M A E D A Mini-Crawler Crane Section 5 – PERIODIC MAINTENANCE

1/2019 MC285C-3 5-47

Replace Oil in Hydraulic Oil Tank

WARNING! Various parts are at elevated

temperatures immediately after engine

operation.

Do not change the oil immediately. Wait until

the oil is cooled.

WARNING! The oil may spout out when the

filler cap of the hydraulic oil tank is removed.

Loosen the filler cap mounting bolts so that

the filler cap is raised a little to allow the

release of inner pressure, then remove the

mounting bolts and the filler cap.

WARNING! Securely tighten mounting bolts of

the oil filler cap after refilling the oil.

If the mounting bolts are loose the filler cap

may come off during the operation, and the

hot oil may spout out of the pan, causing

burns.

CAUTION: See “LUBRICATING OIL” on page

5-10 for the oil to be used.

CAUTION: Be sure to put the machine in the

travelling posture when checking the oil level.

If you check the oil level in the working

posture, you judge the oil level to be low and

feed the oil excessively.

CAUTION: After replacing the hydraulic oil, do

not start the engine for a while until piping and

hydraulic equipment are filled with the oil.

CAUTION: Avoid the oil exceeding the level

point (red point) of the level gauge.

When the oil goes beyond the correct level, it

may spout out from the air breather during

travelling or crane operation.

Be careful not to let any foreign substance go

into the filler opening when refilling the oil.

• Oil drain pan: Prepare a container of at least

25 L.

• Quantity of oil in hydraulic oil tank for

replacement: 20 L

1. Place the machine on a level surface.

2. See “TRAVELLING POSITION” on page 4-24

and put the machine in the “Travelling

posture”.

3. See “Removing Machinery Cover” on page

5-14 and remove the machinery cover.

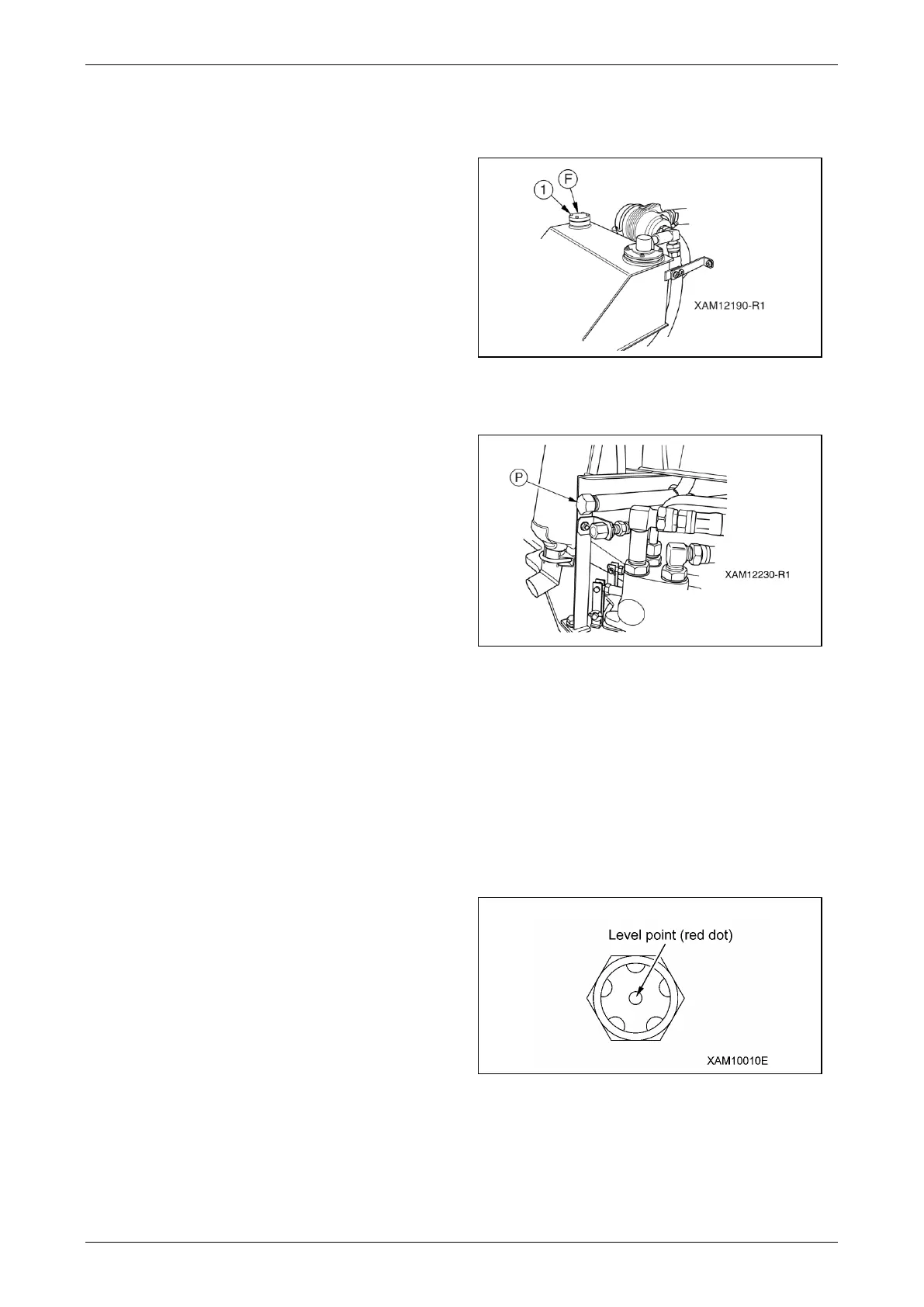

4. Remove the filler cap (F) by removing the

mounting bolts (1) (4 bolts) at the top of the

hydraulic oil tank.

