Section 5 – INSPECTION

Mini-Crawler Crane M A E D A

5-24 1/2019 MC285C-3

Check / Add Slewing Motor Reduction

Gearcase Oil

Before checking or adding slewing motor

reduction gearcase oil, read the maintenance

precautions in “Handling and Service of Gearcase

Oil” on page 5-6.

1. Stop the machine on a level location.

2. See “Removing Machinery Cover” on page

5-14 and remove the machinery cover.

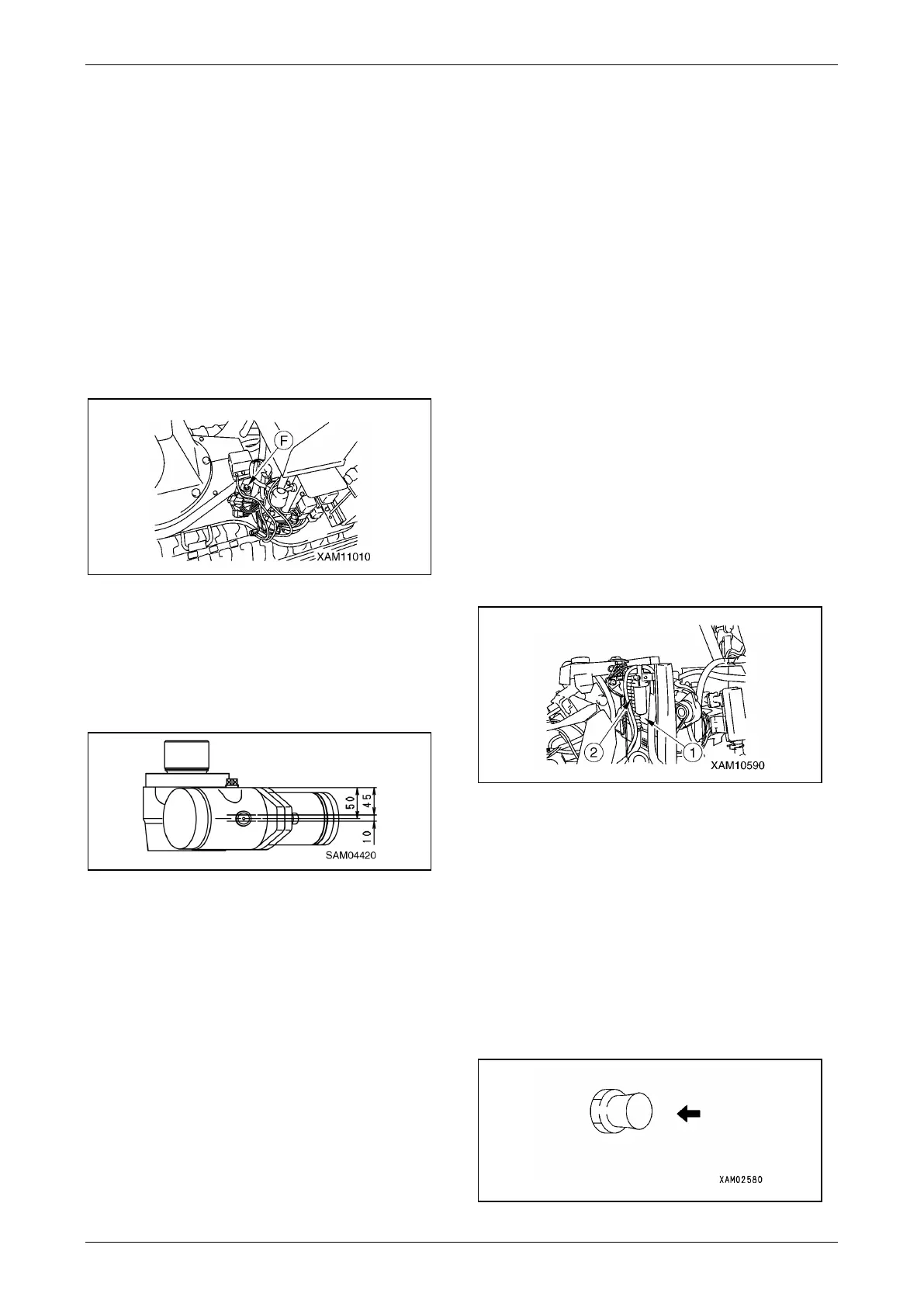

3. Remove the filler port plug (F) from the

slewing reduction gearcase. Fill with gear oil

from the plug hole up to the middle of the

gearcase.

Fig. 5-25

NOTICE: The height at middle of gearcase is

50 mm from the top of the filler plug. 50 mm

(±5 mm) is the appropriate oil level.

Do not allow ingress of dust or dirt when

measuring or filling oil.

Fig. 5-26

4. If the oil level is low, refill with the gear oil

from the plug hole of the filler plug.

5. After adding oil, install the filler plug and

securely tighten.

6. See “Installing Machinery Cover” on page

5-14 and install the machinery cover.

Check / Clean Radiator and Oil Cooler

Fins

WARNING! Exposure Hazard. Always wear

appropriate eye protection to prevent the risk

of eye injury when using compressed air.

