Page 75

STAT

IM

2000/2000S Service Guide

96-108639 Rev 3.0

3. Troubleshooting Cycle Faults

STATIM 2000/2000S/2000 G4 Service Guide

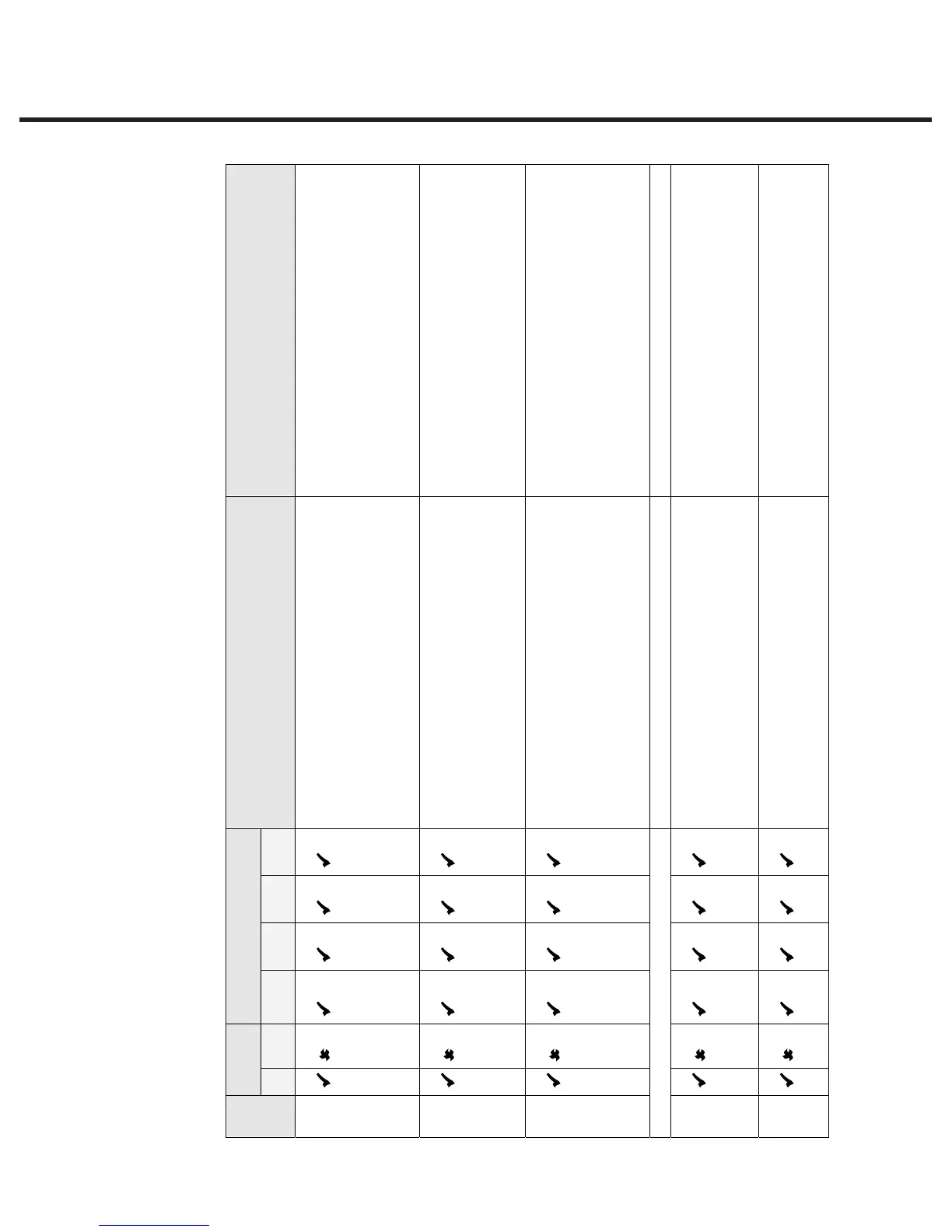

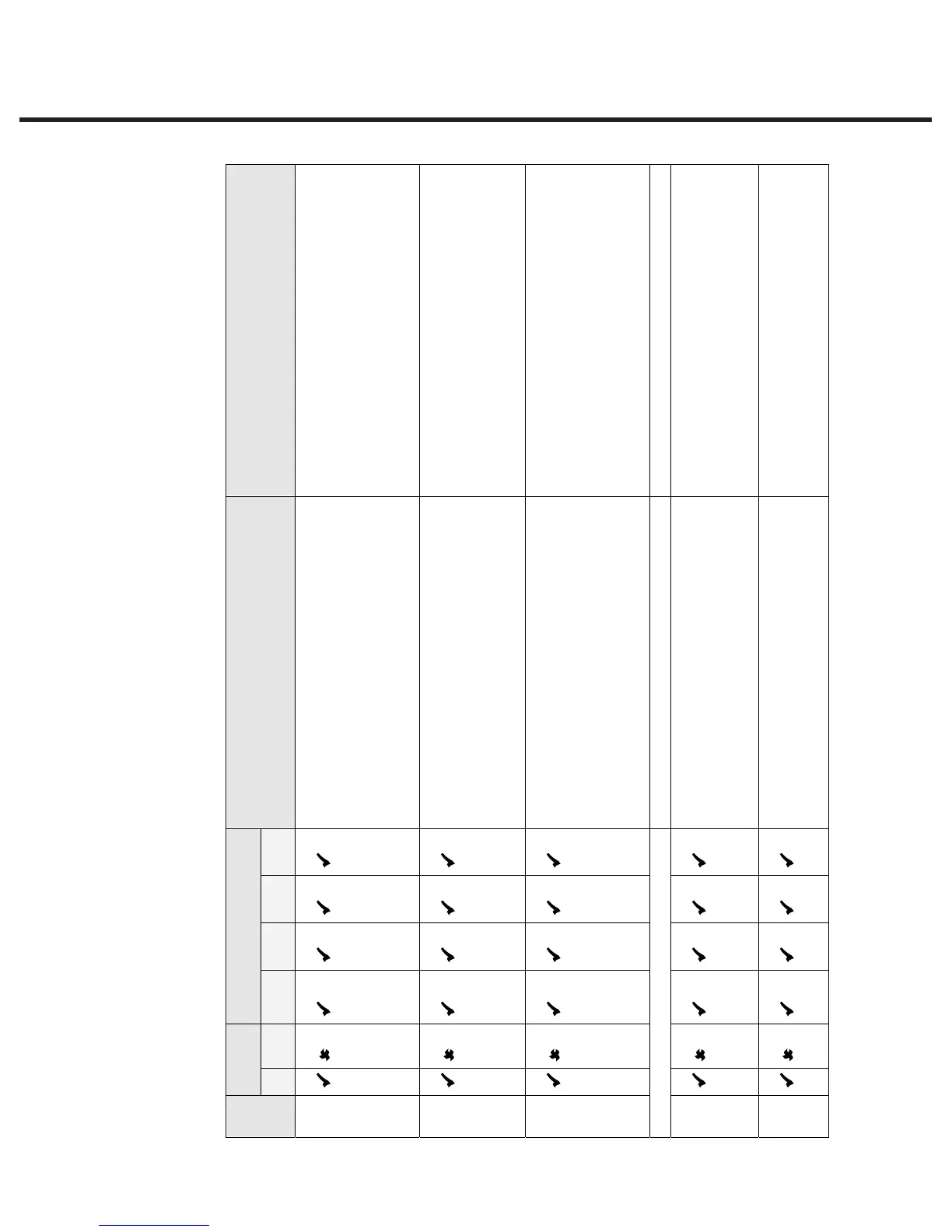

CF

No.

Unit

type

Software revision

Description of Fault

Probable Cause (or causes) of Fault

S Non

S

1.xx/

2.xx

4.xx 5.xx 6.xx/

7.xx

63

For a 134°C cycle, the theoretical chamber

temperature as calculated from the measured

chamber pressure was more than 2°C above the

measured chamber temperature, allowing for

measurement error.

% Calibration imbalance (pressure

transducer or chamber thermocouple)

% Sticking solenoid valve (closed)

% Failed solenoid coil

% Blocked cassette exhaust duct

% Obstructed exhaust tubing (kink)

% Poor air removal

64

For a 134°C the theoretical cassette

temperature calculated from the measured

cassette pressure was below the sterilization

temperature, allowing for measurement error

(i.e. Pchm < 304 kPa).

% Calibration imbalance (pressure

transducer or chamber thermocouple)

% Poor air removal during conditioning

(exhaust blockage).

% Not able to generate steam

%

Steam leak in the system

65

For a 134°C cycle, the theoretical cassette

temperature calculated from the measured

cassette pressure was more than 4°C above the

sterilization temperature, allowing for

measurement error (i.e. Pchm > 341.2 kPa).

% Calibration imbalance (pressure

transducer or chamber thermocouple)

% Sticking solenoid valve (closed)

% Failed solenoid coil

% Blocked cassette exhaust duct

% Obstructed exhaust tubing (kink)

%

Poor air removal

66 - 69

Not used

70

The time maintained by the internal timer of the

processor didn’t match the time maintained by

the external real-time clock.

%

Transient electromagnetic disturbance

(problem won’t repeat).

% Damaged microprocessor or crystal

(STATIM Controller Board).

% Damaged real-time clock or crystal

71

Pressure reading is outside the possible range

% Misconnected, disconnected or

damaged pressure sensor.

% Disconnected or damaged Pressure

Sensor Interface Board (not rev 7.xx).

Loading...

Loading...