Integritest Exacta Filter Integrity Test Instrument

Operating and Maintenance Manual Troubleshooting 205

INTRODUCTION

Some of the problems commonly encountered during filter testing can be easily corrected.

Satisfactory solutions, however, are most often derived from:

• careful diagnosis of the problem

• recording the circumstances related to the failure

• recording the nature of the failure

• a systematic approach towards solving the problem

General Troubleshooting Procedure

Determine if the problem is due to the application (i.e., the filter system) or to the operation of

the instrument.

• This can be determined by conducting a referee integrity test simultaneous with an

instrument test. The simultaneous referee test will give an objective test result that can

verify if the instrument is operating properly.

If there is an application issue check the following:

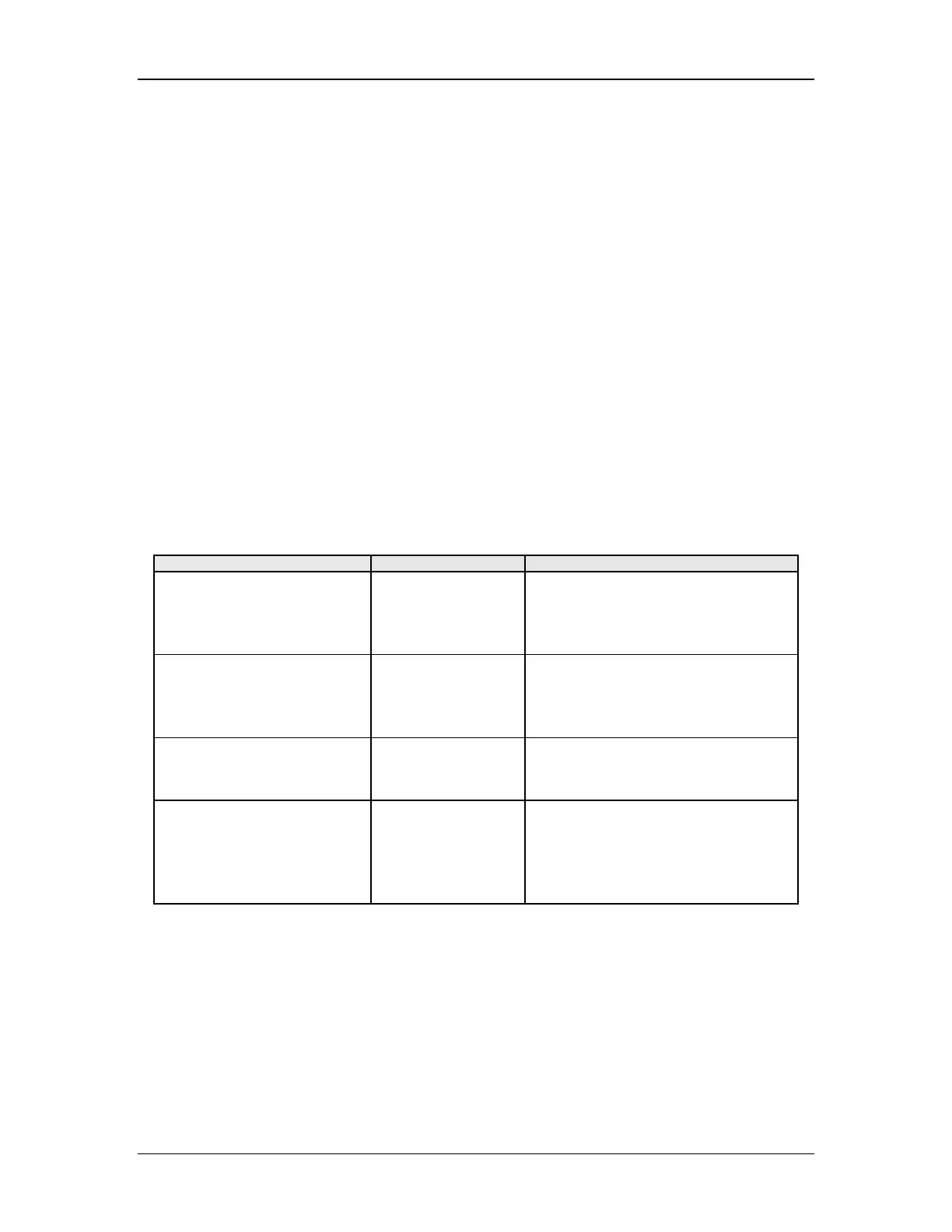

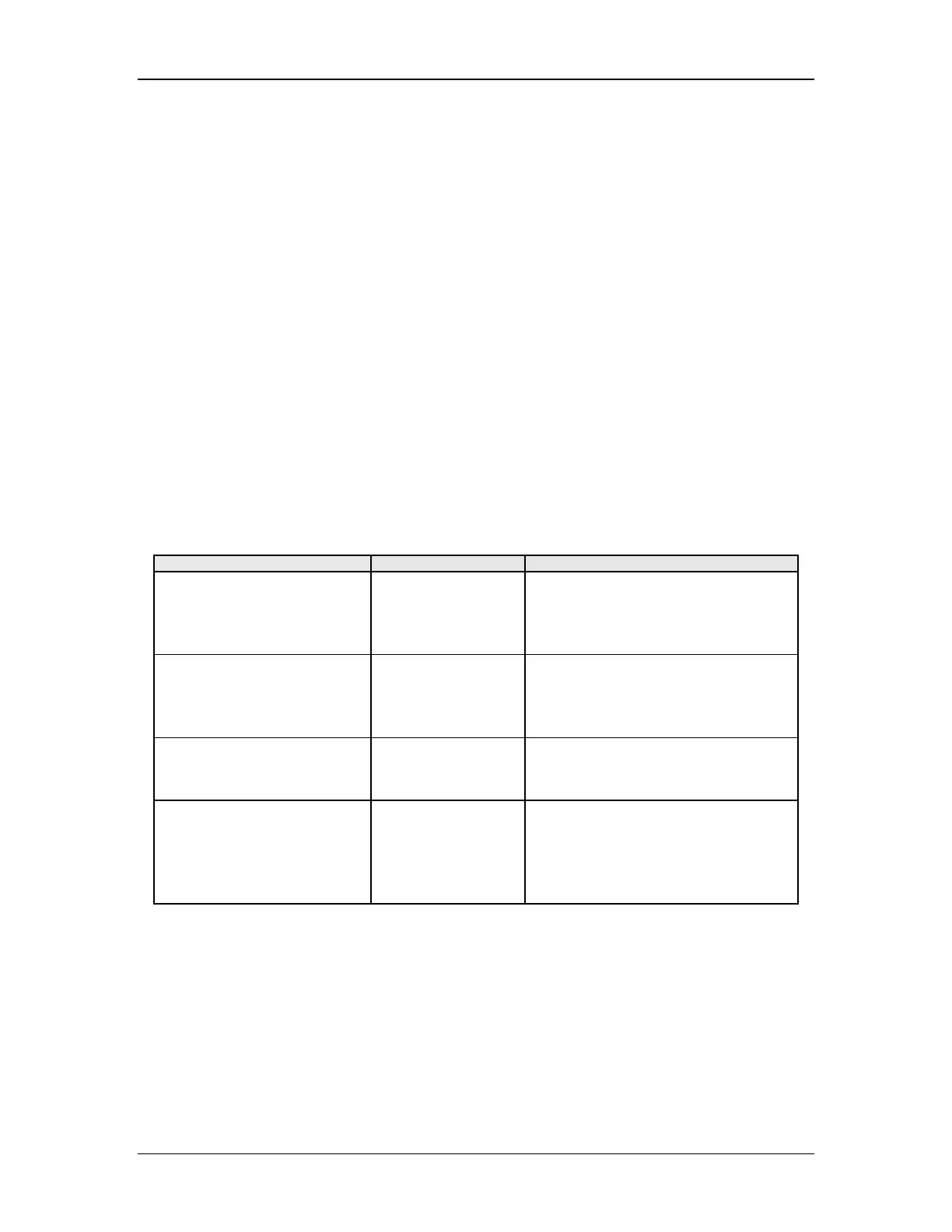

Table 24: Troubleshooting Testing Problems

Problem Type of Test Impacted Problem Resolution Options

Improper filter wetting

resulting in higher diffusion

values and/or lower bubble

point values.

Bubble Point &

Diffusion

Rewet the filter using flow thru

wetting (See Millipore Wetting Insert

for specific instructions)

Improper filter drying

resulting in high HydroCorr

test values.

HydroCorr Dry the filter (See Millipore

Validation Guide - HydroCorr

Integrity Test Specifications - for

specific instructions)

Temperature variations

resulting in inaccurate test

results.

All Tests Use room temperature test fluid.

Maintain constant temperature

during the test.

Filter contamination

resulting in inaccurate test

results.

All Tests Flush the filter and re-wet.

Also, if the contamination is from

the product being filtered, consider

establishing product bubble point

specifications.

If there is an instrument operation issue, check the following:

• Make sure that the Integritest Exacta instrument is plugged into a properly grounded

wall outlet and that there is power to that outlet.

• Check all pneumatic connections to the Integritest Exacta instrument and make sure all

connectors are firmly attached.

• Verify that the gas source is connected to the INLET connector on the pneumatic

module and that the gas supply is turned on.

• Confirm that the gas source is supplying 35–100 psig of clean dry air or nitrogen.

Loading...

Loading...