Motor control

SIMOCODE pro

4-38 GWA 4NEB 631 6050-22 DS 03

Notice

Two set currents must be set for this control function:

• I

s

1 for the slow speed

• I

s

2 for the fast speed.

Depending on the current range, the current can in many cases be directly

measured at both speeds with a single current converter. Otherwise you

will need two external current converters according to the corresponding

speed (e.g. 3UF18 with a 1 A secondary transformer rated current), whose

secondary cables must lead through the current measuring module with the

range 0.3 - 3 A. The set current I

s

1 or I

s

2 must be converted according to

the secondary currents of the external transformers. For further information,

see Chapter 3.2 "Overload protection".

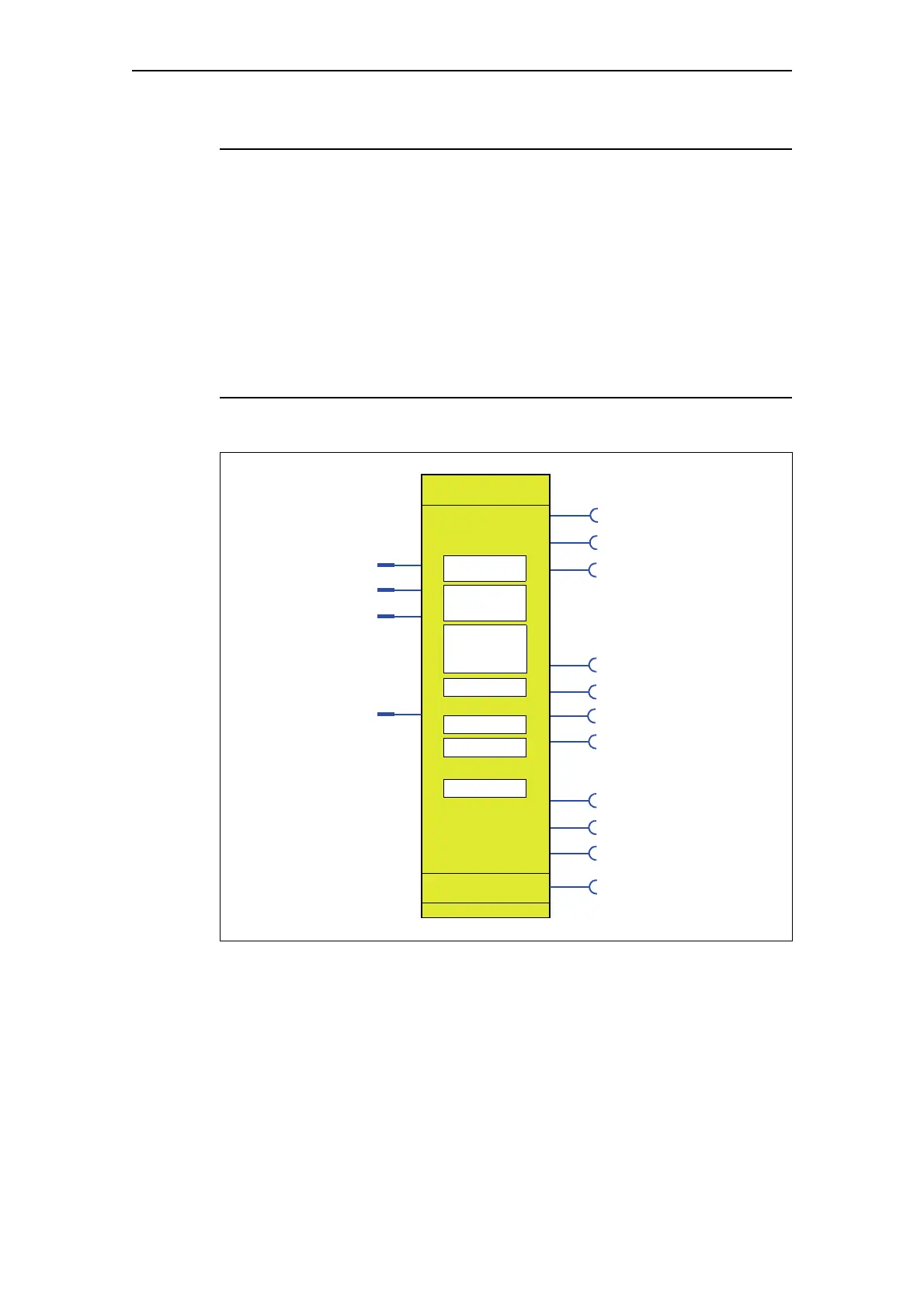

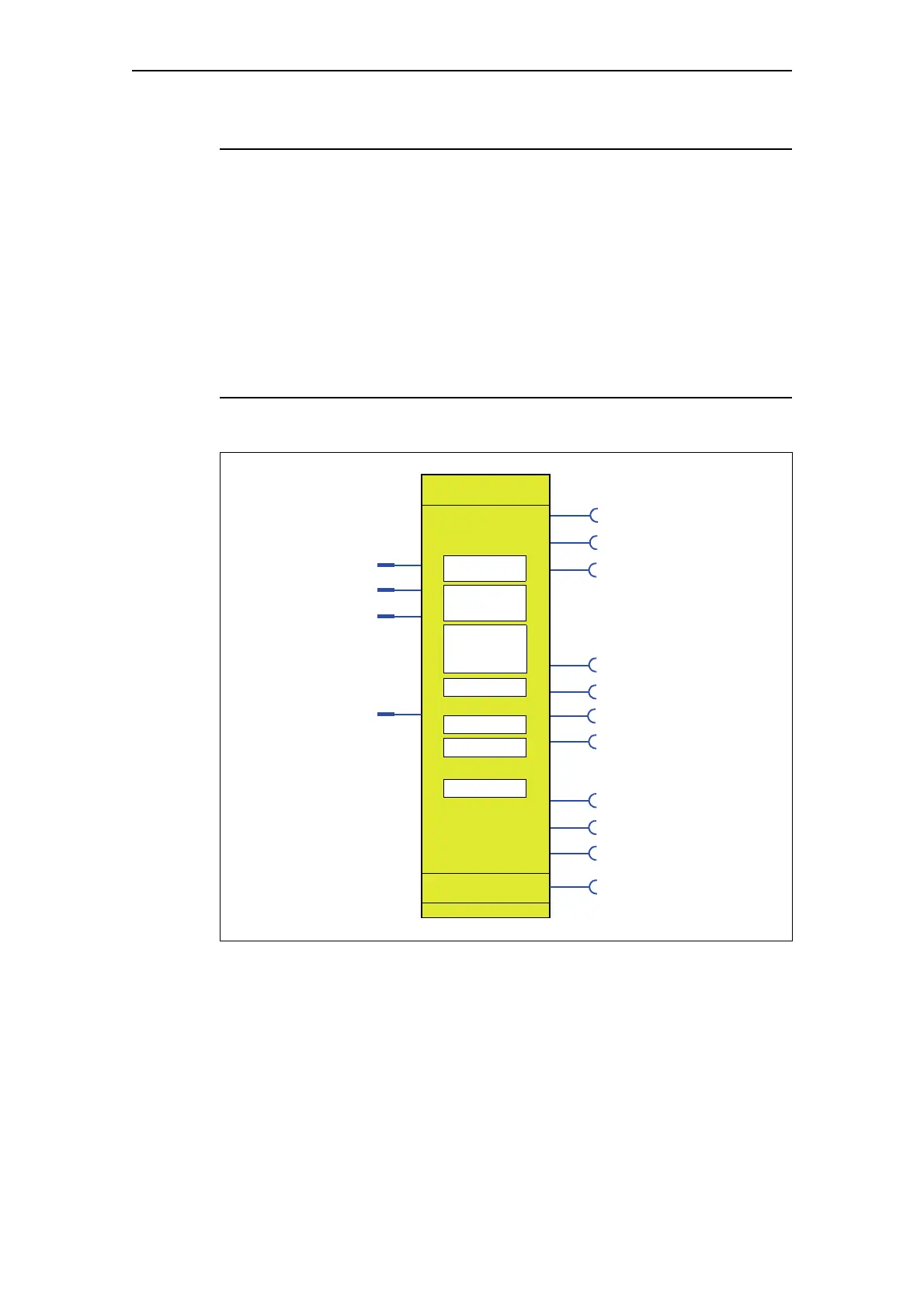

Schematic

Fig. 4-18: Schematic of the "Dahlander" control function, "Protection/Control" function block

Control commands

Auxiliary control inputs

Contactor controls

Displays

Status

QE1

QE2

FB ON*

QLA

QLE>

QLS

OFF

ON >

OFF

ON >

(ON >)

(OFF)

(Fault)

QE3

*Feedback ON

ON >>

ON >>

QLE>>

(ON >>)

Protection/Control

Non-maintained

Change-over

command Saving

Dahlander

Motor protection

Change-over pause

active

FAST

SLOW

Star contactor FAST

Extended control

Feedback time

Execution time

Load type

Change-over pause

Separate failsafe

function from

command mode

control function

Loading...

Loading...