Section 5 – AUXILIARY WINCH INSPECTION AND MAINTENANCE

Mini-Crawler Crane M A E D A

5-80 1/2019 MC285C-3

Moment Limiter for Operation (Auxiliary

Winch Mode)

WARNING! If you find any abnormality with

the moment limiter, immediately contact us

or our sales service agency.

1. Turn the starter switch to the “ON” position.

2. Check with the working status lamp. The red

light flashes for 2 seconds, then the green

light flashes.

3. Check the moment limiter display unit.

Verify that no error code is displayed at the

“RATED TOTAL LOAD” display on the

display panel. Check if moment limiter is set

as auxiliary winch mode.

4. Start the engine and operate the crane as

follows to verify if the moment limiter properly

displays the value.

Crane Operation and

Displayed Parameter

Value Displayed

on Moment

Limiter

Displayed “boom length”

with the boom length at

minimum

Displayed “boom length”

with the boom length at

maximum

Displayed “working radius”

with the boom length of

“4.4 m” and boom angle of

“29.2 °”

5. Check if displayed actual load value is equal

to the total weight of the load + the hoisting

accessory, when the weight of the known

load is hoisted. There may be slight error in

accuracy depending on boom condition.

6. Operate the crane until the moment limiter

display indicates the boom length is “4.4 m”

and boom angle is “29.2 degrees”, then

measure the “boom angle” and “working

radius.

If the measured value(s) differ from the

moment limiter display value, contact us or

our sales agency.

7. Lift up load and check if boom extending or

boom lowering operation is auto-stopped

when overloaded. If the operation is not

auto-stopped in overloaded condition, stop

using the machine, and contact us or our

agency.

This checking operation must be operated

slowly, and if machine does not auto-stop by

overloading, immediately stop the operation,

and perform recovery operation caused by

overloading.

NOTICE: When measuring actual working radius,

measure from hook offset position.

Replacement of Winch Wire Rope

NOTICE: For more information on the criteria for

wire rope replacement, refer to “Inspecting Wire

Rope.”

Winch Wire Rope - Removal

1. Place the machine on level, hard ground.

2. Push the boom telescoping lever forward to

EXTEND and extend the boom slightly.

3. Push the winch lever forward to DOWN to

ground the hook block.

