Page 66

STAT

IM

2000/2000S Service Guide

96-108639 Rev 3.0

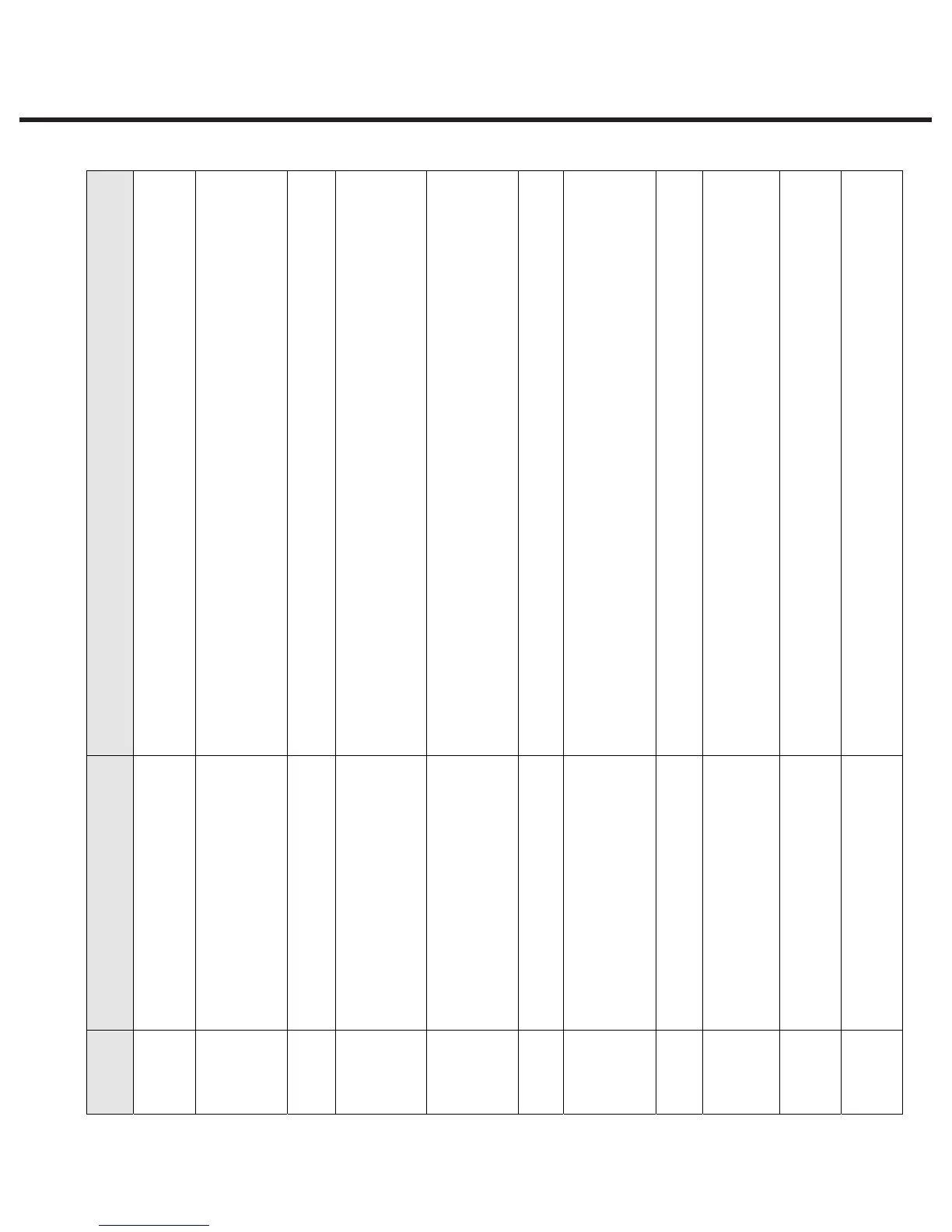

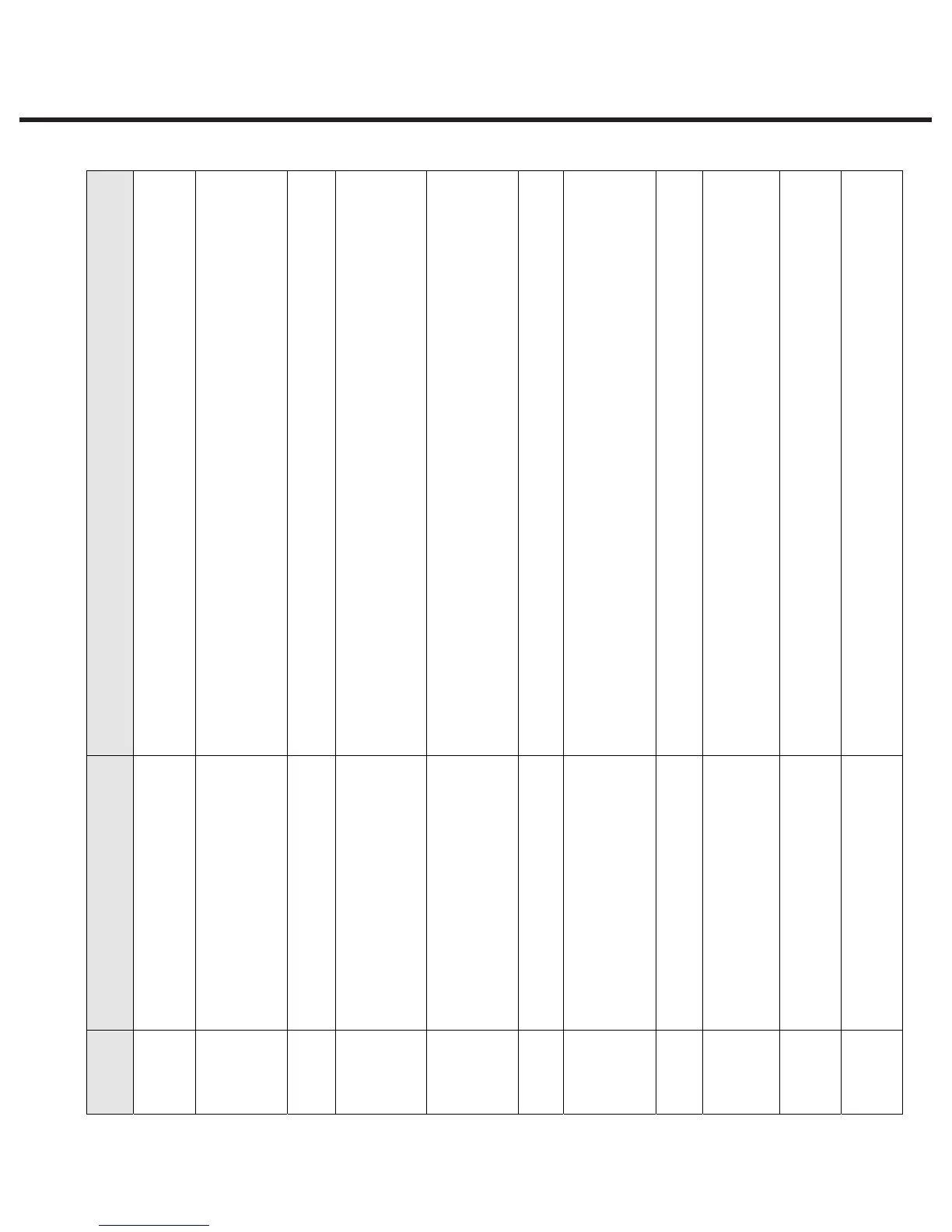

3. Troubleshooting Cycle Faults

STATIM 2000/2000S/2000 G4 Service Guide

Check

Cassette

#6

The steam generator temperature is more

than 5°C higher than the chamber

temperature.

Most probable causes are a blocked duct, a blocked solenoid valve, miscalibration or a pinched

exhaust tube.

Check

Cassette

#7

The cassette temperature has dropped

below 130.5°C during the sterilizing phase

of the UNWRAPPED or WRAPPED Cycle,

or below 117.5°C during the sterilizing

phase of the RUBBER & PLASTIC

Cycle.

Most probable cause is a faulty solenoid valve.

Check

Cassette

#8

The chamber temperature is more than 5°C

higher than the steam generator

temperature.

Most probable causes are thermocouple miscalibration or very strong pump delivery.

Check

Cassette

#9

This is a special error message for the U.K.

market. The chamber temperature has

exceeded 139°C during the UNWRAPPED/

WRAPPED Cycle, or has exceeded 126°C

during the RUBBER & PLASTIC Cycle.

Most probable causes are a blocked or faulty solenoid valve or a pinched exhaust tube.

Service

Needed

The steam generator temperature has

exceeded 170°C, chamber temperature has

exceeded 147°C, or the thermocouple is

faulty.

Most probable causes are a blocked or faulty solenoid valve, a pinched exhaust tube, a broken

thermocouple lead, an open, disconnected or defective thermocouple, a weak pump or a

contaminated steam generator.

Check

Cassette

(without a

number)

The cassette temperature has failed to drop

to 103°C within a timeout period at the end

of a cycle.

Most probable causes are a blocked exhaust duct in the cassette, a blocked or faulty solenoid

valve or a pinched / kinked exhaust tube.

CF

number

Description of Error Message

Probable Cause of Error Message

Check

Cassette

