530 7 ELECTRONIC CONTROL SYSTEMS DIAGNOSTICS

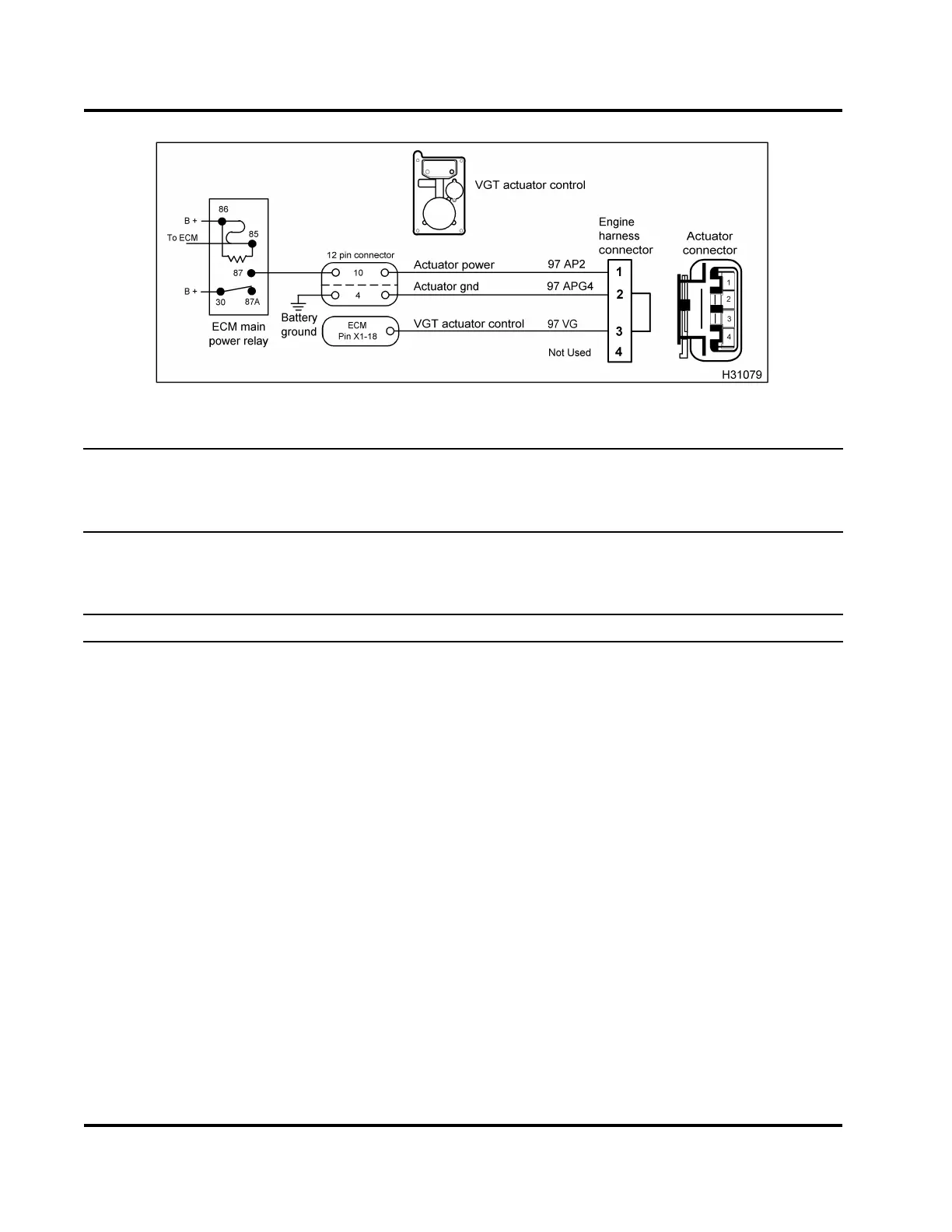

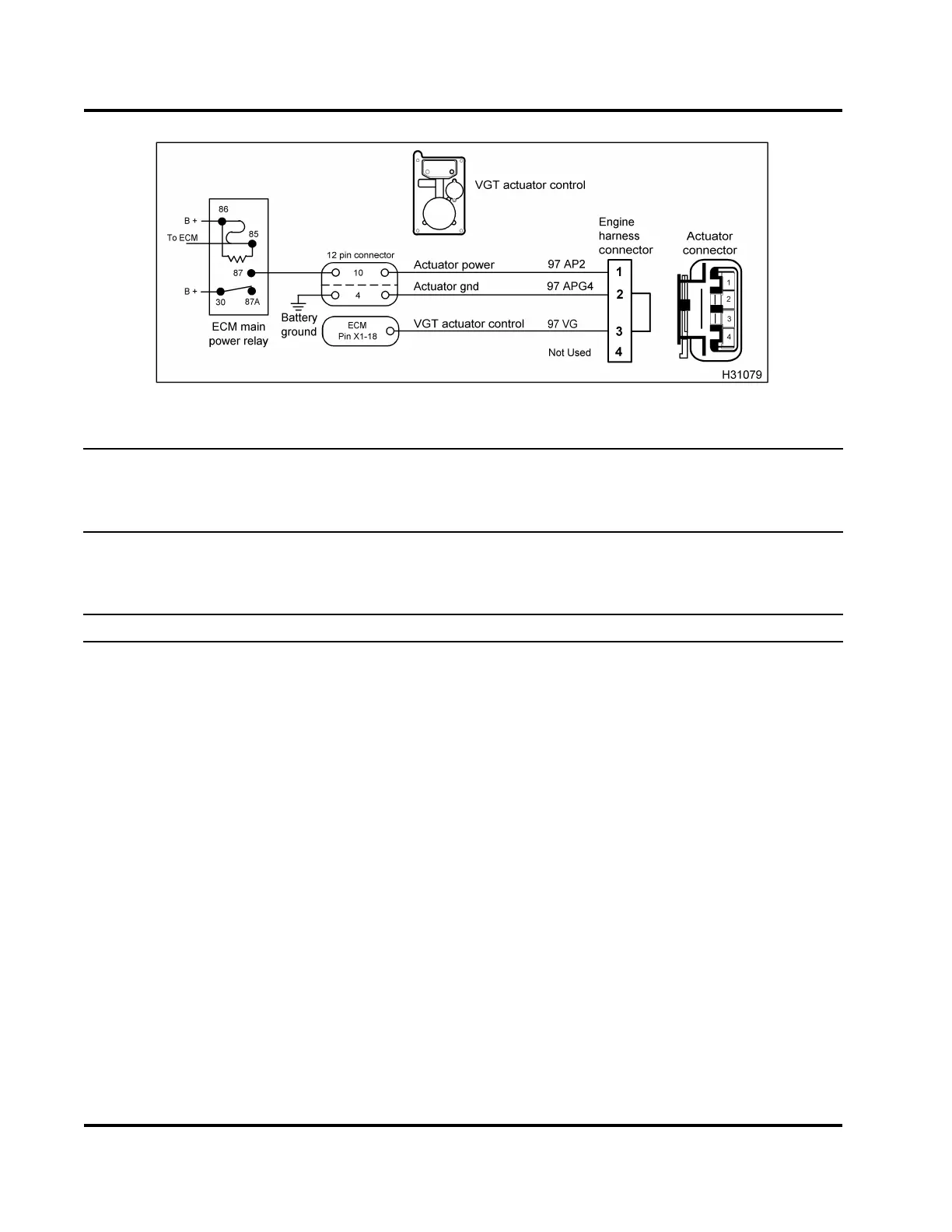

Figure 501 VGT circuit diagram

NOTE: Turn the ignition switch to OFF before disconnecting engine wiring harness connectors from

components.

See truck Ch assis Electrical Circu it D iag ram Manual for circuit numbers, connector and fuse locations.

Output State Test - Signal Check (Actuator Control Vo ltage check has been completed. Pin 2 to ECM

Chassis Ground is to specification. Co n ne c t Turbo Breakout H arness to engine harness an d actuator

harness. Run the Low and High Output State Tests. See “Diagnostic Software Operation” in Section 3 (page

68) for procedure to do the Low and High Output State Tests.)

Test State/Point Setting/Spec Comment

Output State Test -

Low

DMM set to V -

DC

Listen and observe to verify if crank leve r of VGT actuator

moves. Toggling between the Low and High Output State Tests

can be done during this test.

3to2 0Vto0.25V

If > 0.25 V, disconnect actuator harness and connect 500 Ohm

Resistor Harness between 3 and 2. Retest Output State Test

-Low.

• If > 0.25 V the concern is with engine harness or ECM,

check for a short to B+ or V

REF

. Do the Actuator Control

Voltage Check at ECM (page 534) and Harness Resistance

Checks (page 537).

• If < 0.25 V, the concern is either high resistance in wiring or

the VGT actuator. Do Harness Resistance Checks (page

537) to confirm integrity of wiring. See Chassis Electrical

Circuit Diagram Manual.

If integrity of wiring is confirmed to be in good condition,

replace VGT actuator.

Output State Test -

High

DMM set to V -

DC

Listen and observe to verify if crank leve r of VGT actuator

moves. Toggling between the Low and High Output State Tests

can be done during this procedure.

3to2 B+±0.5V

If < B+, disconnect actuator harness and connect 500 Ohm

Resistor Harness between 3 and 2. Retest Output State Test

-High.

EGES-270-1

Read all safety instructions in the "Safety Information" section of this manual before doing any procedures.

Follow all warnings, cautions, and notes.

© August 2008 Navistar, Inc.

Loading...

Loading...