Page 206

REPAIR INSTRUCTIONS, PART 1

1. Thoroughly clean and dry the prepared

cylinder block, counterbore ledge and

cylinder sleeves. Refer to the cylinder block

cleaning and inspection procedures in this

section.

2. If the counterbore ledge has been cut, place

the necessary shims on the cylinder block

counterbore ledge (sleeve seat). Always try

to use a single shim, if possible. If more than

one shim is necessary, always use the least

number of shims required to achieve the

proper cylinder sleeve flange height. Always

place the thickest shim on the bottom.

If shims are used, they must be placed on a

clean, dry cylinder block sleeve seat, with the

thickest shim on the bottom. Apply RTV silicone

on top of the shims only. If RTV is applied under

the shims, the shims may be displaced when the

sleeve is installed.

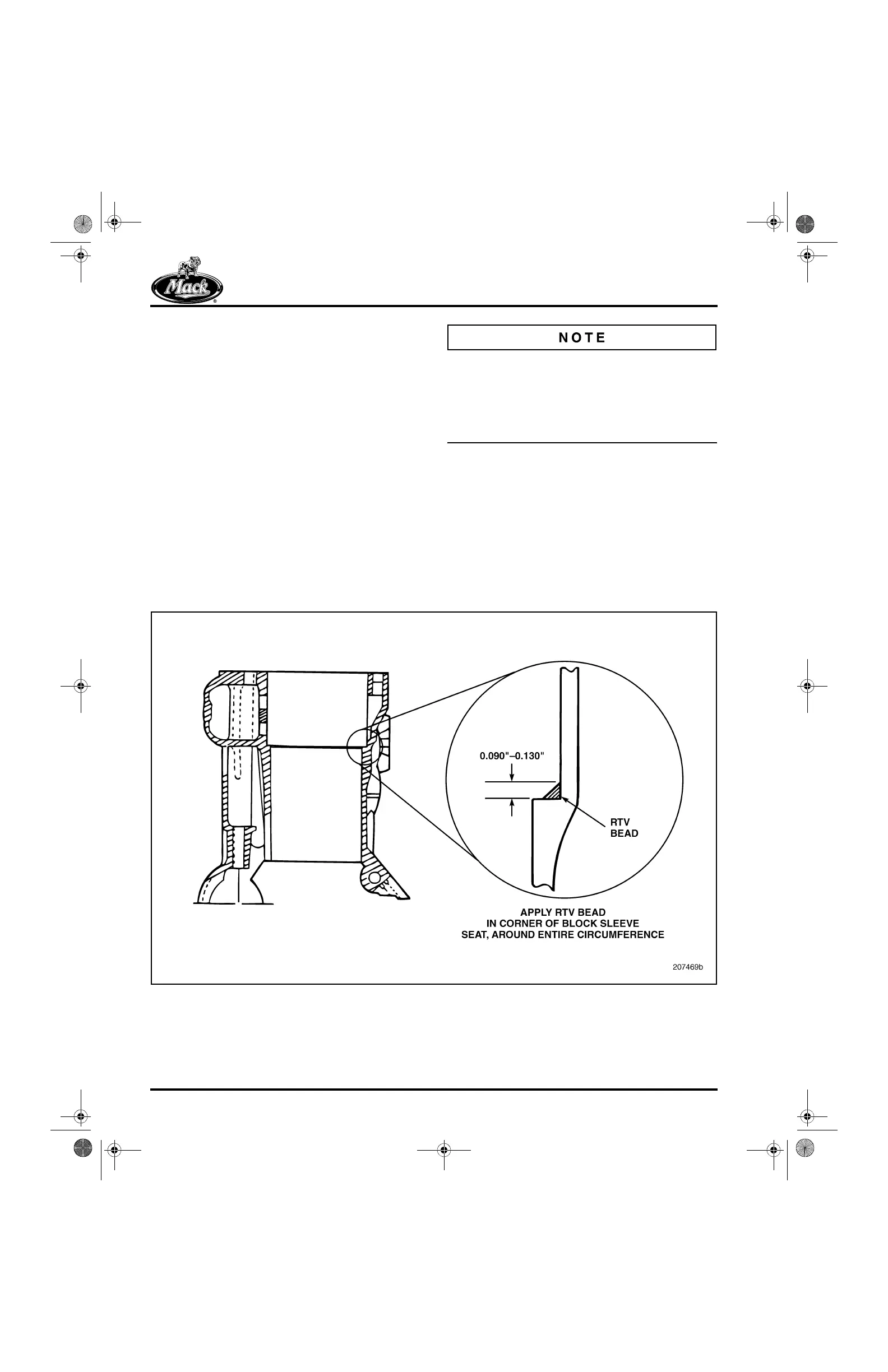

3. Apply approximately a 0.090–0.130-inch

(2.286–3.302 mm) bead of RTV silicone

(MACK Silastic

®

342SX32, Dow Corning

Silastic

®

RTV732, General Electric RTV130

or equivalent) in the corner of the cylinder

block sleeve seat and completely around the

cylinder wall as shown in Figure 210. Do not

use excessive amounts of RTV. Do not

apply the bead more than 0.130-inch

(3.302 mm) high.

210

Figure 210 — Cylinder Block Sleeve Seat

5-111.bk Page 206 Monday, July 10, 2006 2:26 PM

Loading...

Loading...