Page 31

STAT

IM

2000/2000S Service Guide

96-108639 Rev 3.0

2. Tools, Maintenance Schedules, Procedures and Testing

STATIM 2000/2000S/2000 G4 Service Guide

Annual Service Requirements

Important notes:

t The following schedule is designed as a guide for SciCan approved trained service

engineers and applies to all STATIM 2000/5000/G4 models.

t The operations contained in this guide are for use during standard service intervals

on functioning machines. Any operations or components required over and above this

guide will be at the discretion of the service engineer and the customer and additional

to the requirements outlined below.

t Components other than the routine annual service components may require changing

due to wear and tear or failure but only require changing as and when degradation or

failure occurs and should not need to be changed routinely on an annual basis. These

may be identified during service and changed as appropriate.

t Consumable items such as seals and filters may require changing at more frequent

intervals outside of normal service intervals dependent on the frequency of use of the

unit.

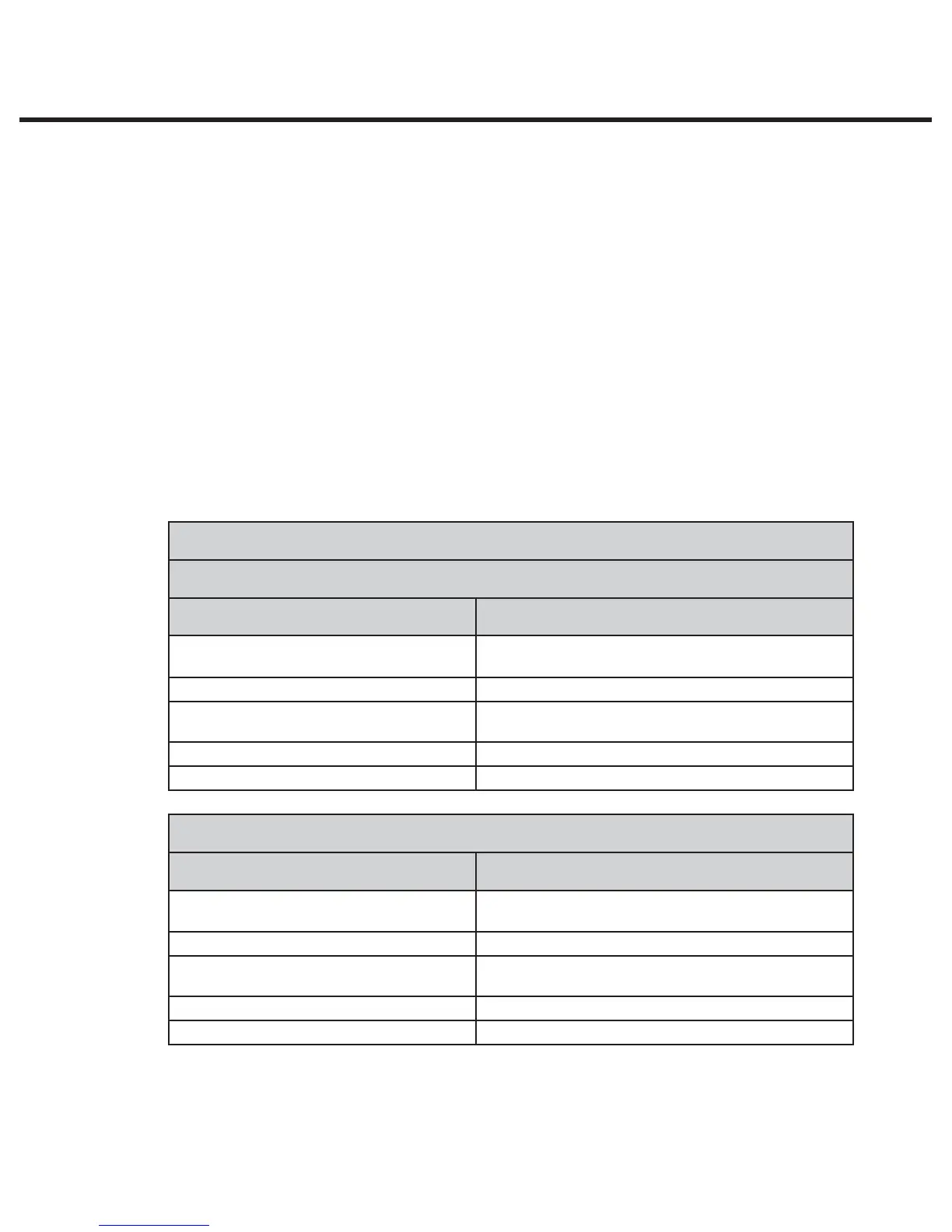

SERVICE SCHEDULE

Standard service parts required for STAT

IM

2000/2000S and G4 variants:

