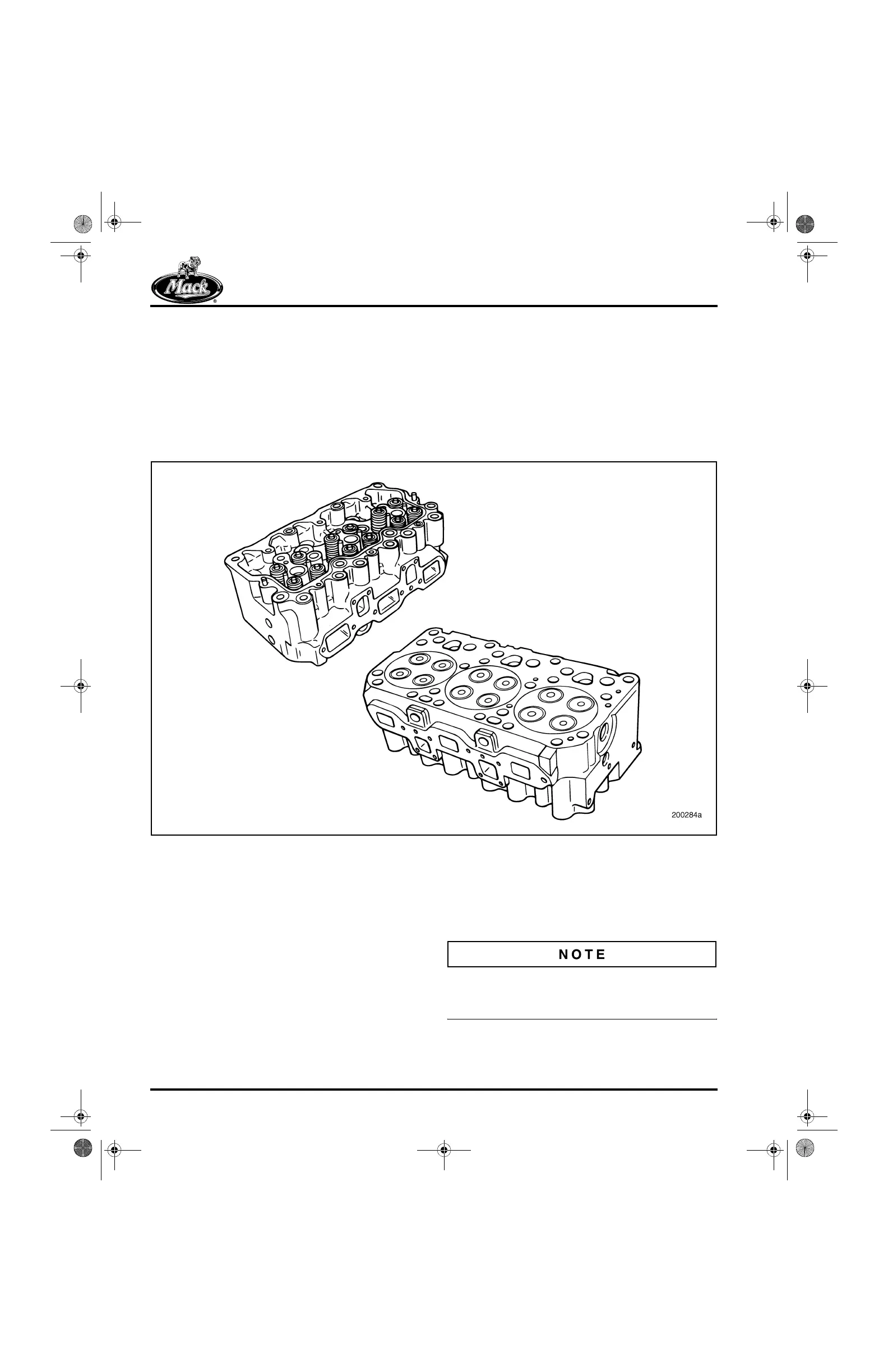

Cylinder Head

The cast-iron cylinder head (Figure 77) is

constructed using a special iron alloy. The head

contains cored inlet, exhaust and coolant

passages, drilled oil passages, replaceable inlet

and exhaust guides and seats, various drilled

passages and tapped holes. Each cylinder head

covers three cylinders and has two inlet and two

exhaust valves per cylinder. Circular grooves in

the deck surface correspond with the fire ring

bead on the cylinder sleeves. This design sets

the fire ring directly over the liner. With the

cylinder head installed and the bolts tightened to

specification, the liner coining bead extrudes the

fire ring into the cylinder head groove, providing a

positive combustion pressure seal.

