M A E D A Mini-Crawler Crane Section 5 – GENERAL MACHINE MAINTENANCE

1/2019 MC285C-3 5-61

Checking Rubber Track Tension

Rubber tracks wear differently depending on

working conditions and soil quality. Periodically

check for wear and measure tension of the rubber

tracks.

On a new machine or when new parts are

installed, initial slack occurs between 5 and 30

hours of operation. Inspect and adjust the tension

frequently during the initial slack period to prevent

the rubber track from falling off due to insufficient

tension.

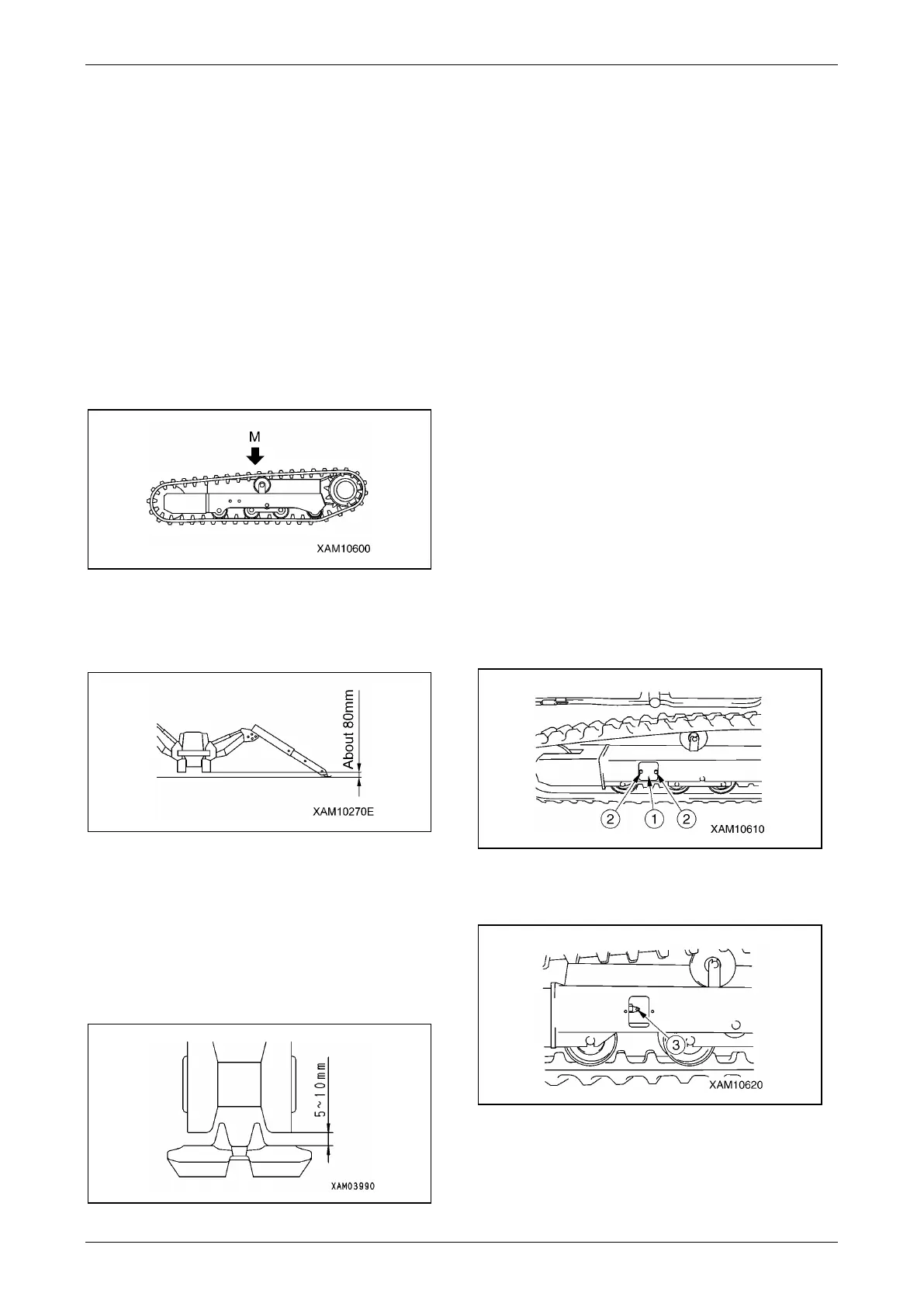

1. Move the left and right crawlers so the

connection of the rubber track (M) comes to

the top centre between the axles.

