Section 5 – AUXILIARY WINCH PERIODIC MAINTENANCE

Mini-Crawler Crane M A E D A

5-84 1/2019 MC285C-3

Maintenance Every 100 Hours

Check Oil Level and Refill Oil in Winch

Reduction Gearcase

WARNING!

• Oil is extremely hot immediately after

operation of engine. Wait until oil cools

down before removing inspection port plug

after operation.

• For inspection and replenishment of oil, be

sure to stop engine.

CAUTION:

• Be sure to use oil specified in

“LUBRICATING OIL” on page 5-10 Failure to

use proper oil may cause the engine life to

shorten. Always use the specified oil for

replenishment.

• After the inspection and replenishment of oil,

prevent leakage from the threaded part of oil

inspection plug with sealer tape and

securely tighten it.

・ Plug removal Allen key: 8mm

1. Place the machine on a level surface.

2. See “OUTRIGGER SETTING” on page 4-38

to rotate the rotary of the “outrigger [4]”

outward.

3. Rotate the winch slowly until the oil inspection

plug (G) reaches a point where it can be seen

through the post side inspection hole (A).

Fig. 5-176

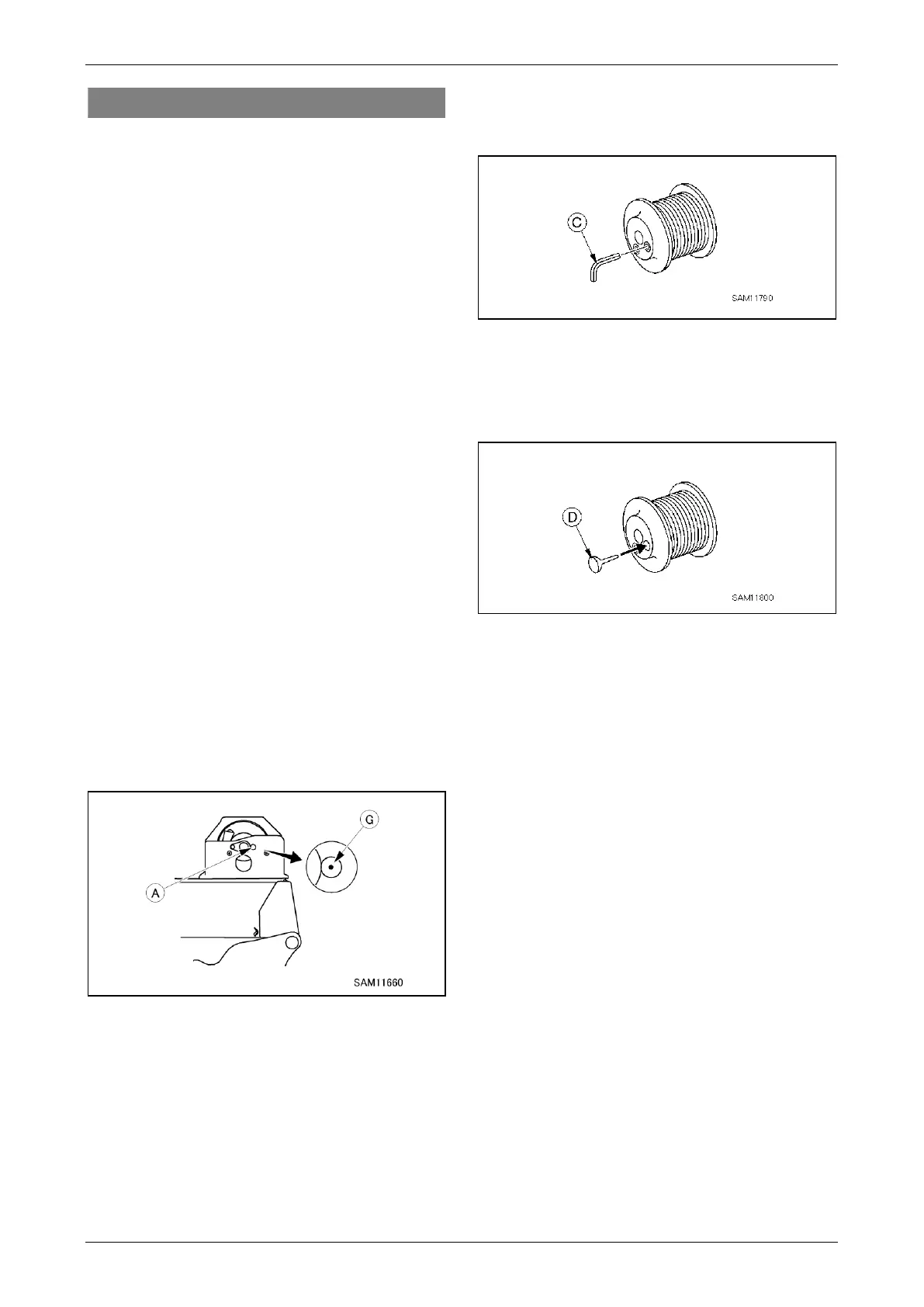

4. Use the hexagonal wrench (C) to loosen the

oil inspection plug. Check if the gear oil

exudes from the oil inspection plug.

