Page 340

REPAIR INSTRUCTIONS, PART 1

399

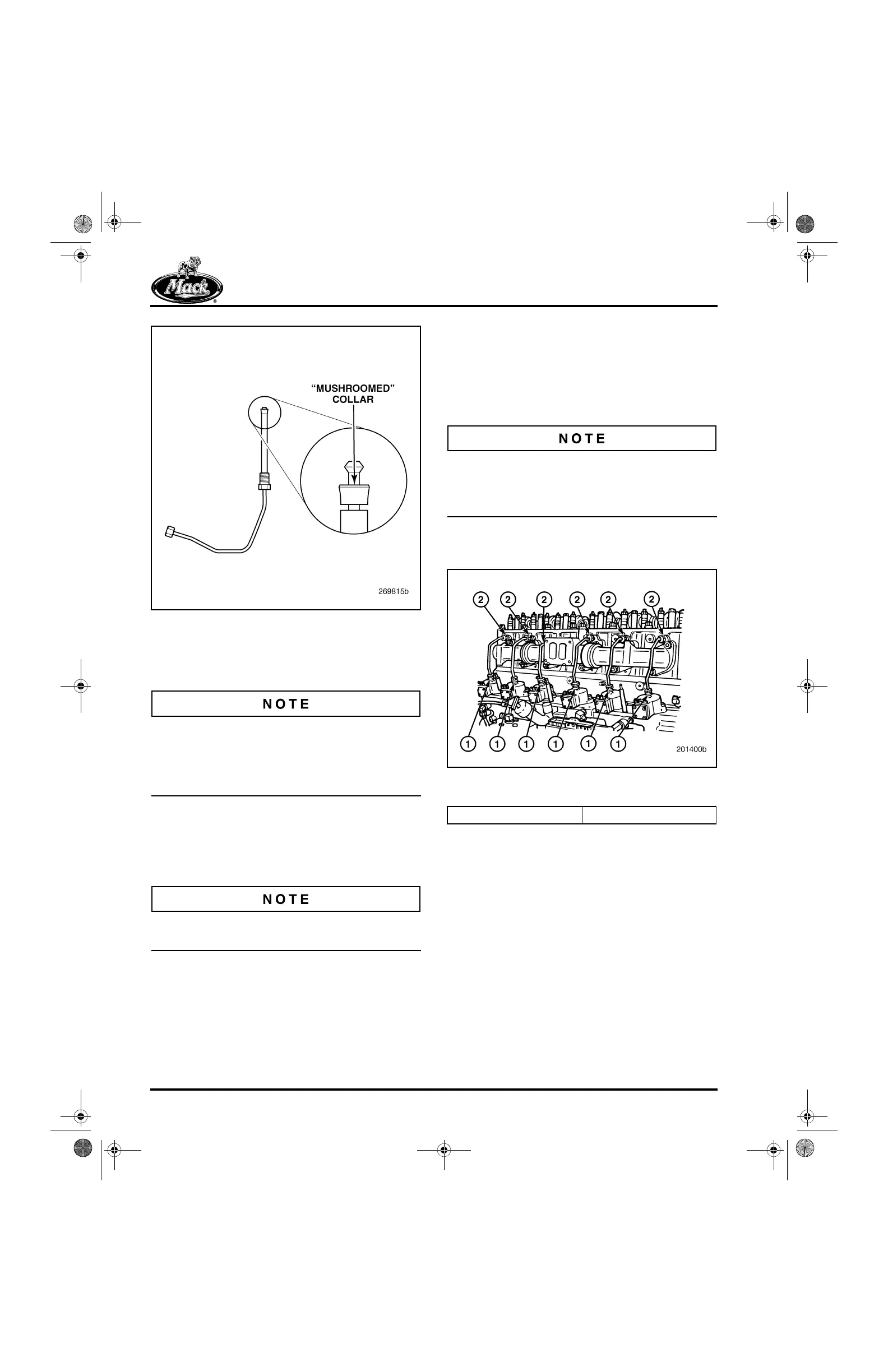

Figure 399 — “Mushroomed” Collar

3. Lubricate the nozzle inlet tube line nut

threads on each assembly before

installation.

Fuel lines should not be bent at any time during

the installation process. If lines are bent, damage

to the fuel line may result. Even bending the line

slightly and then bending it back to its original

shape can damage the line.

4. Install the No. 1 cylinder fuel nozzle inlet

tube assembly into the cylinder head until

light contact is made with the nozzle holder.

Lightly tighten the fuel inlet tube line nut

clamping screw.

The fuel inlet tube assemblies are identical for all

six cylinders.

5. Connect the line at the No. 1 unit pump.

Tighten the line nut to the specified torque,

using torque wrench J 24407, or equivalent.

앫 Line nut at cylinder head: 35 lb-ft

(47 N폷m)

앫 Line nut at EUP: 25 lb-ft (34 N폷m)

An open-ended “crow’s foot” adapter is required

with the torque wrench for installing the nozzle

fuel inlet tube assemblies. Avoid twisting the lines

when tightening the line nuts.

