DESCRIPTION AND OPERATION

Page 75

87

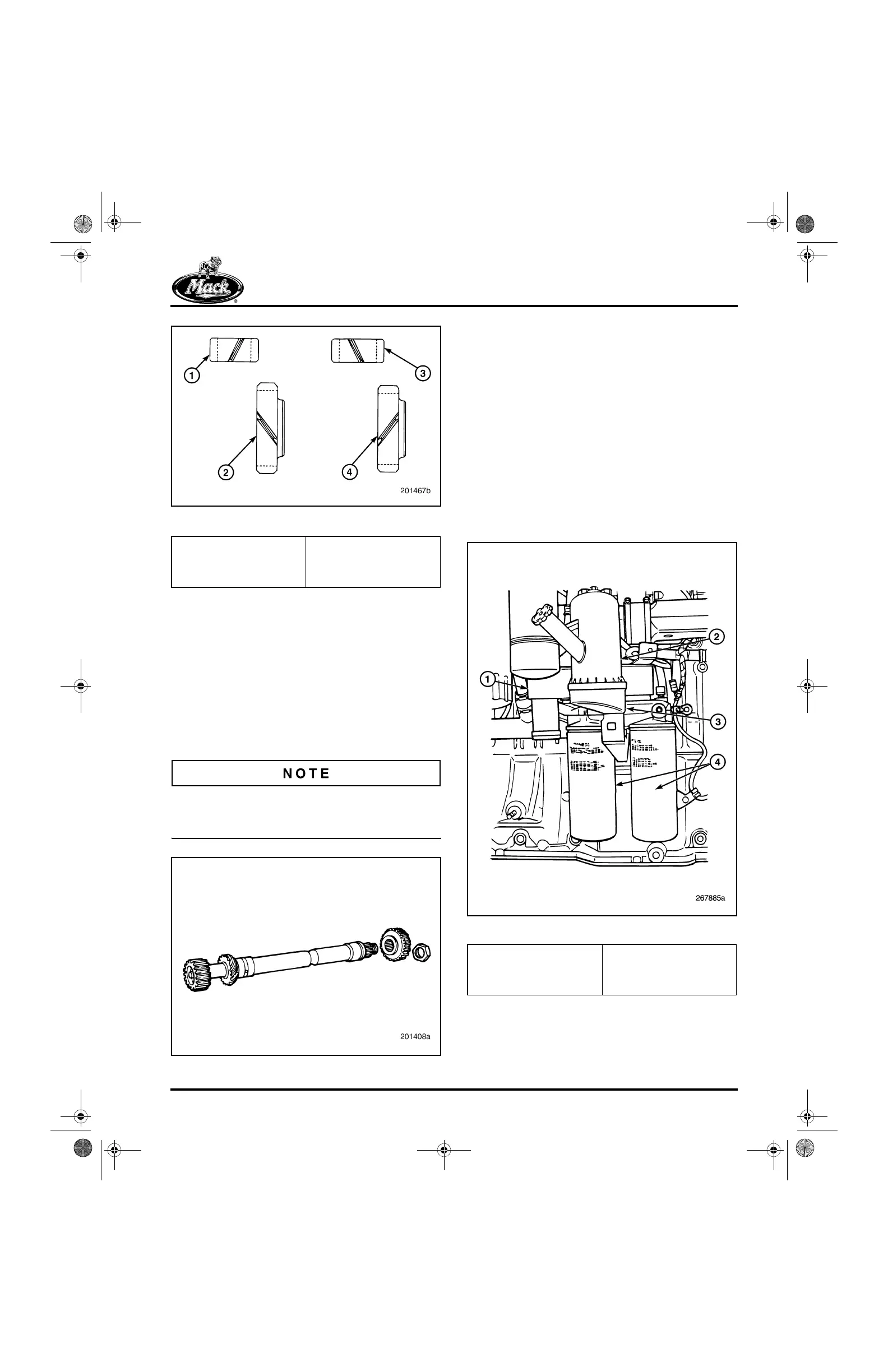

Figure 87 — Oil Pump Drive Gears

The ASET™ oil pump also differs from the E7 oil

pump in that it is designed to accommodate the

faster auxiliary shaft speed. In addition, the

auxiliary shaft used on the ASET™ engines

(Figure 88) is through-drilled to carry oil to the

rear auxiliary shaft bushing. This is different from

the E7 engine, which provides oil to the rear

bushing through a cylinder block oil passage. An

E7 shaft CANNOT be used in an ASET™ engine.

Doing so will result in failure of the auxiliary shaft

rear bushing and the air compressor.

The ASET™ auxiliary shaft is identified by three

machined circumferential cuts in front of the

stamped part number.

