Page 188

REPAIR INSTRUCTIONS, PART 1

SOLVENT TANK CLEANING

Use a cleaning tank large enough to

accommodate the largest component to be

cleaned. Fill the tank with a suitable solvent and

always use caution while cleaning parts. Parts

may be dried with compressed air.

1. Scrape any remaining gasket material from

the block.

2. Using a wire brush or rotary wheel, remove

any rust, corrosion or other debris from the

block.

3. Clean all other block surfaces with mineral

spirits or other suitable solvent.

4. Using due care and caution, clean and dry

the block with compressed air.

INSPECTION

A complete discussion of the proper methods for

precision measuring and inspection is outside the

scope of this procedure. However, every shop

should be equipped with standard gauges, such

as bore gauges, dial indicators, outside and

inside micrometers, thickness gauges and

straightedges.

Check the cylinder block for indications of

cracking or coolant leakage. If any damage is

suspected, use a standard dye penetrant or

magnaflux procedure to determine if cracks exist.

A cracked engine block must be replaced and

never reused.

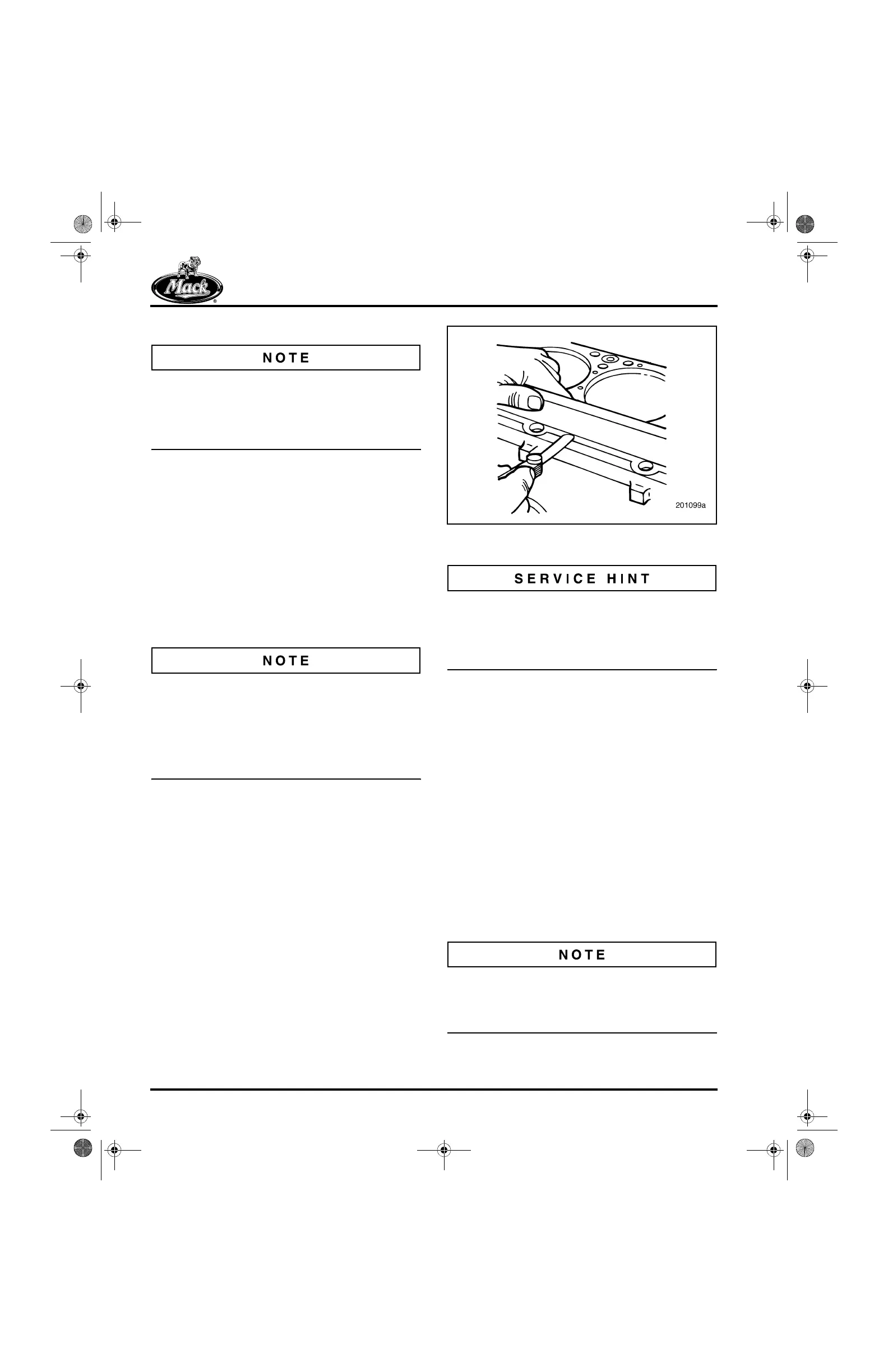

Refer to Figure 189.

Using a straightedge (PT5027 or equivalent) and

thickness gauges, check the cylinder head

mounting surfaces for flatness. The cylinder block

mounting surface on a service block should be

flat within 0.004 inch (0.102 mm) and flat within

0.002 inch (0.051 mm) over the area of each

cylinder head mounting.

189

Figure 189 — Checking Flatness of Cylinder Block Deck

If the cylinder block is determined to be

serviceable after thorough cleaning and

inspection, reassemble the engine. Use

replacement or original parts, as determined

during component inspection.

SALVAGING A DAMAGED EUP TAPPET

BORE

Occasionally, severe failure of an EUP tappet

roller and axle will result in parts of the tappet

being driven up against the bottom of the tappet

bore, causing damage to the bottom of the bore.

This damage must be repaired. Depending upon

the extent of the damage, it may be necessary to

begin with a small die grinder to remove the

displaced material, removing only the high spots

to bring them down to the remaining bore surface,

then finishing with a fine file, stone or emery

paper. The bore and adjacent areas must be

thoroughly cleaned to remove all metal particles

and abrasive material. Perform a trial-fit of the

EUP tappet and check for freedom of movement

in the bore.

Whenever a lifter bore is reworked or honed, be

sure that all the metal and honing debris is

cleaned from all affected areas by flushing with a

fresh supply of suitable brake/parts cleaner.

5-111.bk Page 188 Monday, July 10, 2006 2:26 PM

Loading...

Loading...