6. Repeat steps 1 through 3 for the five

remaining fuel nozzle inlet tube assemblies.

400

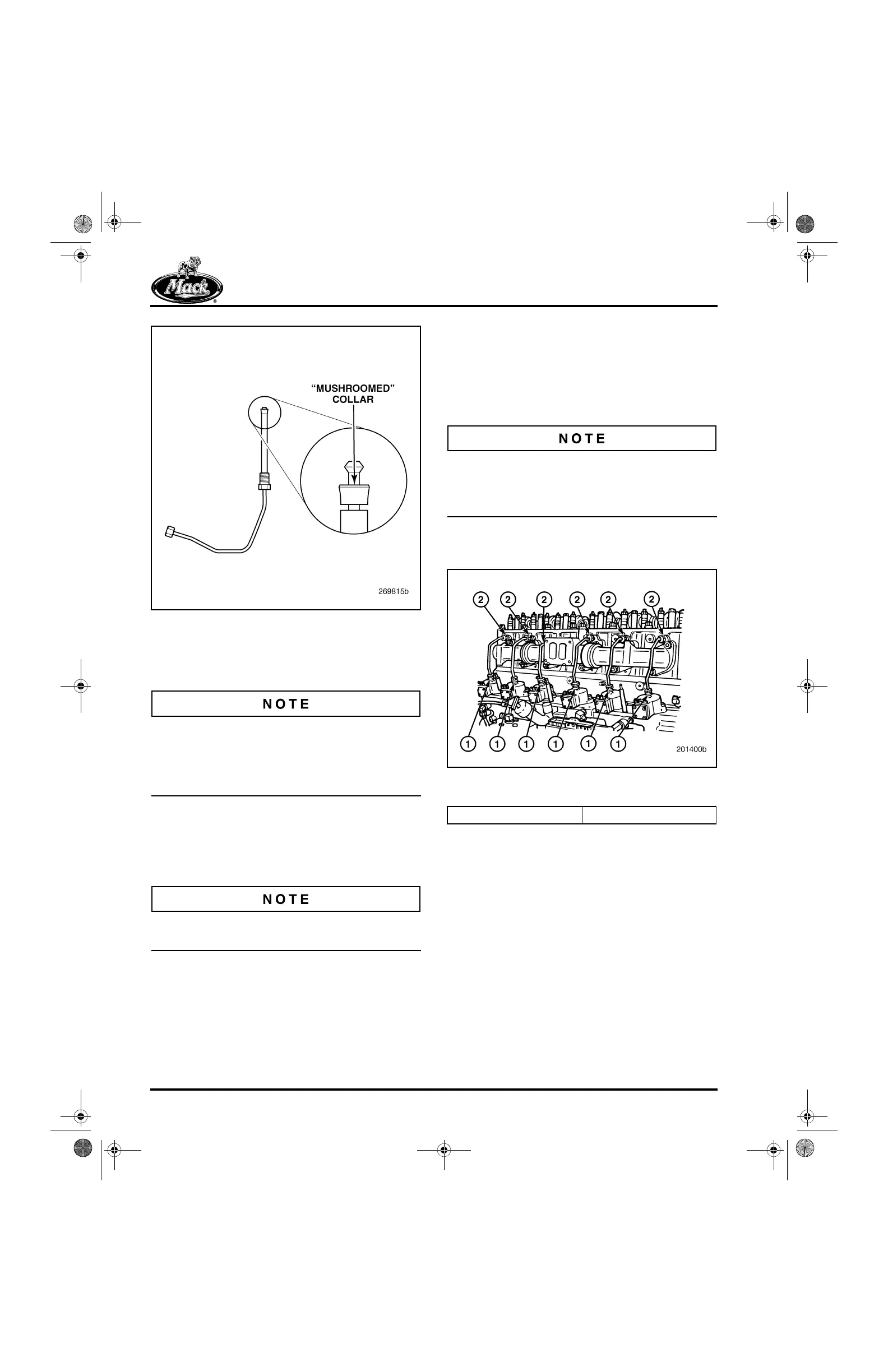

Figure 400 — Fuel Nozzle Inlet Tube Assembly

Installation

7. Place the inner EUP heat shield in position

against the cylinder block. The bottom

flange of the lower EGR heat shield fits

between the EUP heat shield and the block.

8. Install the four capscrews to secure the inner

EUP heat shield and EGR heat shield.

Tighten the capscrews to specification,

15 lb-ft (20 N폷m).

9. Install the outer EUP heat shields and

retaining nuts. Tighten the nuts to

specification, 15 lb-ft (20폷m).

1. EUP Line Nut 2. Fuel Inlet Tube Line Nut

5-111.bk Page 340 Monday, July 10, 2006 2:26 PM

Loading...

Loading...