88

Figure 88 — Auxiliary Shaft

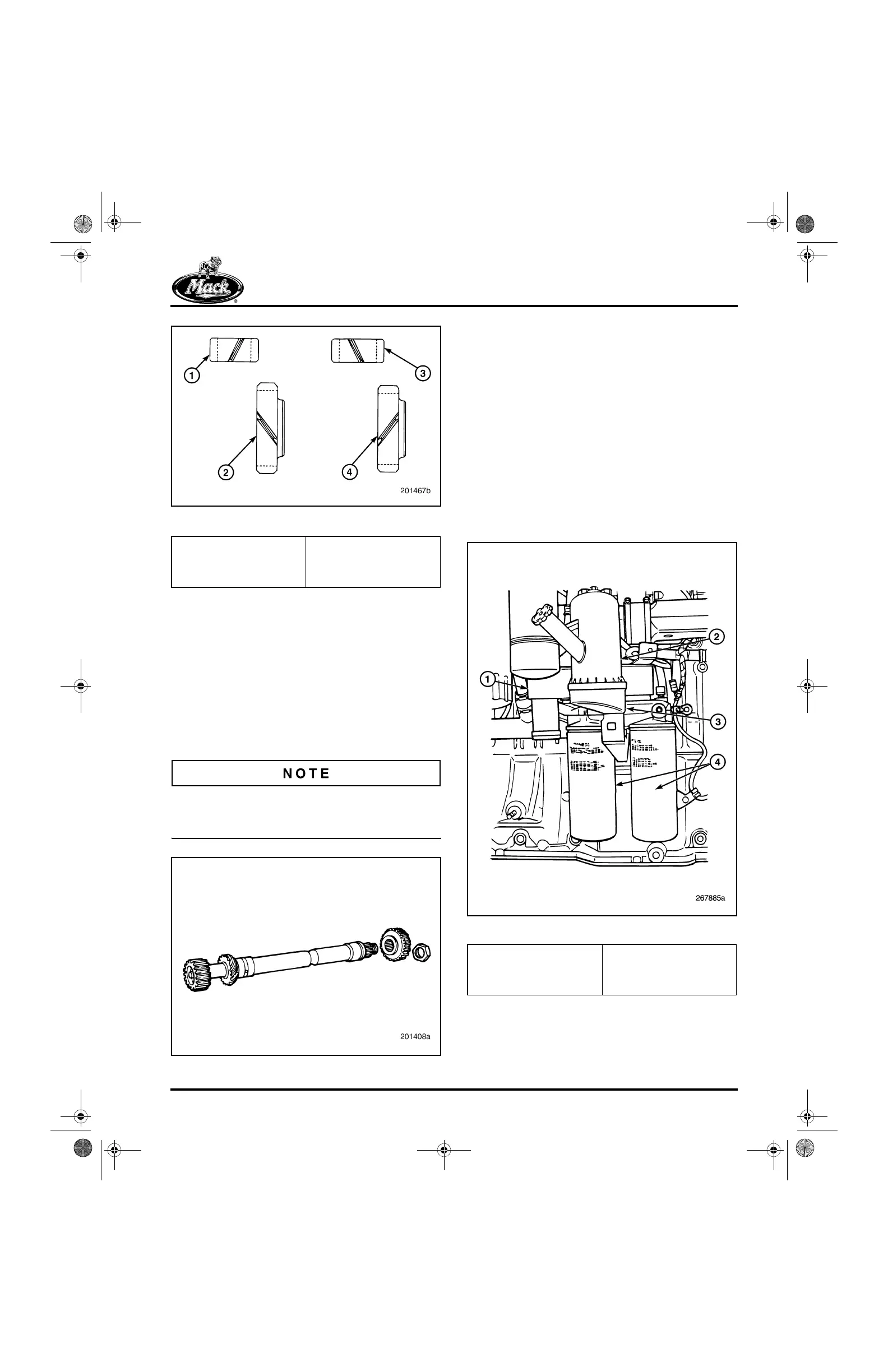

OIL COOLER AND FILTER MOUNTING

BRACKET

The engines are equipped with a plate-type oil

cooler and a centrifugal oil filter assembly, called

Centri-Max

®

ULTRA or ULTRA PLUS, that is

inverted and mounted on top of the bracket. With

this arrangement, the filter housing includes the

oil fill port.

The main member to which the oil cooler and oil

filters are mounted is a one-piece aluminum

casting which bolts to the four-bolt pad on the

cylinder block. An oil drain passage within the

casting allows the oil from the centrifugal filter to

drain back to the crankcase.

89

Figure 89 — Oil Cooler/Filter Mounting Bracket

1. E7 Oil Pump Gear (12

Teeth)

2. E7 Aux. Pump Gear (18

Teeth)

3. ASET™ Oil Pump Gear

(13 Teeth)

4. ASET™ Aux. Shaft Gear

(17 Teeth)

1. Oil Cooler

2. Centri-Max

®

ULTRA or

ULTRA PLUS Oil Filter

3. Oil Filter Mounting

Bracket

4. Spin-On, Full-Flow Oil

Filters

5-111.bk Page 75 Monday, July 10, 2006 2:26 PM

Loading...

Loading...