Page 426

REPAIR INSTRUCTIONS, PART 2

Turbocharger Installation (Includes

Pre-Lubing Procedures)

1. Inspect the intake and exhaust systems

leading to and from the turbocharger to

ensure absence of foreign material,

including burrs and loose lining fragments.

A thorough inspection is required as even small

particles can cause severe rotor damage if

inducted during high-speed operation.

2. Use new and approved gaskets at the

various air, oil and exhaust connections to

the turbocharger. Avoid the use of sealing or

jointing compounds at all flanged

connections.

The turbocharger-to-manifold gasket is unique for

the VTG turbocharger. When installing the

turbocharger, be sure to use the correct gasket;

the gasket used with a standard turbocharger will

not work for this application.

The turbocharger is heavy, weighing

approximately 76 lbs. DO NOT attempt to remove

or install the turbocharger without the help of an

assistant or the use of a suitable lifting device.

3. Place the turbocharger in position over the

mounting studs on the exhaust manifold

(Figure 516).

4. Apply a coating of clean engine oil to the

flanges and threads of the four nuts. Install

the nuts and using torque wrench J 24406,

or equivalent, tighten the nuts in a

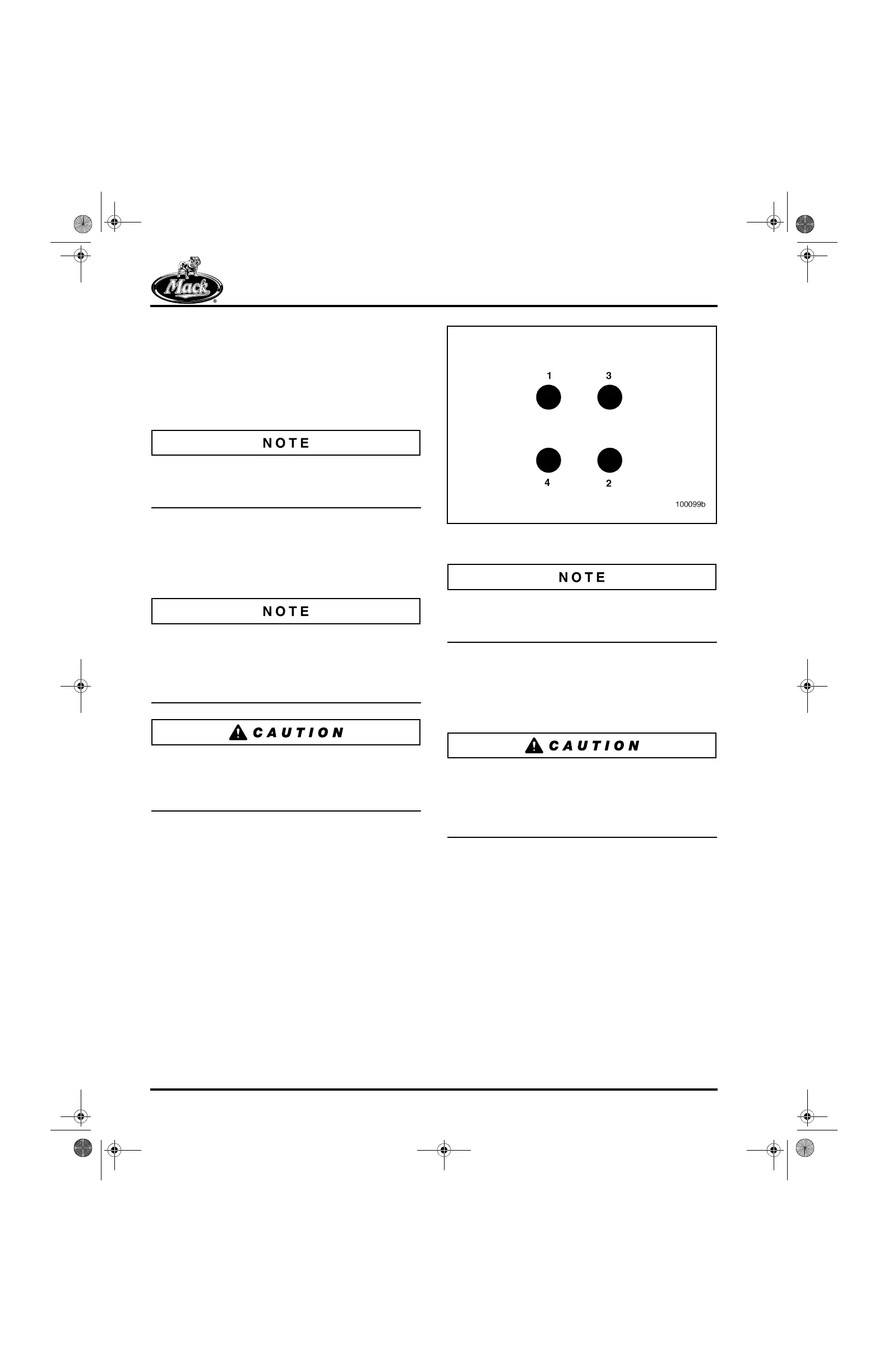

cross-pattern sequence (Figure 517) in two

stages:

앫 First stage — 50 lb-ft (68 N폷m)

앫 Second stage — 100 lb-ft (136 N폷m)

517

Figure 517 — Turbocharger Tightening Sequence

The mounting nut at the upper front location is

difficult to access and will require the use of an

offset wrench or crow’s foot to tighten.

5. Support the exhaust pipe to prevent it from

dropping onto the EGR hot tube bellows.

Then, install the exhaust bracket to the

flywheel housing and install the exhaust

clamp at the turbocharger.

DO NOT let the exhaust pipe drop onto the

bellows of the EGR hot tube as the exhaust pipe

clamp is being installed at the turbocharger. The

bellows could be damaged requiring replacement

of the hot tube.

6. Fill the oil inlet port to overflowing with clean

engine oil. Next, using your fingers at the

compressor wheel, carefully spin and wiggle

the turbocharger shaft to distribute the oil

over all bearing surfaces. Then, again fill the

oil inlet port to overflowing.

5-111.bk Page 426 Monday, July 10, 2006 2:26 PM

Loading...

Loading...