Fig. 5-177

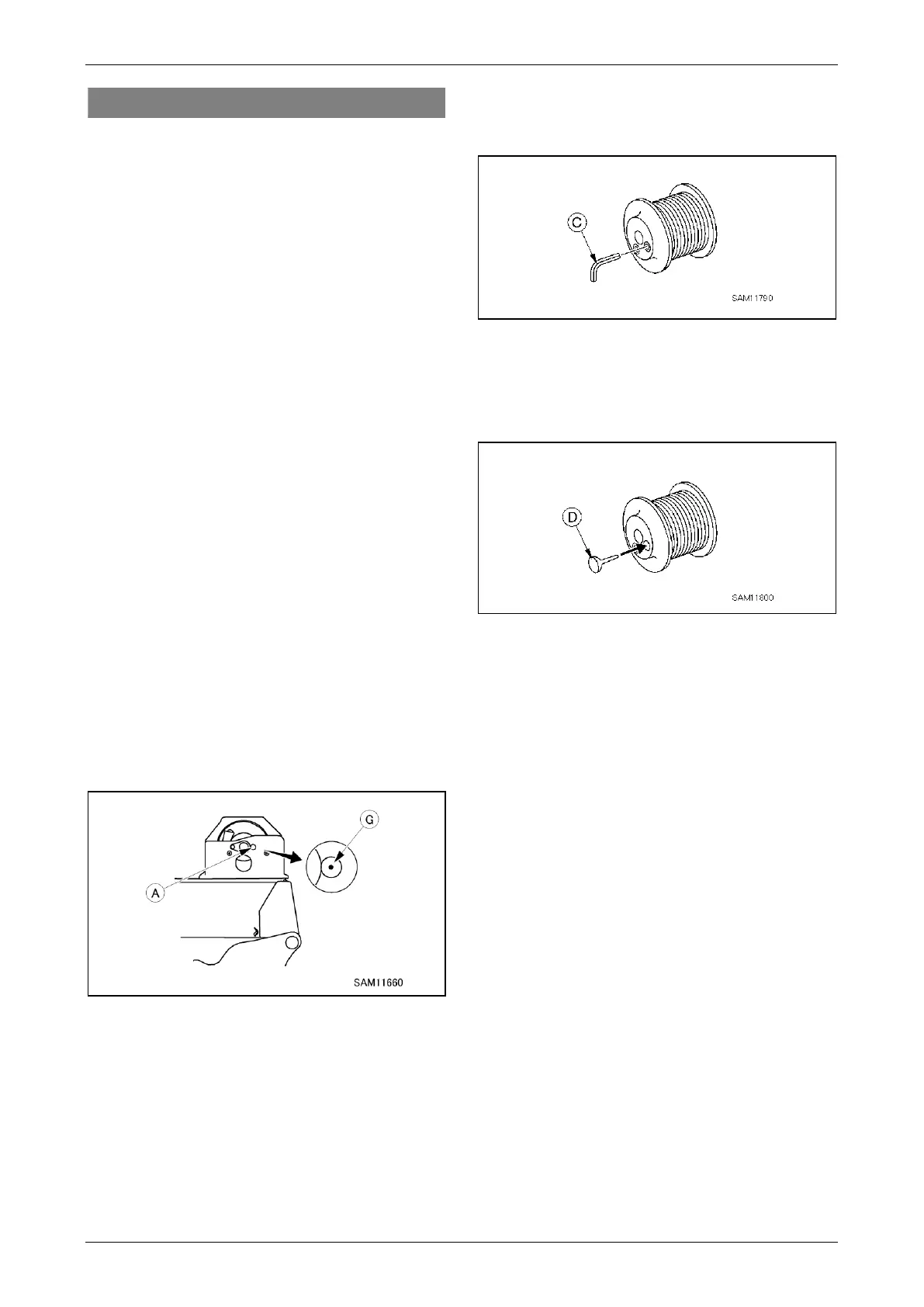

5. If no exudation of the gear oil is found, rotate

the oil inspection plug slowly to remove it.

Replenish gear oil with the use of an oil pump

(D).

Fig. 5-178

NOTICE: Wipe off the oil completely if spilled.

6. Put in the oil inspection plug and secure it

upon completion of oil replenishment.

7. See "OUTRIGGER STOWING" on page 4-48

to stow the outriggers.

Loading...

Loading...