#1

The cassette temperature failed to reach

95°C in 3 minutes.

This error message occurs only during warm up. The most probable causes are:

1. Steam generator does not heat up. No power to steam generator. Blown thermal fuse.

2. Check for a large cassette leak or a large load.

Check

Cassette

#2

The cassette temperature failed to increase

from 95°C to 100°C within 1 minute 20

seconds.

Most probable causes are a faulty cassette seal, miscalibration, a damaged cassette, improperly

adjusted or failed microswitch allowing unit to function when cassette is not fully inserted.

Occasionally, a low pressure weather system in higher altitude sites will alter the boiling

temperature significantly and trigger this fault.

Verify Vref to be 4.0V.

Check

Cassette

#3

The cassette has failed to pressurize and

achieve a temperature of 110°C within 70

seconds of pressurization.

This may be caused by a faulty or worn cassette seal, a faulty or dirty solenoid valve, a damaged

cassette or a faulty exhaust tube, leaky check valve or pressure relief valve.

Check

Cassette

#4

The cassette has failed to achieve

sterilization conditions within 10 minutes of

the chamber first reaching

102°C.

Several conditions may cause this: a damaged or worn cassette seal, a faulty solenoid valve,

improperly installed copper tubing, cassette thermocouple misalignment or damage, a faulty

steam generator pressure relief valve or a faulty check valve on.

Check

Cassette

#5

The software causes the pump to activate

while between 2 minutes 44 seconds and 2

minutes 24 seconds remaining in the cycle.

If a request to pump water occurs outside of

2 minutes 44 seconds, Check Cassette #5

occurs.

This indicates a substantial steam leak from the cassette, a contaminated steam generator or a

weak pump.

Cycle Fault Numbers and descriptions on units with revision 3.x and 4.x type controller boards

Loading...

Loading...