M A E D A Mini-Crawler Crane Section 4 –

TRAILERING

1/2019 MC285C-3 4-141

Ramp Planks

NOTICE: Ramp planks must be of adequate

length (wider than the rubber tracks) and not

exceed 15 degrees, when loading the machine.

• Ramp planks must be of adequate thickness

and strength to withstand the weight and mass

of the machine.

• Place ramp planks perpendicular to the truck

box.

• Match the centre of each rubber track with the

centre of the corresponding ramp plank.

Misaligned ramp planks may cause the machine

to slip off the ramp planks and cause machine

damage.

• Reinforce with blocks or other support if the

ramp planks deflect.

• Remove mud and other substances from the

footing to prevent the machine from skidding

over the ramp planks. Remove substances

stuck to the ramp planks such as grease, oil or

ice, and keep clean. Be especially careful during

rain to avoid slipping.

• Never change direction on the ramp planks.

Move completely off the ramp planks before

changing direction.

Loading / Unloading Procedure

WARNING! Overturn Hazard. Always load the

machine moving backward onto the trailer.

Moving forward onto the trailer could result in

an unstable condition.

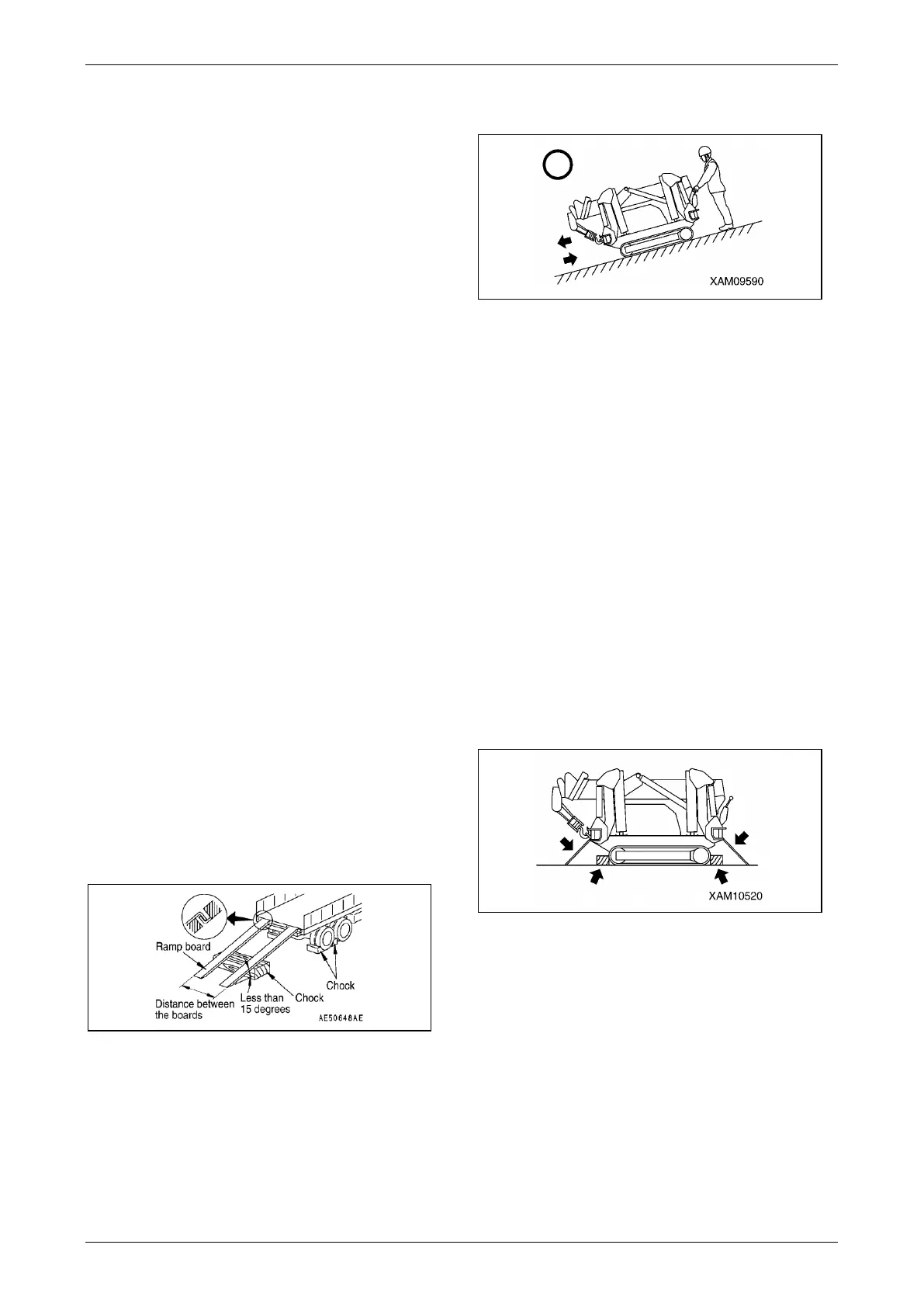

1. Place wheel blocks under the wheels of the

trailer to secure the trailer.