NOTICE: Avoid damaging cooling fins with

compressed air. Use air pressure between 0.20

and 0.29 MPa (2 – 3 kg/cm

2

) and direct it away

from the fins. Damaged fins will cause water

leakage or overheating.

Check and clean cooling fins every day as

frequently as required, especially in dusty

environments.

1. Stop the machine on a level location.

2. Rotate and set the outriggers outward to

stabilise the machine. See “OUTRIGGER

SETTING” on page 4-38.

3. See “Removing Machinery Cover” on page

5-14 and remove the machinery cover.

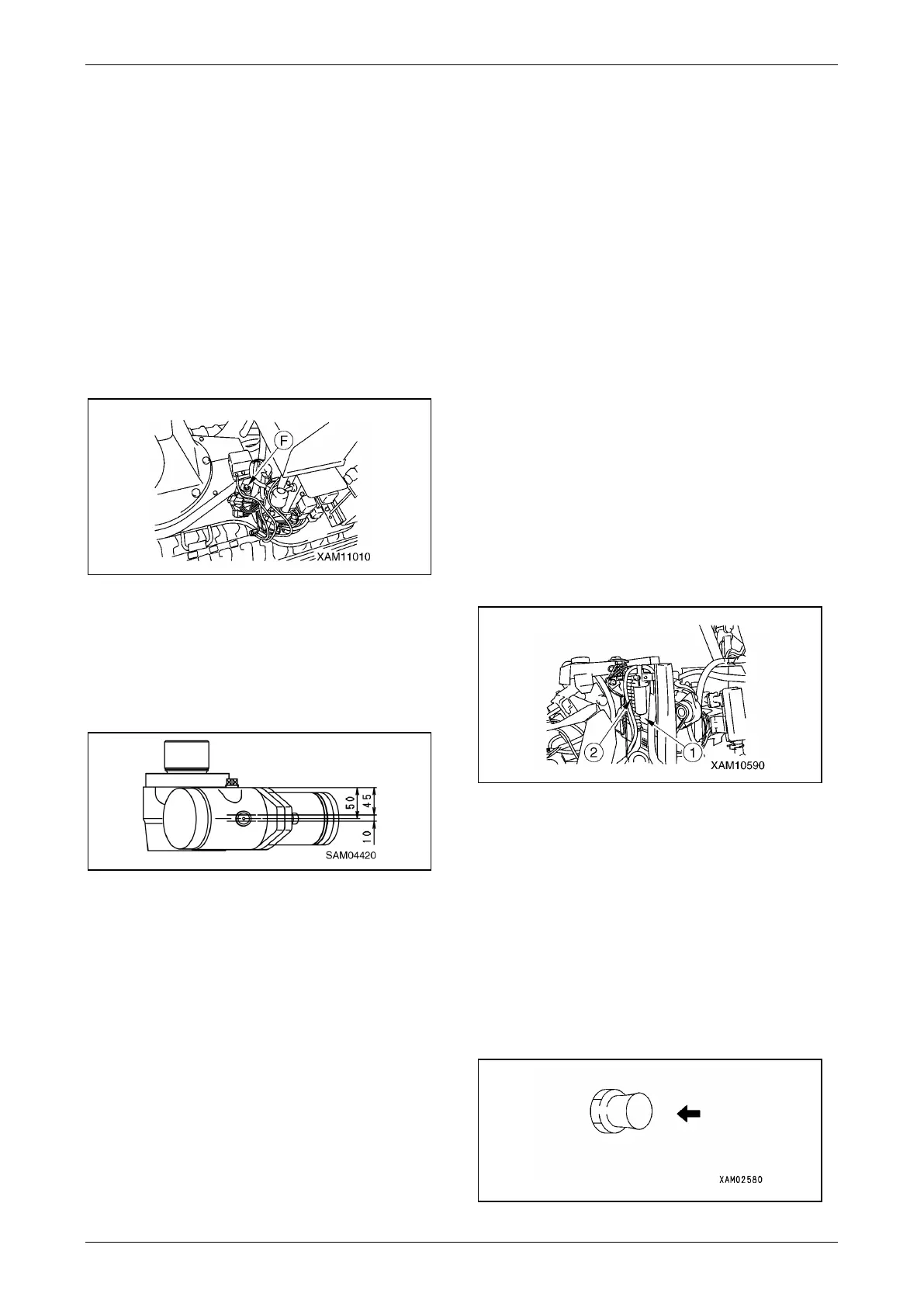

4. Use compressed air (0.20 to 0.29 MPa {2 to

3 kg/cm²}) to clean the oil cooler (1) and

radiator (2) fins.

Fig. 5-27

5. See “Installing Machinery Cover” on page

5-14 and install the machinery cover.

6. Rotate the outriggers inward and stow. See

“OUTRIGGER STOWING” on page 4-48.

Check Horn

1. Turn the Starter Switch to the ON position.

2. Press the Horn Switch to verify the horn

sounds. If the horn does not sound, the horn

may be faulty or the circuit may be open.

Repair or replace the horn.

Fig. 5-28

Loading...

Loading...