Fig. 5-81

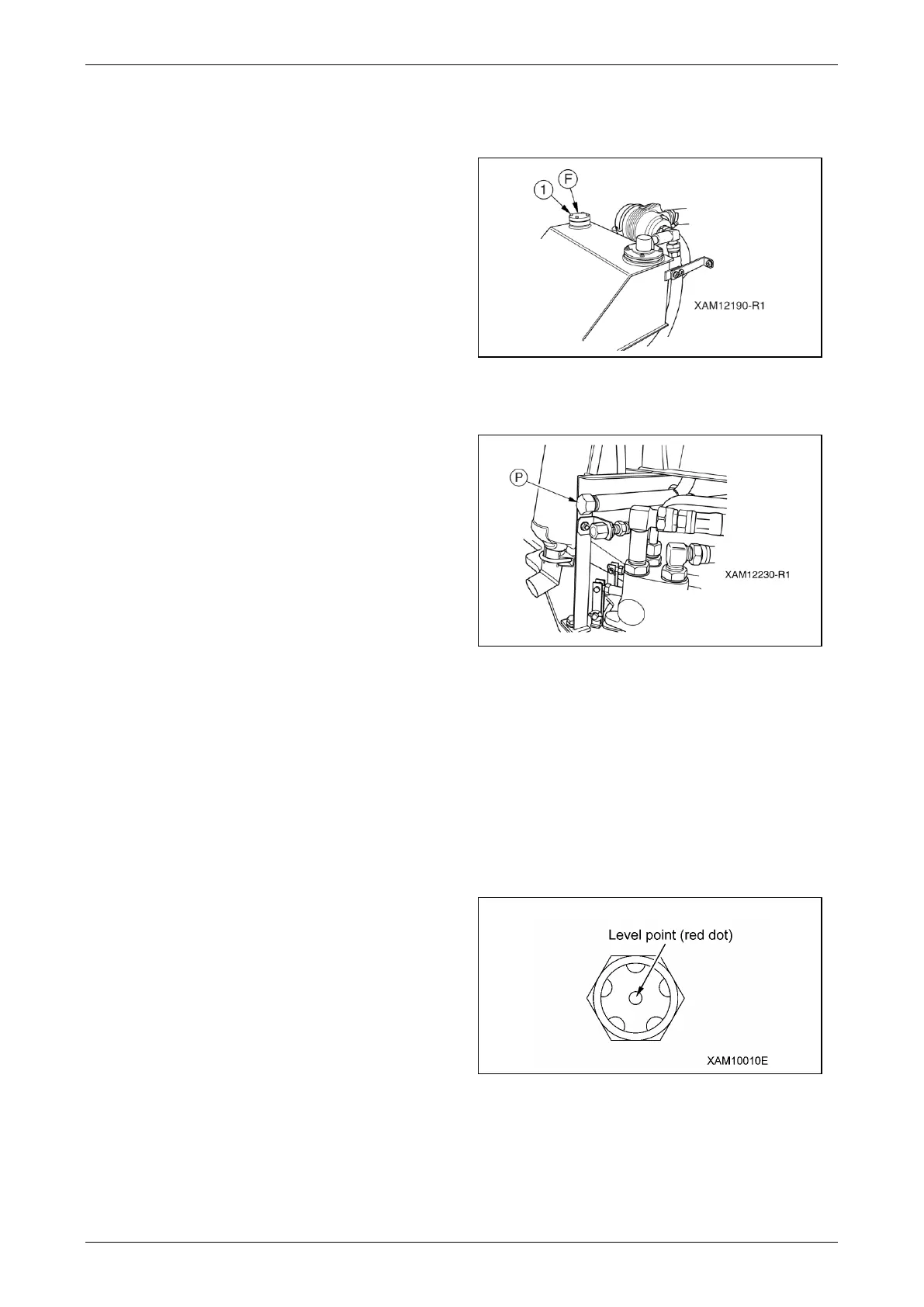

5. Place a drain pan directly underneath the

drain port cap (P) to receive drained oil.

Fig. 5-82

6. Remove the drain port cap slowly to drain the

oil, keeping from contact with draining oil.

7. Check the drained oil and if it contains an

unacceptable amount of metal particles or

foreign matter, contact our sales service

agency.

8. Install the drain port cap.

9. Feed hydraulic oil through the filler port to the

level point (red dot) while looking at the oil

level gauge.

Fig. 5-83

10. After refilling the oil, set the filler cap and

tighten the mounting bolts (4 bolts) securely.

11. See “Installing Machinery Cover” on page

5-14 and install the machinery cover.

12. Bleed the air according to the following

sequence.

Loading...

Loading...