Page 196

REPAIR INSTRUCTIONS, PART 1

In some cases, the H-ring remover tool may not

position the collet far enough into the H-ring to

provide proper engagement for removal. If this

situation occurs, remove 0.375 inch (9.5 mm) of

the threads by grinding or cutting them down;

remove any burrs. This will allow the tool to be

positioned further into the lifter bore.

2. Inspect the cylinder block lifter bore and

place a new standard size H-ring onto the

top of the bore. The H-ring should be a

press-fit. If it is a slip-fit, an oversize H-ring is

required. Determine the oversize as follows:

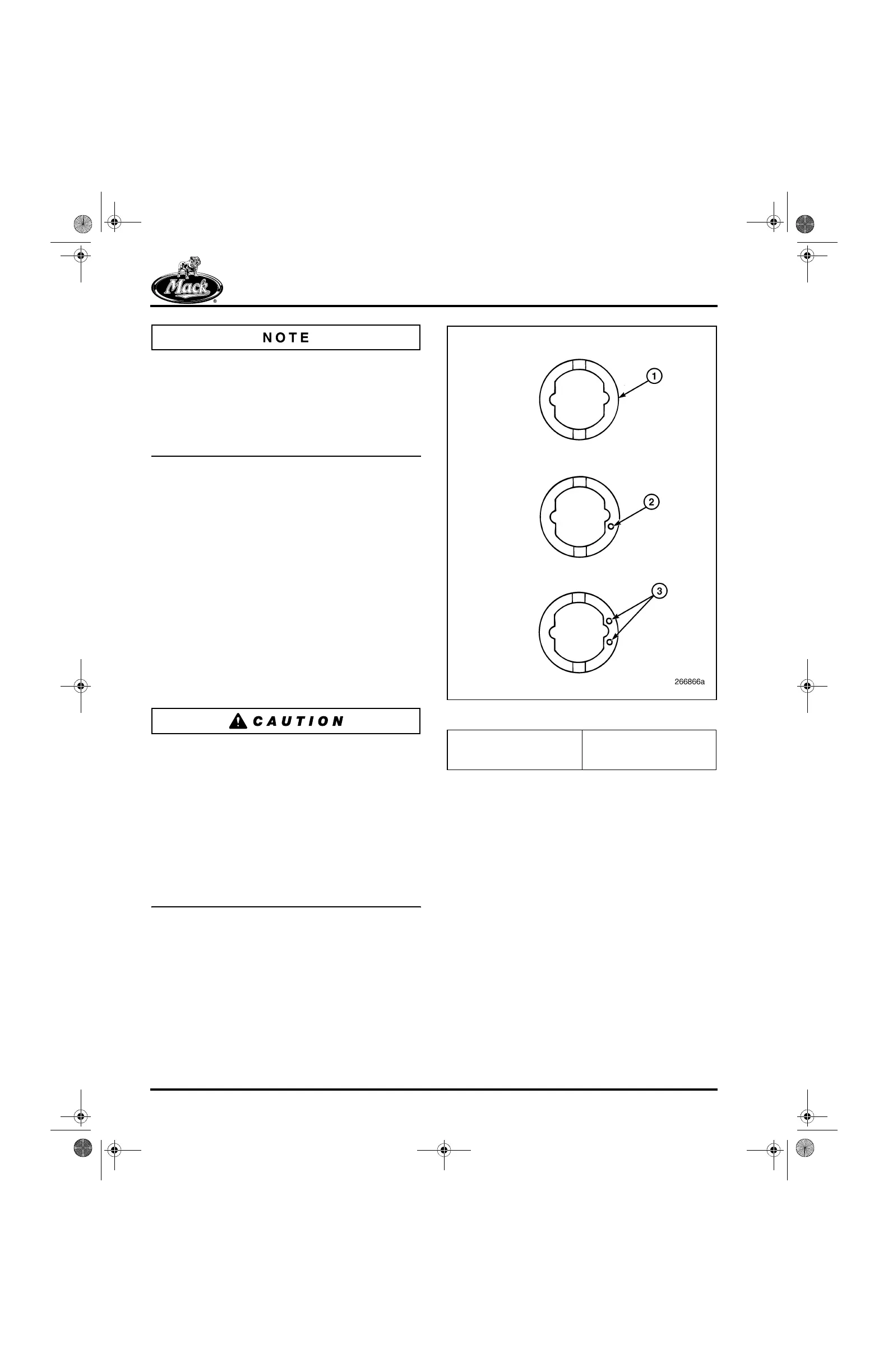

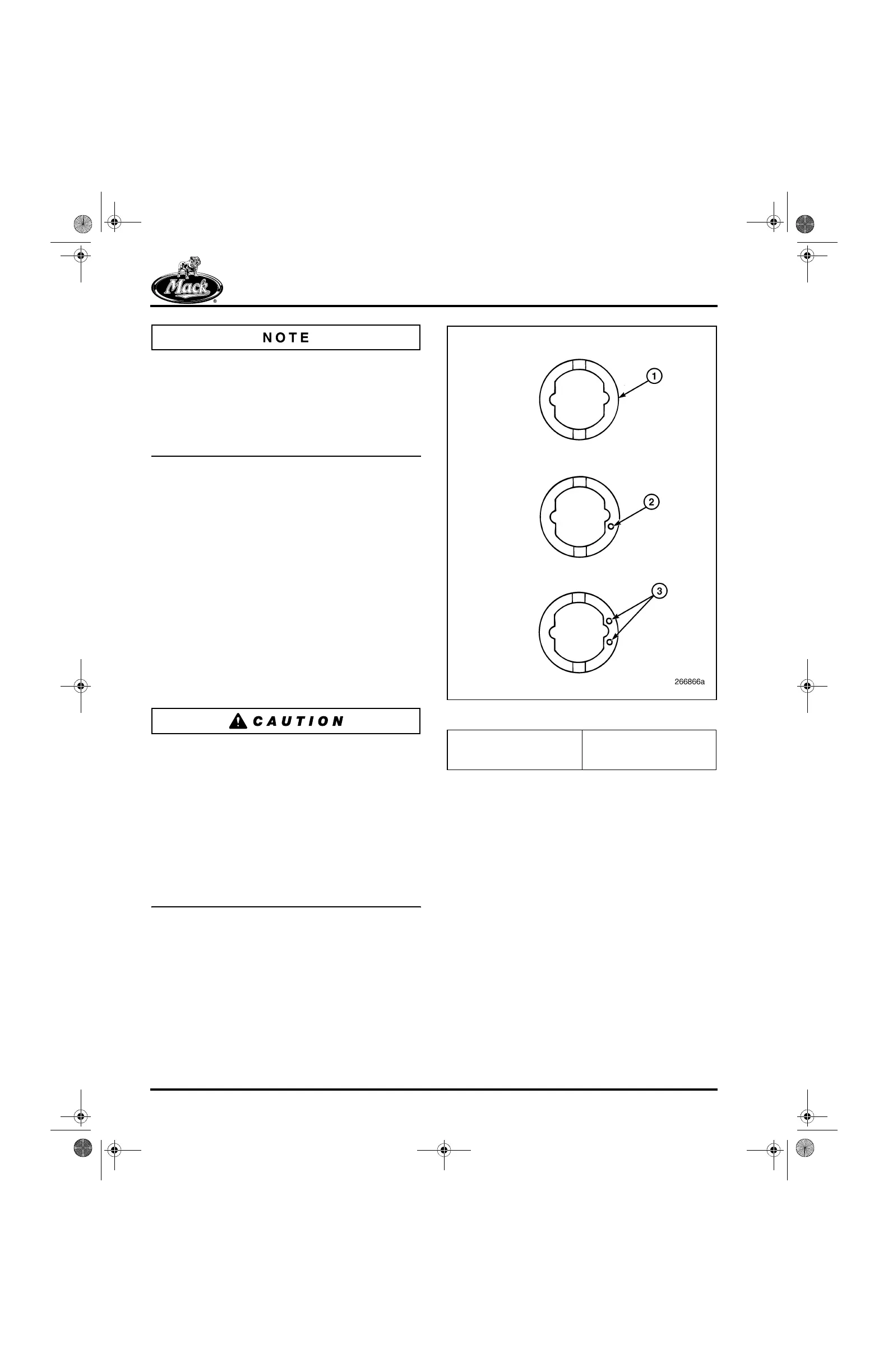

앫 Check the fit of a new “P2” H-ring

(+0.0015 inch [+0.0038 mm] oversize).

If it is a press-fit, install it. The P2 can

be identified by a single dot formed into

the bottom surface next to the flat as

shown in Figure 195.

앫 If the P2 is slip-fit, install a new “P3”

H-ring (+0.0030 inch [+0.076 mm]

oversize). The P3 can be identified by

two dots formed into the bottom

surface.

An oversized H-ring is to be used only when the

bore in the cylinder block is oversize. To use an

oversize H-ring in an undamaged standard size

bore will result in a press-fit that is too tight,

causing the H-ring to collapse. A collapsed H-ring

will eliminate free movement of the valve lifter or

prevent it from being installed. For a proper

press-fit, the H-ring-to-bore interference fit should

be within the range of 0.0006–0.0020 inch

(0.015–0.051 mm). An interference fit less than

the 0.0006-inch minimum will result in the H-ring

dislodging or turning in the block bore.

195

Figure 195 — Available H-RIng Sizes

3. If the lifter bore appears OK (will support the

interference fit of the H-ring), clean the bore

and dislodged H-ring (or new H-ring, if

required) with Loctite

®

Primer T. Then apply

Loctite

®

RC/609 to the bore and to the

H-ring outside surface.

4. Use service tool J 41683 to install the H-ring.

This tool pilots into two lifter bores at the

same time to properly align and install the

H-ring. If the proper interference fit has been

maintained, resistance should be felt as the

H-ring is driven into the bore. Refer to

Figure 196 and Figure 197.

1. Standard (No Dots)

2. 0.0015-Inch Oversize

(1 Dot)

3. 0.0030-Inch Oversize

(2 Dots)

5-111.bk Page 196 Monday, July 10, 2006 2:26 PM

Loading...

Loading...