Part Number Description

01-100028S Seal and Lubricant kit A/B

01-100207S Filter for air compressor, STAT

IM

2000/2000S (where fitted)

01-102119S Filter Biological, B/C (where fitted)

01-100574S Check valve, B

01-100998S Repair, Solenoid valve (Honeywell) A/B/C/D

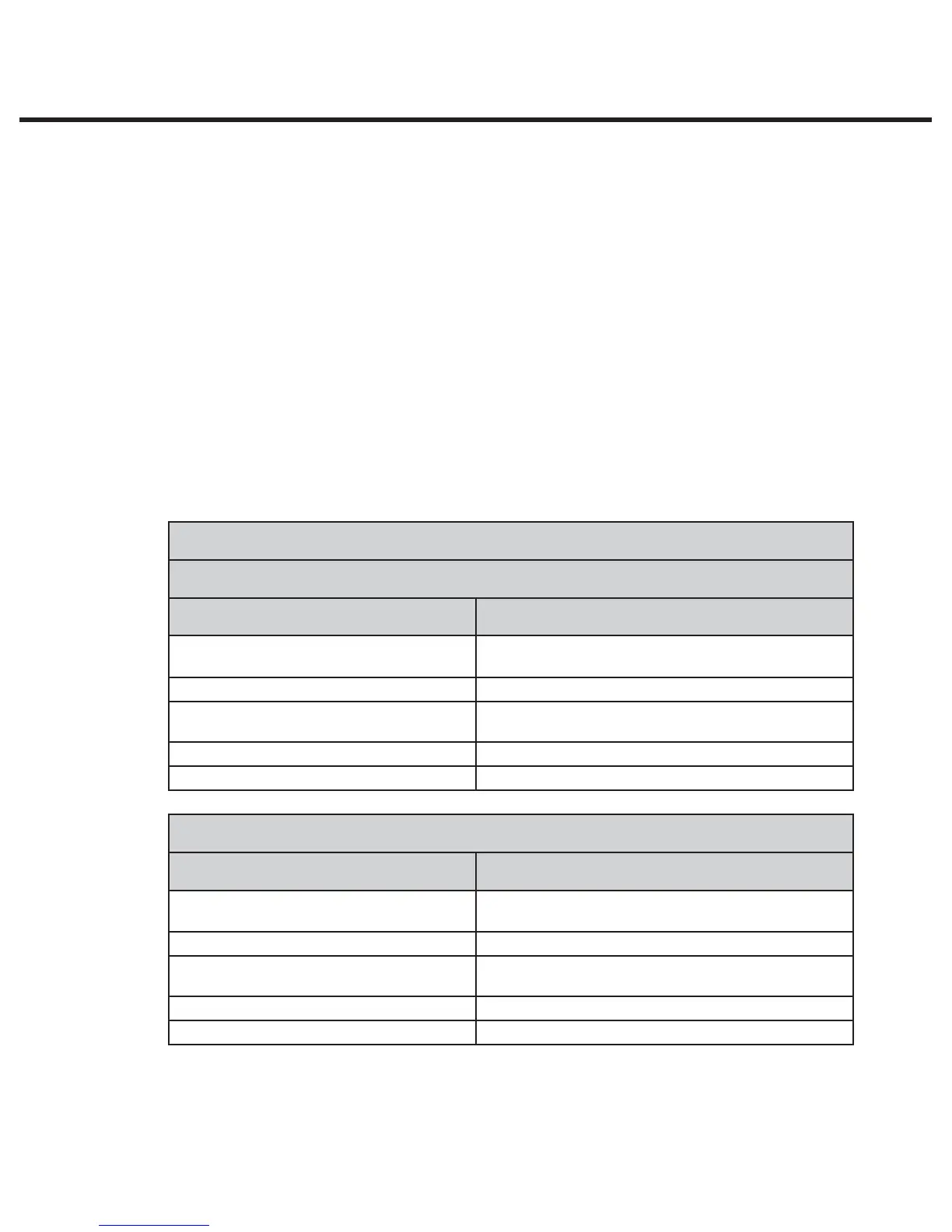

Standard service parts required for STAT

IM

5000/5000S and G4 variants:

Part Number Description

01-101649S Seal and Lubricant kit C

01-101652S Filter for air compressor, STAT

IM

5000/5000S (where fitted)

01-102119S Filter Biological, B/C (where fitted)

01-101627S Check valve, C

01-100998S Repair, Solenoid valve (Honeywell) A/B/C/D

Loading...

Loading...