Fig. 5-127

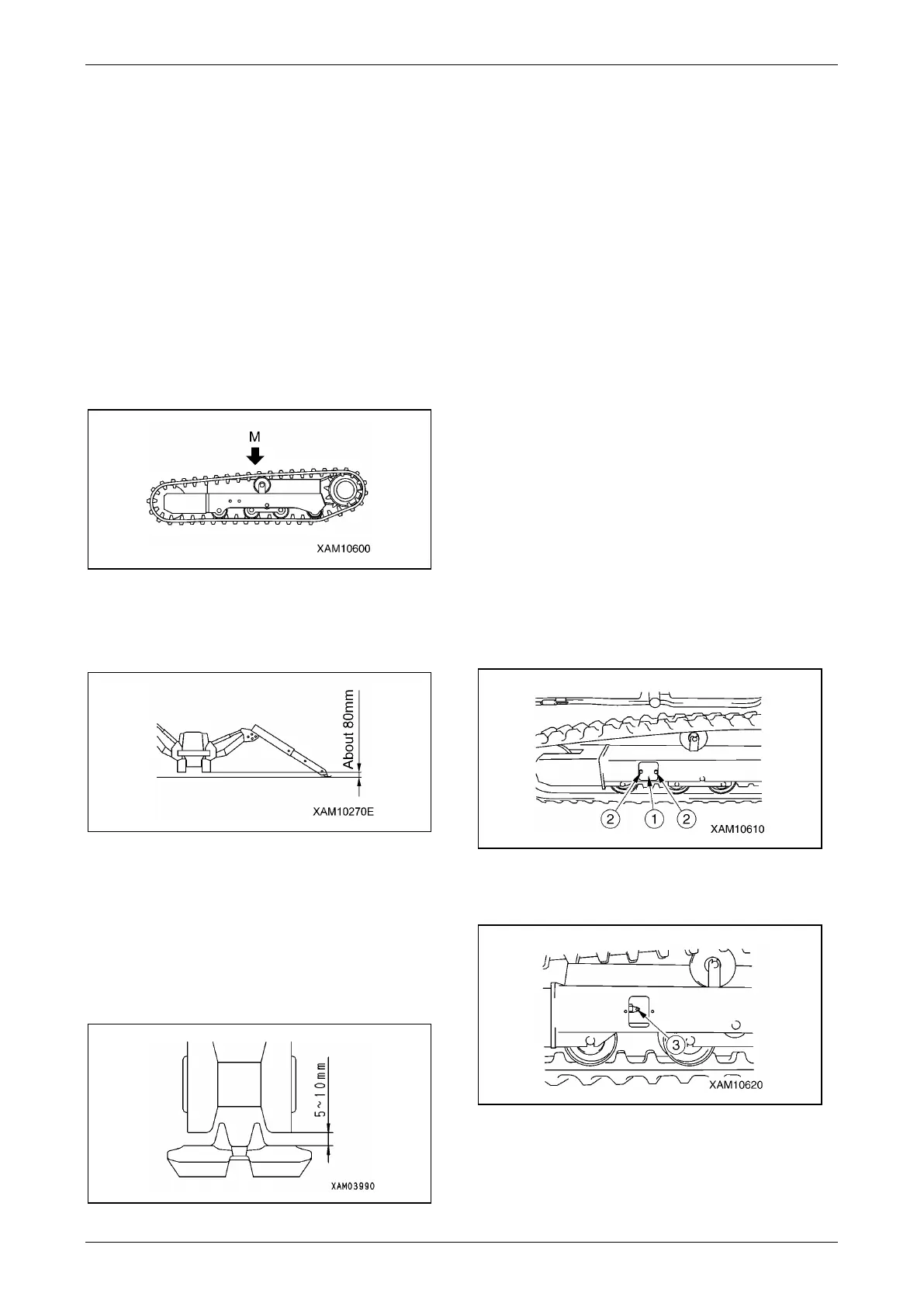

2. Set the outriggers and raise the tracks

approximately 80 mm from the ground. See

“OUTRIGGER SETTING” on page 4-38.

Fig. 5-128

3. Measure the clearance between the centre of

the track roller wheel tread and the shoulder

of the rubber track.

4. Standard tension of the rubber track is 5 to

10 mm clearance between the wheel tread of

the centre of the track roller and the shoulder

of the rubber track.

Fig. 5-129

5. If the tension is not within specification, see

“Adjusting Rubber Track Tension” on page

5-61.

Adjusting Rubber Track Tension

WARNING! Exposure Hazard. The rubber track

tension adjuster contains grease under high

pressure.

Use the following guidelines when adjusting track

tension.

• Do not turn the grease valve more than one full

turn out.

• Stand to the side of the adjuster when adjusting

tension.

• Check the tension of the rubber track before

adjusting. See “Checking Rubber Track Tension”

on page 5-61.

In case the tension is too low (to increase

tension)

If the rubber track tension is too low (15 mm or

more), the track could fall off during operation and

cause premature wear of the metal core. Perform

the following adjustments.

6. With two mounting bolts (2) removed, take off

the inspection cover (1).

Fig. 5-130

7. Pack the grease through grease valve (3) by

means of grease gun.

Fig. 5-131

Loading...

Loading...