REPAIR INSTRUCTIONS, PART 2

Page 375

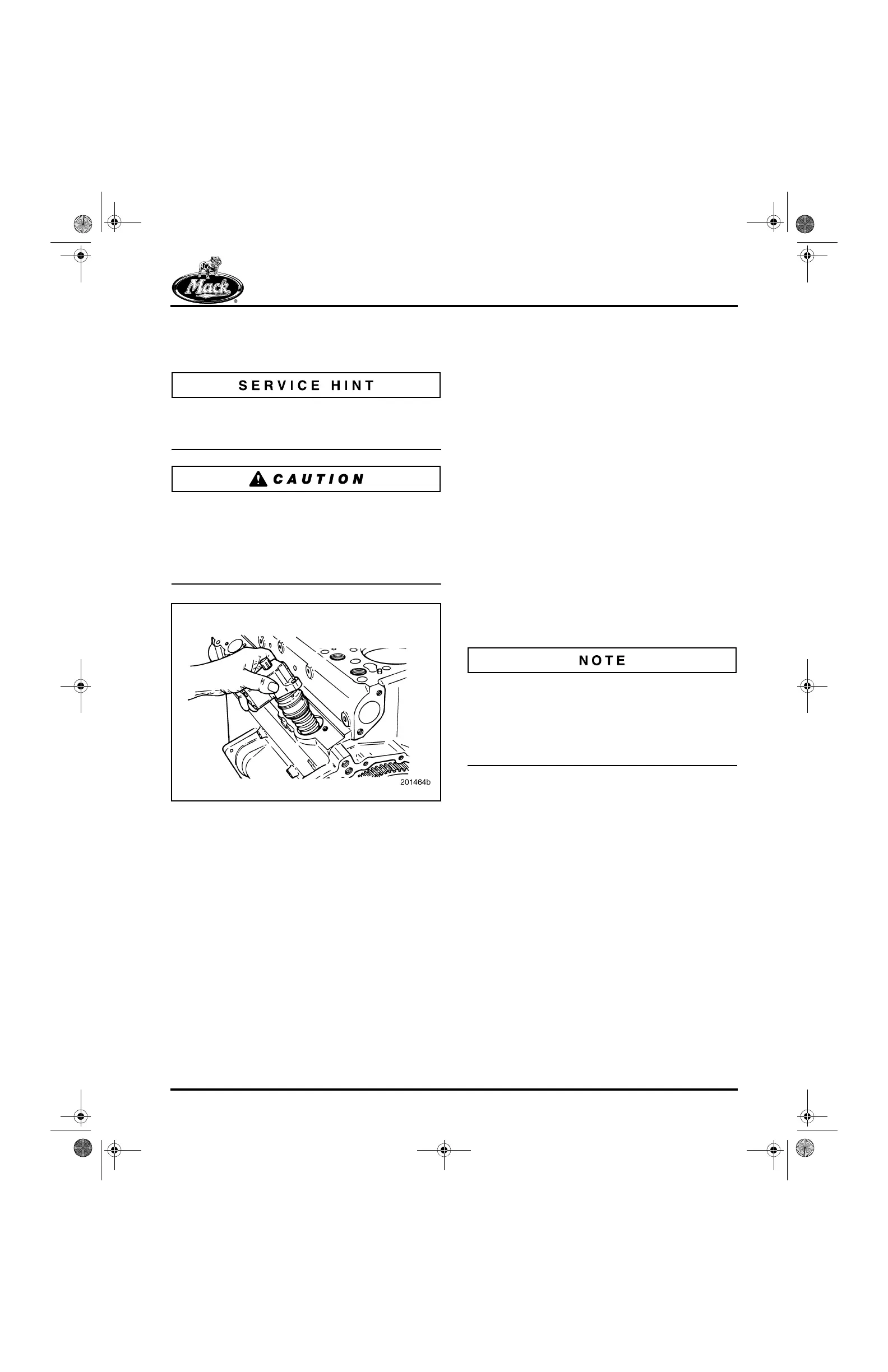

2. Generously lubricate EUP O-rings with clean

engine oil and install the EUP into the

cylinder block (Figure 449).

Minimize oil above the top O-ring to avoid

weepage of excess oil (trapped above the top

O-ring) onto the cylinder block.

To avoid O-ring damage, the cam lobe must be

positioned with the base circle UP prior to

installation of each EUP. Engine barring tool (tool

No. J 3857-A) MUST be used to rotate the

engine. DO NOT use the starter to rotate the

engine.

449

Figure 449 — Unit Pump Installation

3. If not previously done, inspect each EUP

hold-down bolt hole in the engine block for

rusty or damaged threads. Clean or tap

block bolt holes to remove rust or dirt as

required. Use an M10 x 1.5 bottom tap.

4. Install new EUP hold-down bolts and lightly

lubricate the threads and underside of the

bolt head with clean engine oil prior to

installation. Tighten bolts evenly to draw the

EUP into the cylinder block. Tighten the

screws to 60 lb-ft (81 N폷m).

5. Reinstall the injection line and torque to

specification as follows:

앫 Line nut at cylinder head: 35 lb-ft

(47 N폷m)

앫 Line nut at EUP: 25 lb-ft (34 N폷m)

6. Reinstall the harness wire connections at

the EUP terminals and tighten to

specification, 13 lb-in ± 2 lb-in

(1.5 ± 0.2 N폷m). Do not bend the wire

terminals down after installation.

If an EUP has been replaced with a new or

remanufactured unit, the replacement unit must

be calibrated as described under “Electronic

Pump Calibration” in the ENGINE SETUP AND

ADJUSTMENTS section. This will ensure

optimum engine performance.

7. Reinstall both the EGR hot and cool tubes

(AC engine only).

8. Reinstall the heat shields.

5-111.bk Page 375 Monday, July 10, 2006 2:26 PM

Loading...

Loading...