Page 342

REPAIR INSTRUCTIONS, PART 1

Turbocharger Installation

[214 SC]

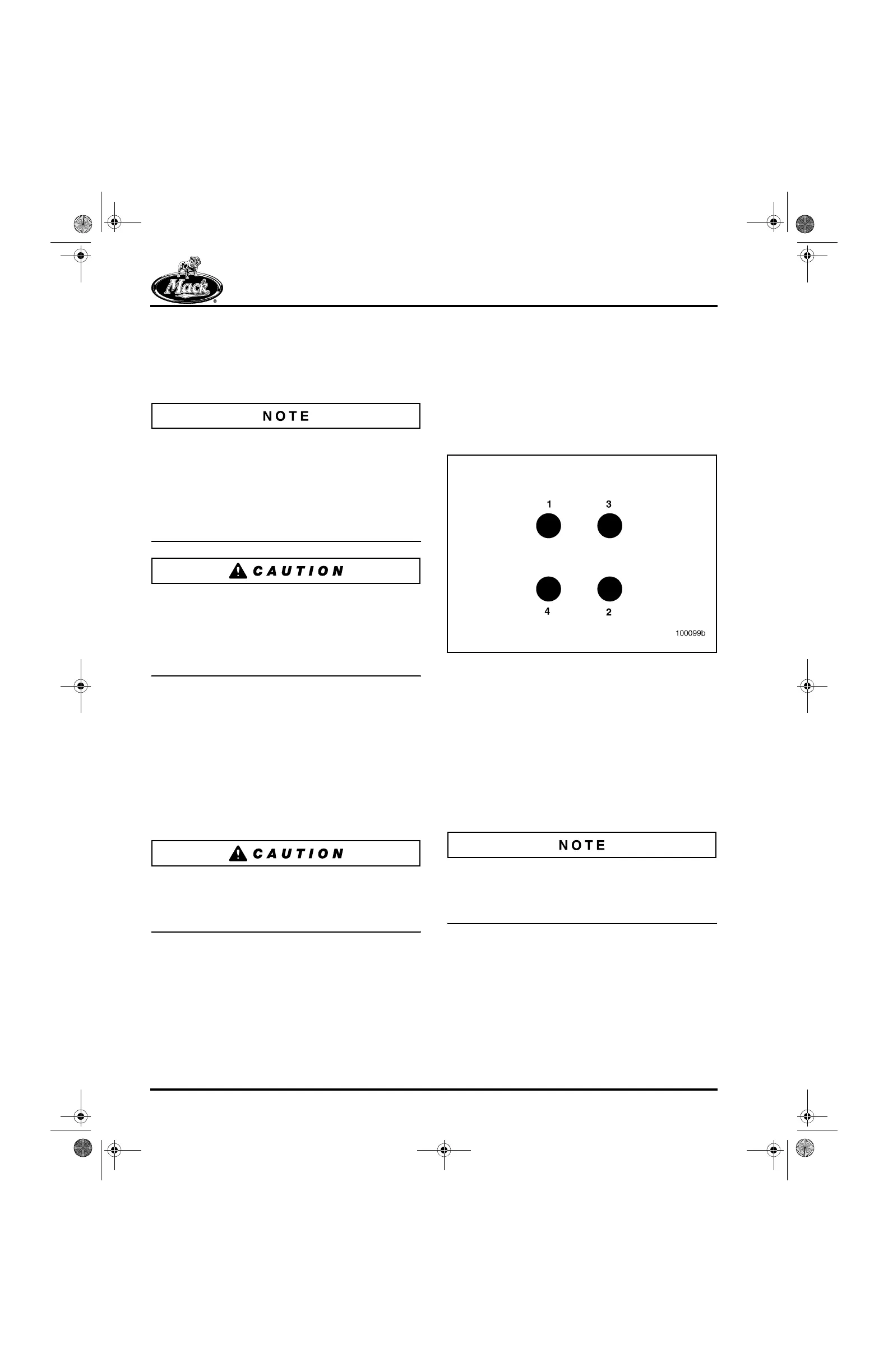

Refer to Figure 403.

A thorough inspection is required as even small

particles can cause severe rotor damage if

inducted during high-speed operation.

Use only new and approved gaskets at the

various air, oil and exhaust connections to the

turbocharger. Avoid the use of sealing or jointing

compounds at all flanged connections.

After completing the reassembly of the engine,

the turbocharger must be prelubricated with clean

engine oil before starting the engine. Refer to the

procedure under “Turbocharger” in the ENGINE

PREPARATION AND OPERATIONAL CHECK

section.

1. Inspect the intake and exhaust systems

leading to and from the turbocharger to

ensure absence of foreign material,

including burrs and loose lining fragments.

Place protective caps over the compressor

and turbine outlets to keep debris and dirt

out of the turbocharger as engine

reassembly progresses.

2. Install a new turbocharger gasket over the

four mounting studs.

The turbocharger is heavy, weighing

approximately 76 lbs. DO NOT attempt to remove

or install the turbocharger without the help of an

assistant or the use of a suitable lifting device.

3. Place the turbocharger in position over the

mounting studs on the exhaust manifold.

4. Apply a coating of clean engine oil to the

flanges and threads of the four nuts. Install

the nuts and using torque wrench J 24406,

or equivalent, tighten the nuts in a

cross-pattern sequence (Figure 402) in two

stages:

앫 First stage — 50 lb-ft (68 N폷m)

앫 Second stage — 100 lb-ft (136 N폷m)

402

Figure 402 — Turbocharger Tightening Sequence

5. Inspect the turbocharger oil supply line to

make sure it is flushed clean and free of all

debris. Then, install the supply line.

6. Place the oil drain tube in position between

the port on the engine block and the

turbocharger. Apply anti-seize compound to

the threads of the capscrews and install the

capscrews. Tighten the capscrews to the

specified torque, 15 lb-ft (20 N폷m), using

torque wrench J 24406, or equivalent.

If the VTG actuator has been removed, refer to

“VTG TURBOCHARGER SERVICE

PROCEDURES (ASET™ AC ENGINE)” for

installation and adjustment procedures.

5-111.bk Page 342 Monday, July 10, 2006 2:26 PM

Loading...

Loading...