77

Figure 77 — Cylinder Head

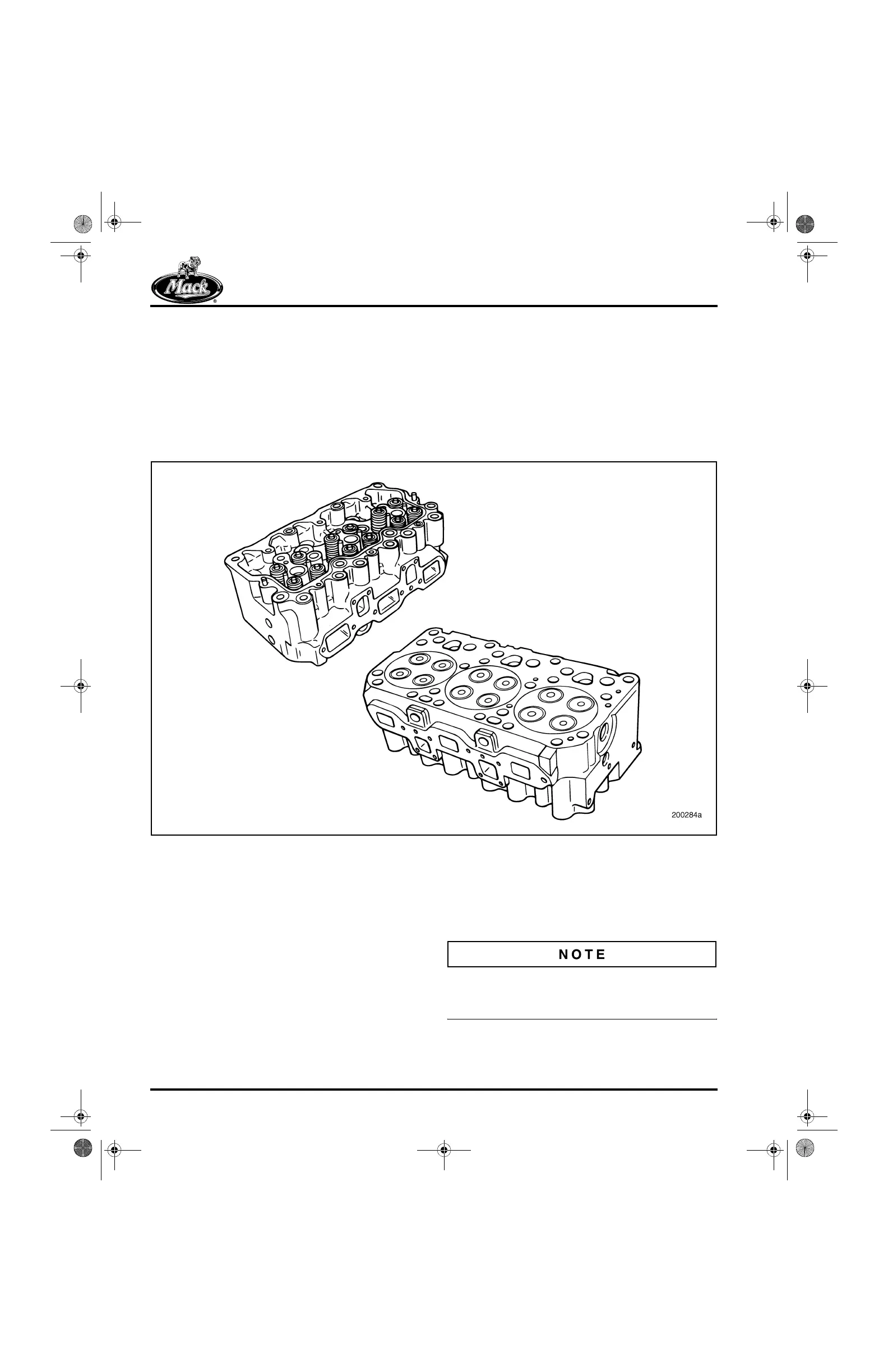

Some characteristics of the cylinder head are not

visually evident, but are still significant

(Figure 78). They include the following listed

items:

앫 Push rod holes are angled at four degrees

due to outboard location of camshaft.

앫 Large nozzle sleeve diameter to

accommodate 22 mm nozzle holder

assembly with no leak off return.

앫 Water-jacket casting designed to improve

coolant flow.

앫 Lower exhaust stud holes intersect with

push rod holes; upper exhaust holes may

intersect as well. This requires that all

exhaust studs be sealed at installation to

prevent oil weepage.

ASET™ and E7 cylinder heads cannot be

interchanged because of the differences in the

machining.

5-111.bk Page 68 Monday, July 10, 2006 2:26 PM

Loading...

Loading...