Page 414

REPAIR INSTRUCTIONS, PART 2

503

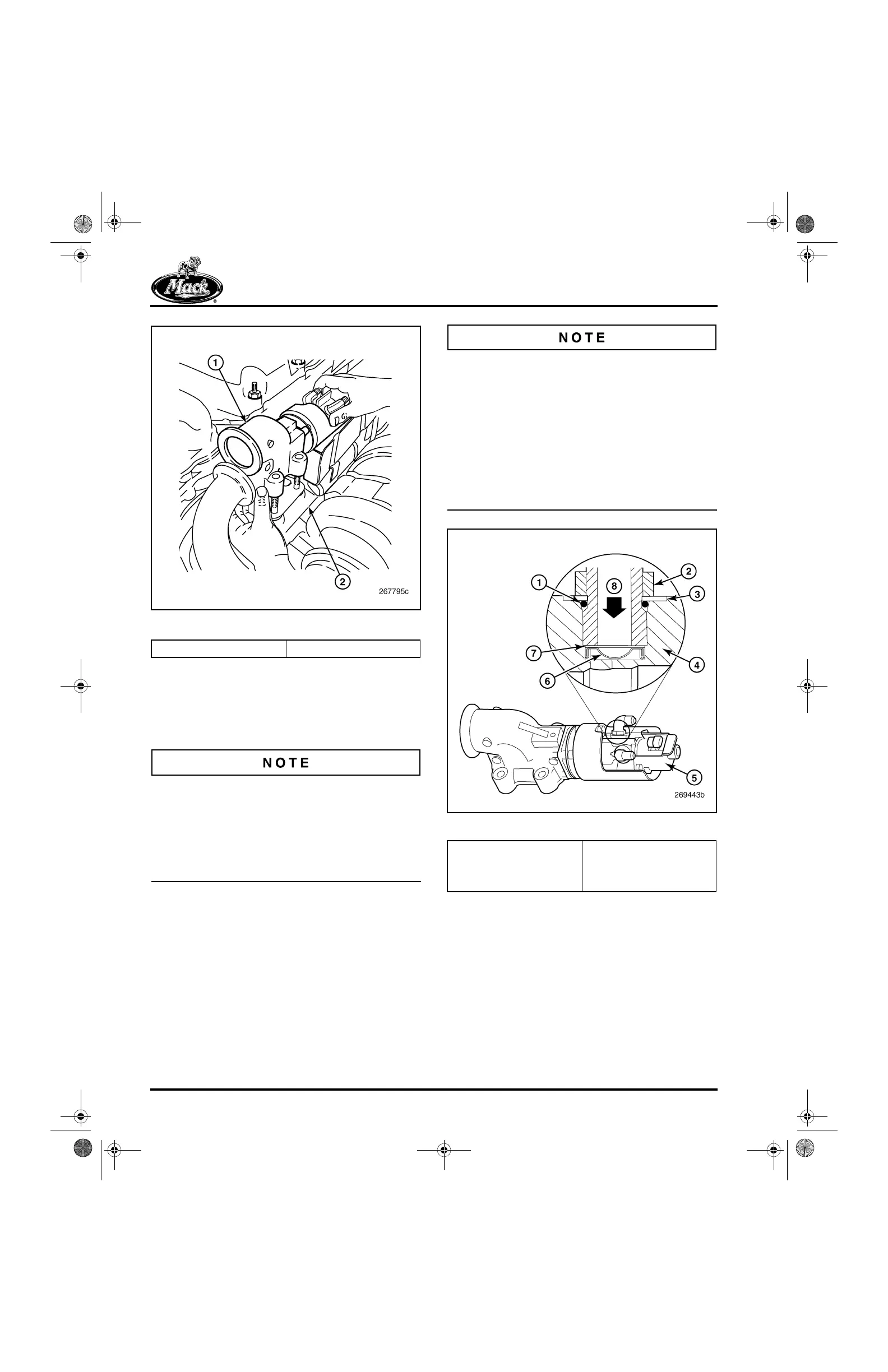

Figure 503 — EGR Valve Installation

5. Install a new wire-mesh seal in the flange of

the gas hot tube. Place the tube in position

on the valve gas outlet flange, install a new

clamp and tighten to specification, 110 lb-in

(12.4 N폷m).

EGR gas tube clamps can be reused if there is no

damage and the threads are not corroded.

However, with damaged or corroded threads, the

clamps cannot be tightened to the proper torque

specification for a gas-tight seal. Clamps used on

the hot-side tube are prone to corrosion and

damage and should be replaced.

6. Lightly tap the clamp with a light rubber

mallet and then retighten it to specification.

7. Tighten the EGR valve retaining nuts to

specification, 40 lb-ft (55 N폷m).

8. Reconnect the oil supply line to the external

oil manifold and tighten to specification.

9. Connect the oil supply and oil return lines to

the valve assembly (Figure 505).