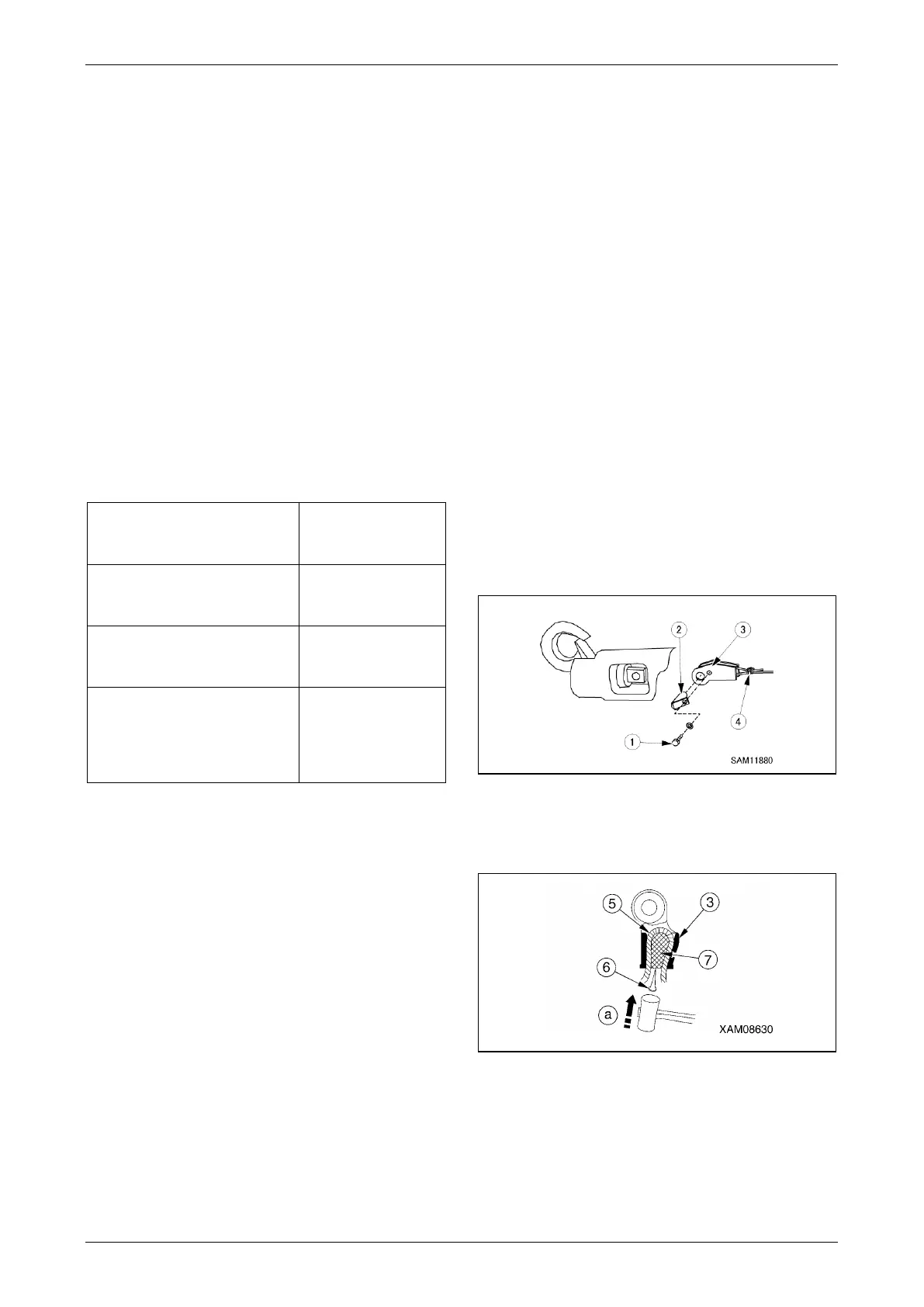

4. Remove wedge socket fixing bolt (1), wedge

socket pin (2), and then remove wedge

socket (3).

Fig. 5-167

5. Remove the wire clip (4).

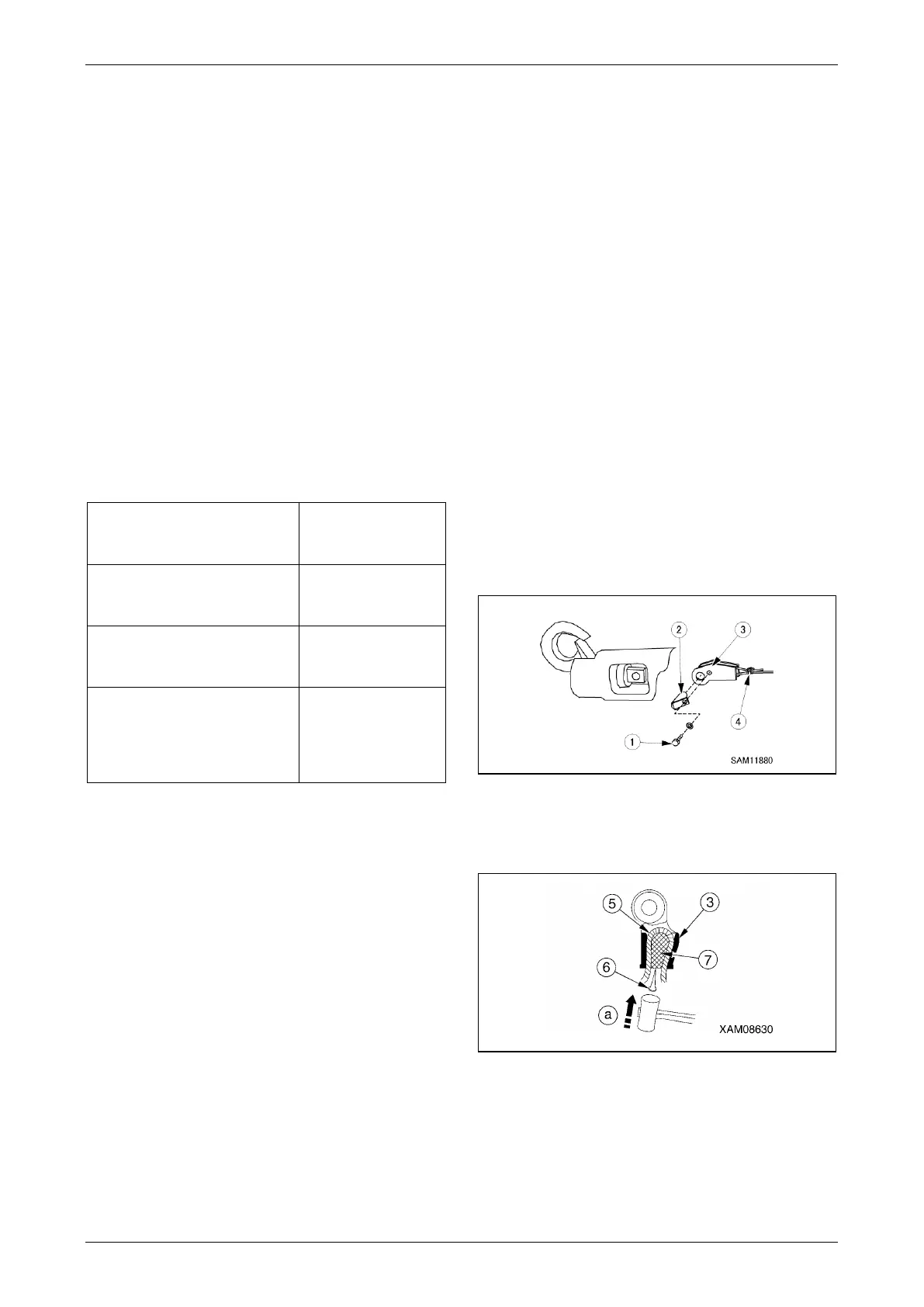

6. Remove wire rope (5) from the wedge socket

(3), using the following procedure:

Fig. 5-168

• Have a piece of round bar (6) with a

diameter of 4 to 6 mm ready and apply it to

rope wedge (7).

• Lightly tap round bar with hammer in the

direction of the arrow (a) to remove the rope

wedge.

Loading...

Loading...