Millipore System Documentation Set

28 Operating and Maintenance Manual Publication XITXSP121 P Rev.A

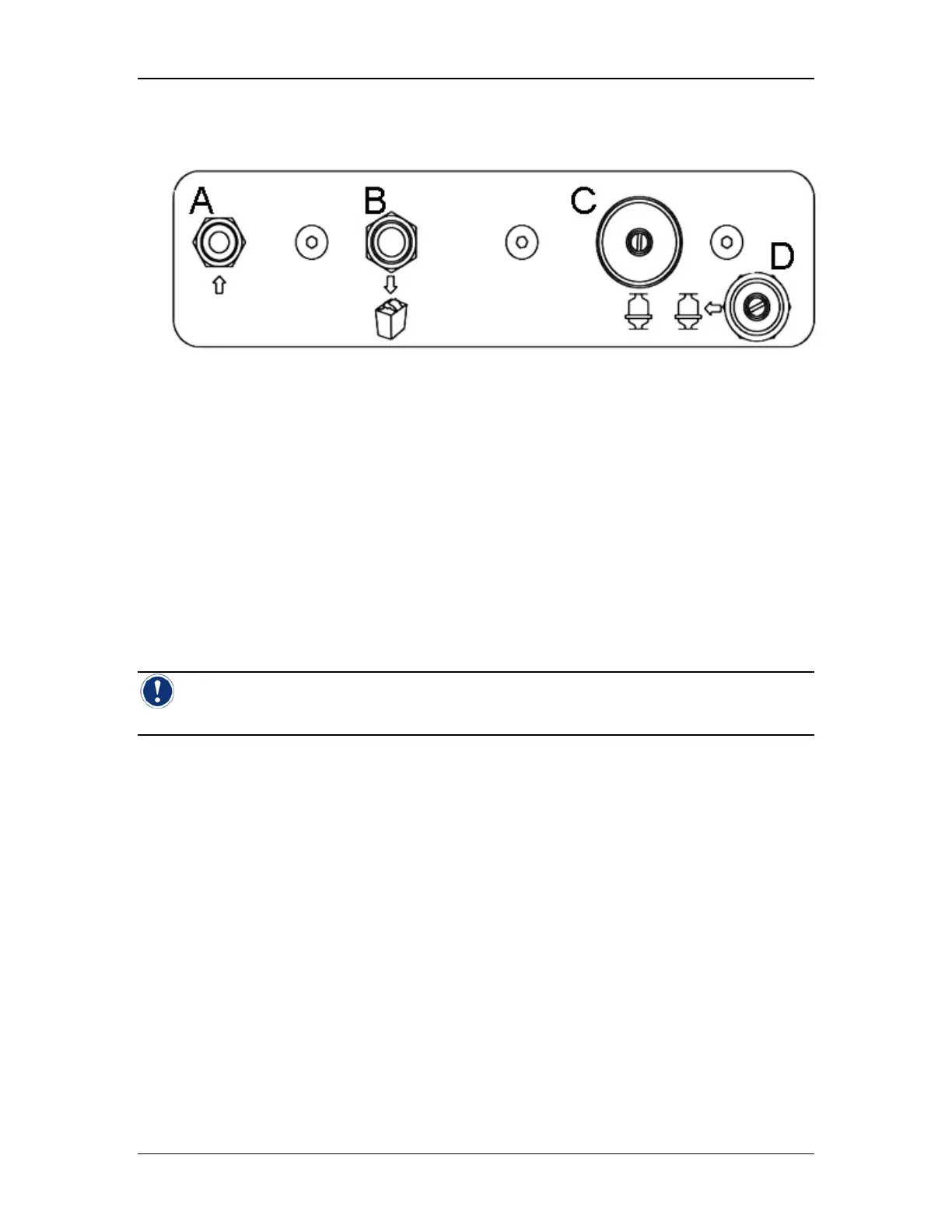

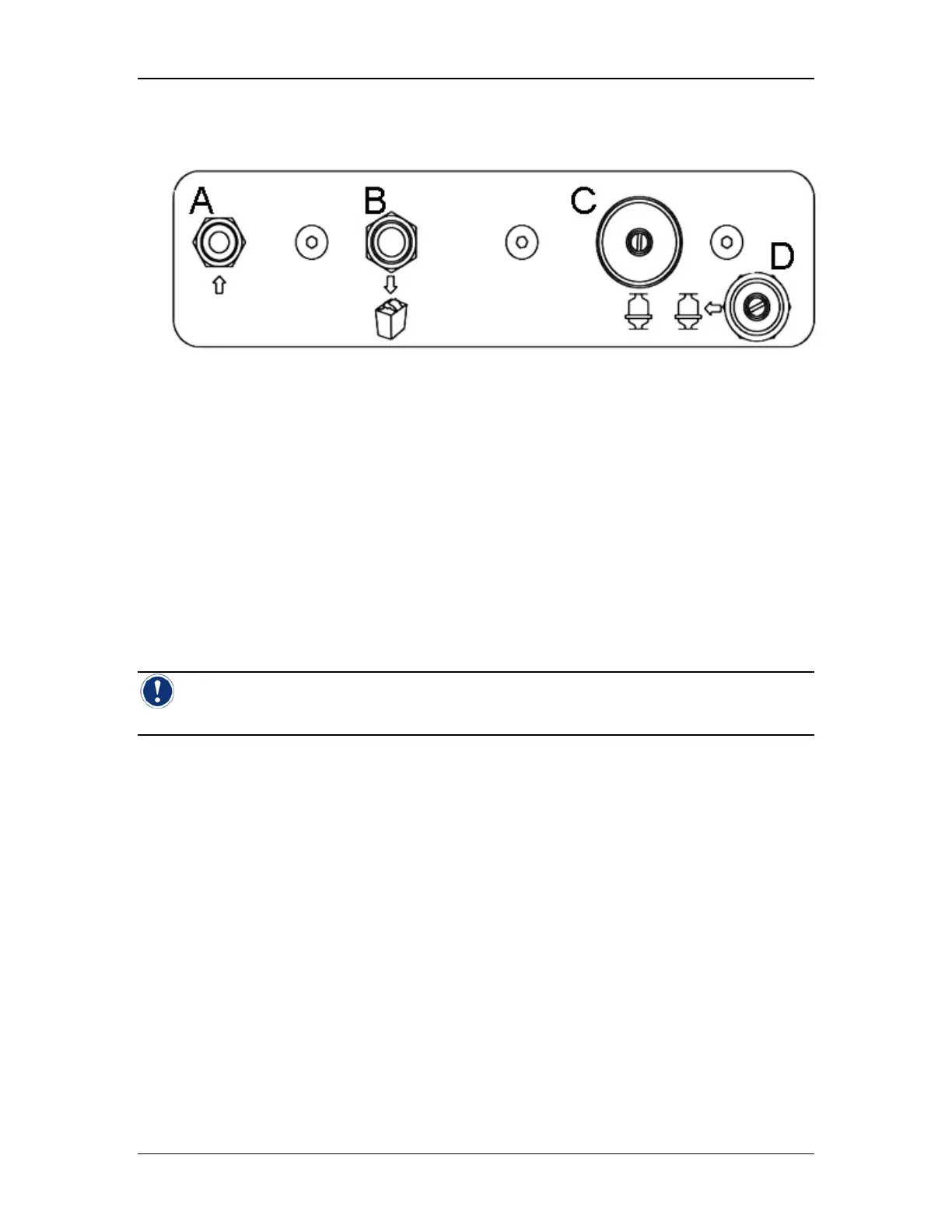

Pneumatic Connections

Diagram Key: A. Gas Inlet (see Gas Supply Requirements below)

B. Exhaust

C. From Housing

D. To Housing

Figure 4: Side Panel

• Gas Inlet (quick disconnect labeled “Air Inlet”)

• Exhaust (tubing connector)

• Outlet (dual quick disconnects labeled “From Housing” and “To Housing”)

Gas Supply Requirements

The instrument must be connected to a regulated supply of clean dry air (>-20 C dew point) or

nitrogen at 35–120 psig (2.4–8.5 bar).

Note: To minimize the likelihood of water contamination, it is recommended that the inlet

gas be filtered with an external coalescing filter.

Gas Inlet Connection

To Gas Supply

• Do not remove the gas inlet filter or damage to the instrument may result.

• Connect a regulated supply of clean dry air or nitrogen, 35–120 psig (2.4–8.5

bar), to the inlet tubing assembly of the instrument using the ¼” NPTF side of the

gas filter.

• Supply at least 15 psi (1.02 bar) more than the maximum pressure required to

perform the filter test.

To Instrument

• Slide quick disconnect fitting of Integritest Exacta inlet tubing assembly onto the

connector stem labeled Air Inlet.

• Grasp the rear of the connector and push it firmly against the connector stem. Do

not grasp the flared section when making a connection. This section must be able

to slide freely into place

• Release it when you hear it click into place.

Loading...

Loading...