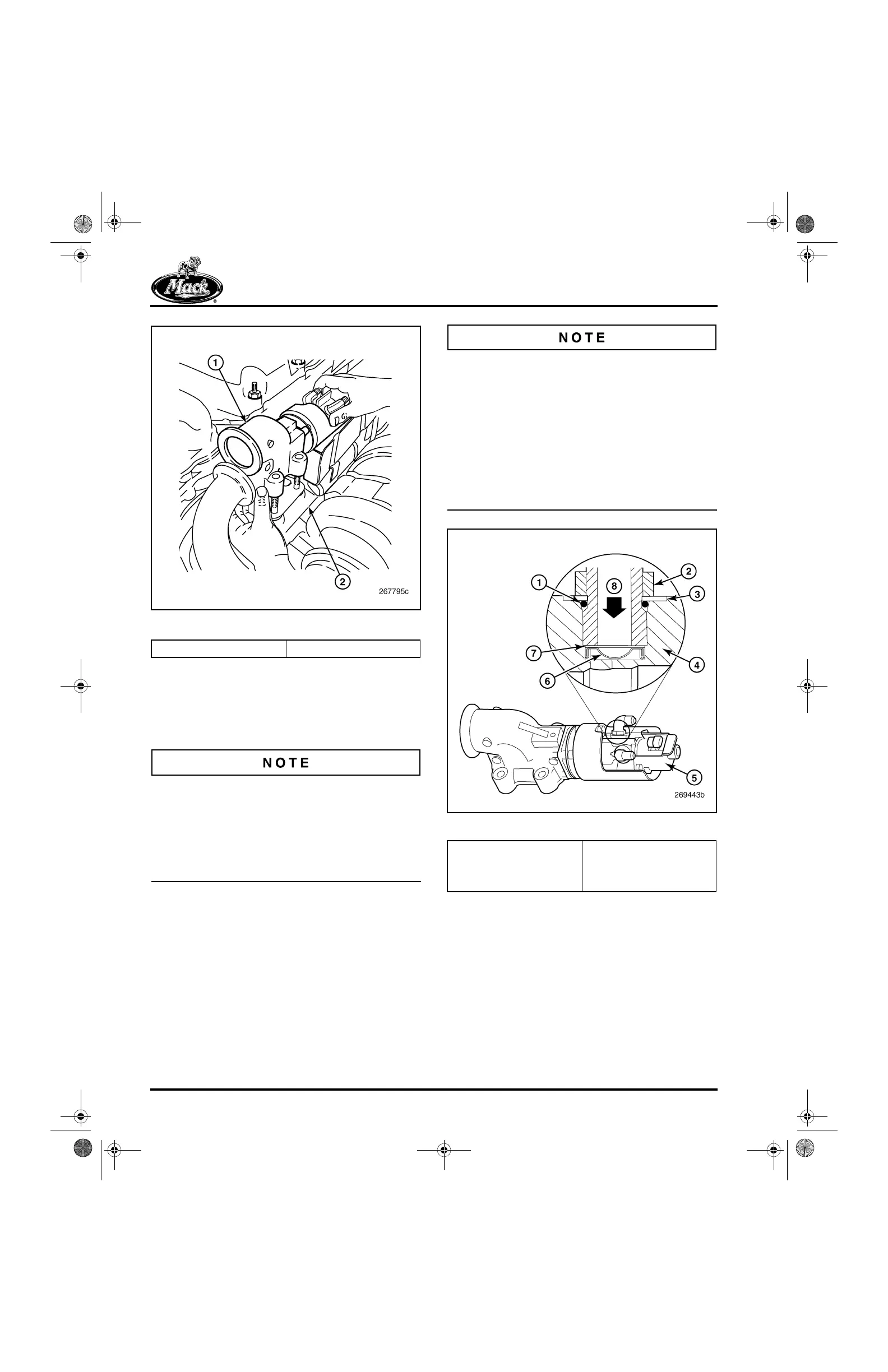

Beginning with March 2004 production, a filter

screen has been added to the oil inlet port on the

EGR valve. It is retained in place by a wave

washer and inlet hose fitting (Figure 504). Valves

fitted with the filter screen are identified by a

green dot (interim identification) on the valve

body or by the new part number, 691GC514C, on

the sheet metal cover. When connecting the oil

line to the EGR valve, make sure that the screen

and wave washer are in place and secured by the

hose fitting.

504

Figure 504 — EGR Valve Oil Inlet Filter Screen

10. Connect the electrical lead to the terminal on

the valve assembly.

1. EGR Valve Assembly 2. Exhaust Manifold

1. O-Ring

2. Fitting Jam Nut

3. Integral Washer

4. Valve Body

5. Part Number Location

6. Filter Screen

7. Wave Washer

8. Oil Flow Direction

5-111.bk Page 414 Monday, July 10, 2006 2:26 PM

Loading...

Loading...