M A E D A Mini-Crawler Crane Section 5 – AUXILIARY WINCH PERIODIC MAINTENANCE

1/2019 MC285C-3 5-83

AUXILIARY WINCH PERIODIC MAINTENANCE

Periodic Maintenance Schedule

Replace oil in winch reduction

gearcase

Check oil level and refill oil in

winch reduction gearcase

Periodic Maintenance Procedures

Before performing any of the maintenance or

inspection procedures, read “GENERAL

MAINTENANCE INFORMATION AND

PRECAUTIONS” on page 5-2.

After Initial 10 Hours of Operation

The following maintenance should be performed

after the first 10 hours of operation.

• Grease Machine Units - See “Grease Machine

Units” on page 5-83.

Maintenance Every 50 Hours

Grease Machine Units

CAUTION:

• Grease type varies with greasing points.

Failure to grease properly may cause the

machine to shorten its useful life. See the

following table for grease types.

• Greasing a new machine is required once

every 10 hours until the machine attains the

first 100 hours of operation that initial fit

emerges.

• Use proper grease specified below according to

the greasing points.

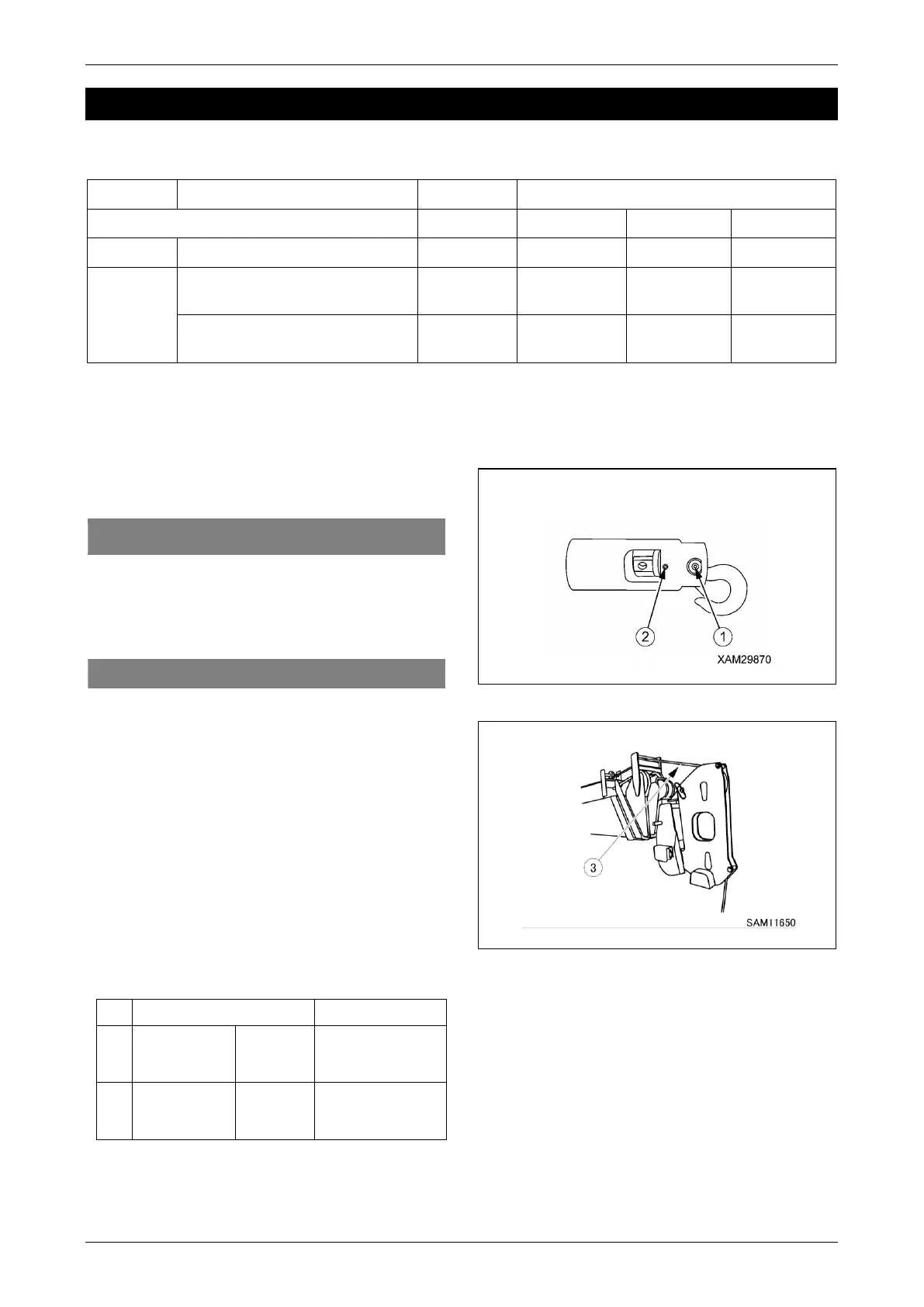

Greasing of

the hook

block

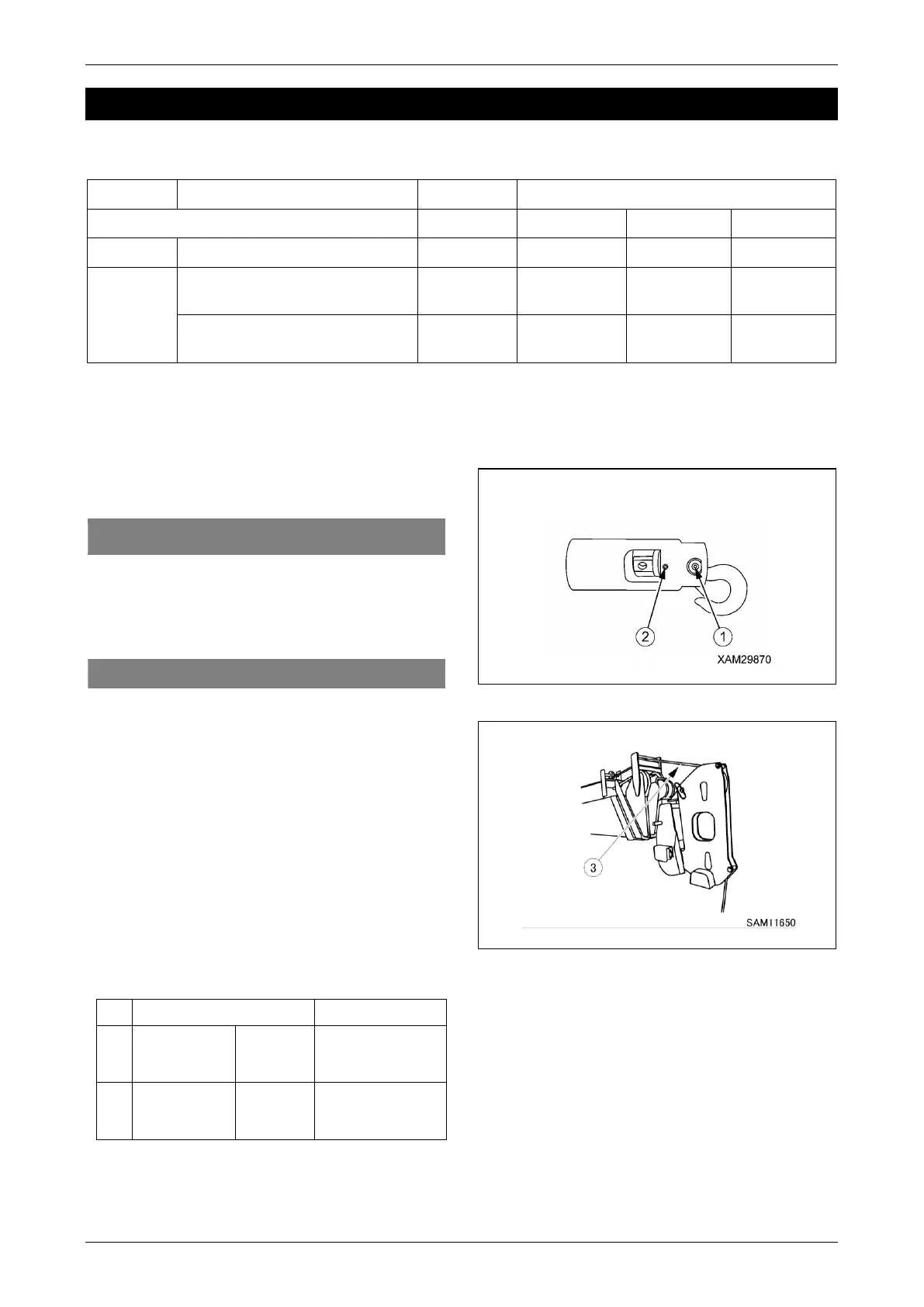

Greasing of

the winch

wire rope

1. With the use of the grease gun, grease the

grease plugs.

2. Wipe off old grease squeezed out after

greasing.

3. Apply wire rope grease to prevent wear and

rust of the wire rope. Before applying, remove

dirt from the rope surface.

Fig. 5-174

Fig. 5-175

Loading...

Loading...