Fig. 4-378

2. Secure the ramp planks to the trailer and

align the machine with the ramp planks and

trailer.

3. Verify the two ramp planks are at the same

height.

4. Move the accelerator lever to keep the engine

at low speed.

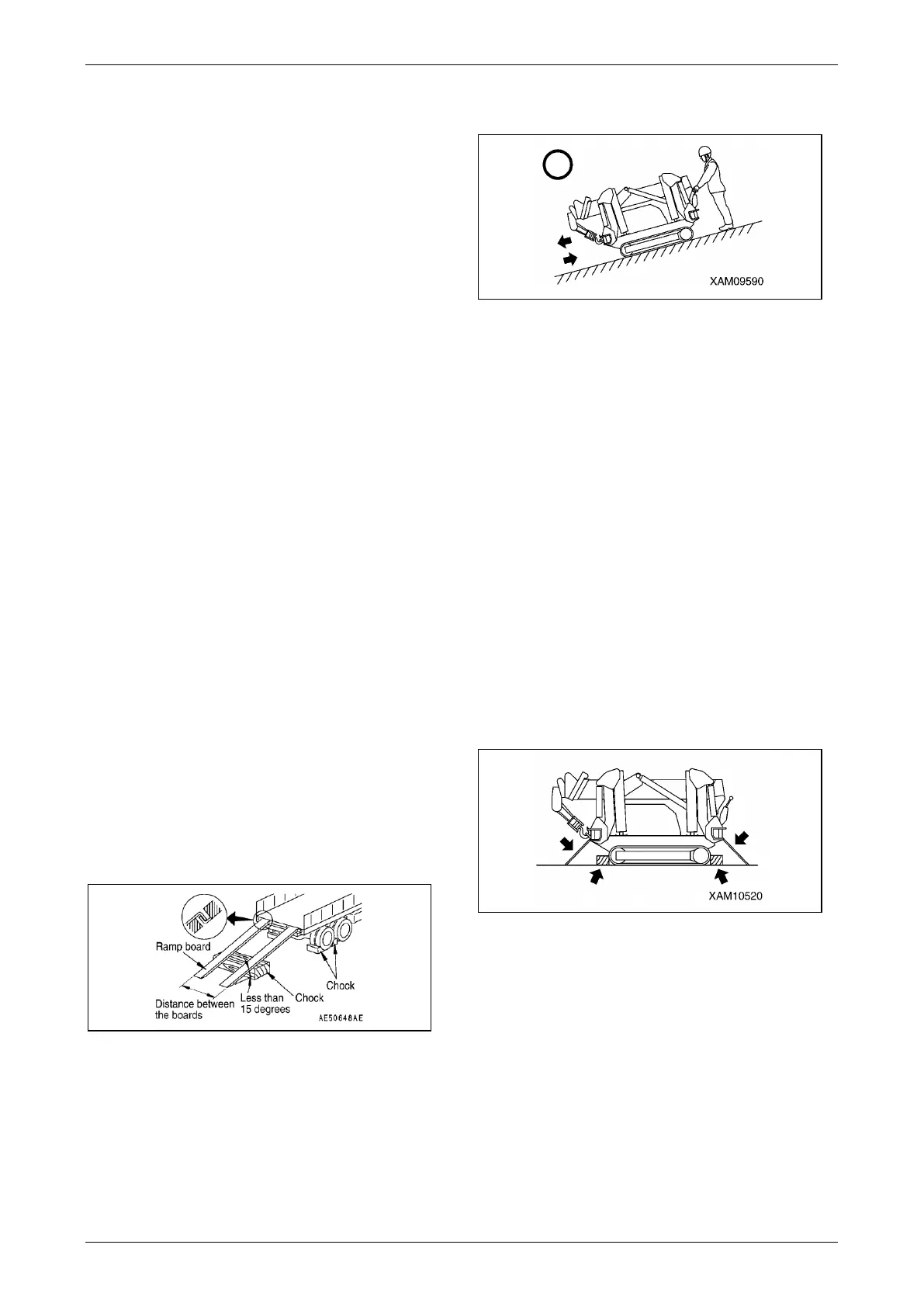

Fig. 4-379

5. Travel slowly toward the ramp planks, and

load/unload the machine while keeping the

boom from hitting the trailer. WARNING!

Sudden Movement Hazard. Only move the

travelling levers while loading or unloading

the machine. Moving other levers could result

in unaccepted sudden movement of the

machine.

6. Load the machine to the desired position on

the trailer.

7. Stop the engine and remove the key from the

Starter Switch.

8. Install a square timber block in front and back

of the rubber tracks to prevent the machine

from moving during transportation. Secure

the machine, using the four tie-down points,

with chain or wire rope to prevent movement

or slipping.

Fig. 4-380

Loading...

Loading...