5

05.01

5.8 Control module “SIMODRIVE 611 universal E”

5-141

Siemens AG 2001 All rights reserved

SIMODRIVE 611 Planning Guide (PJU) – 05.01 Edition

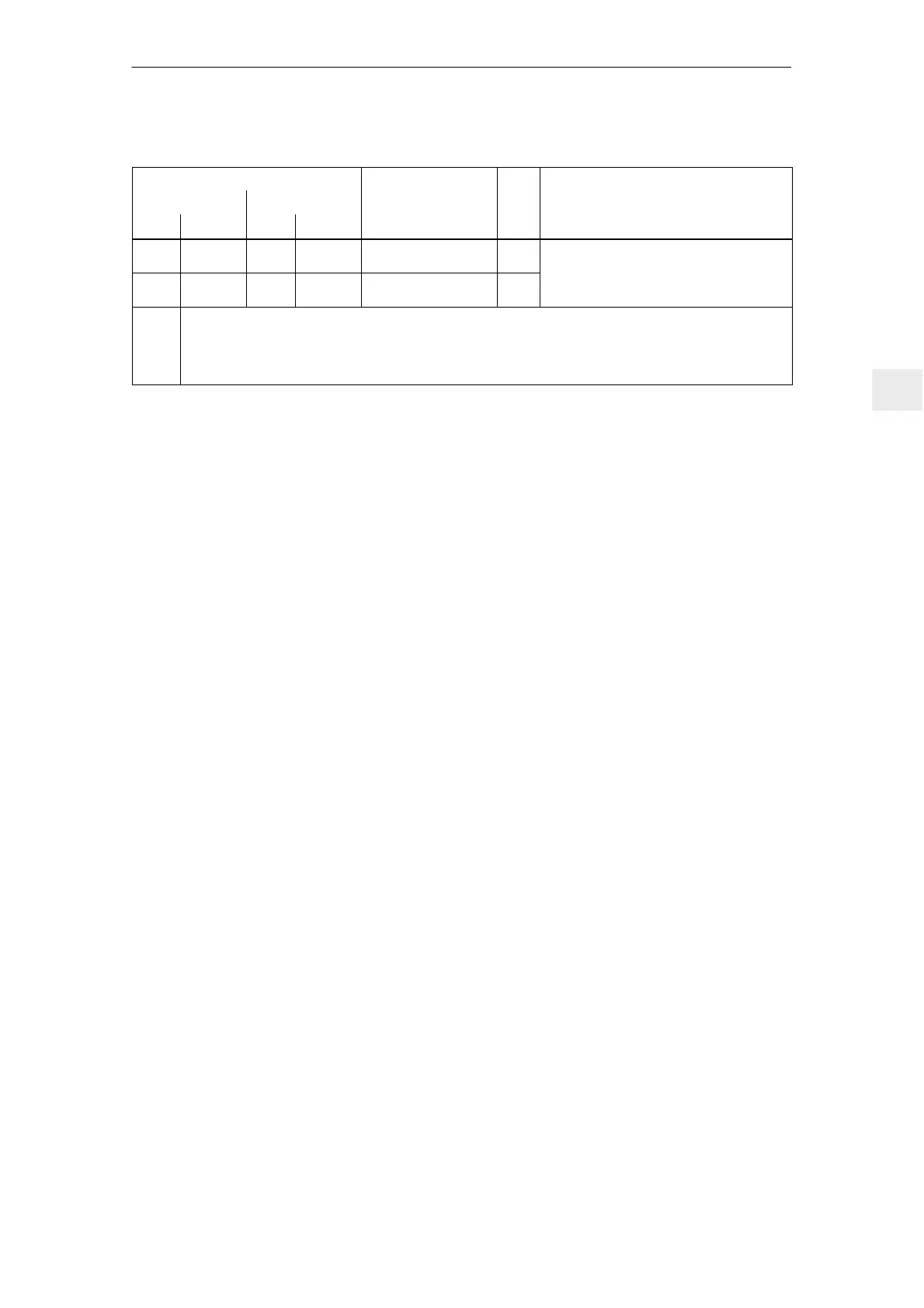

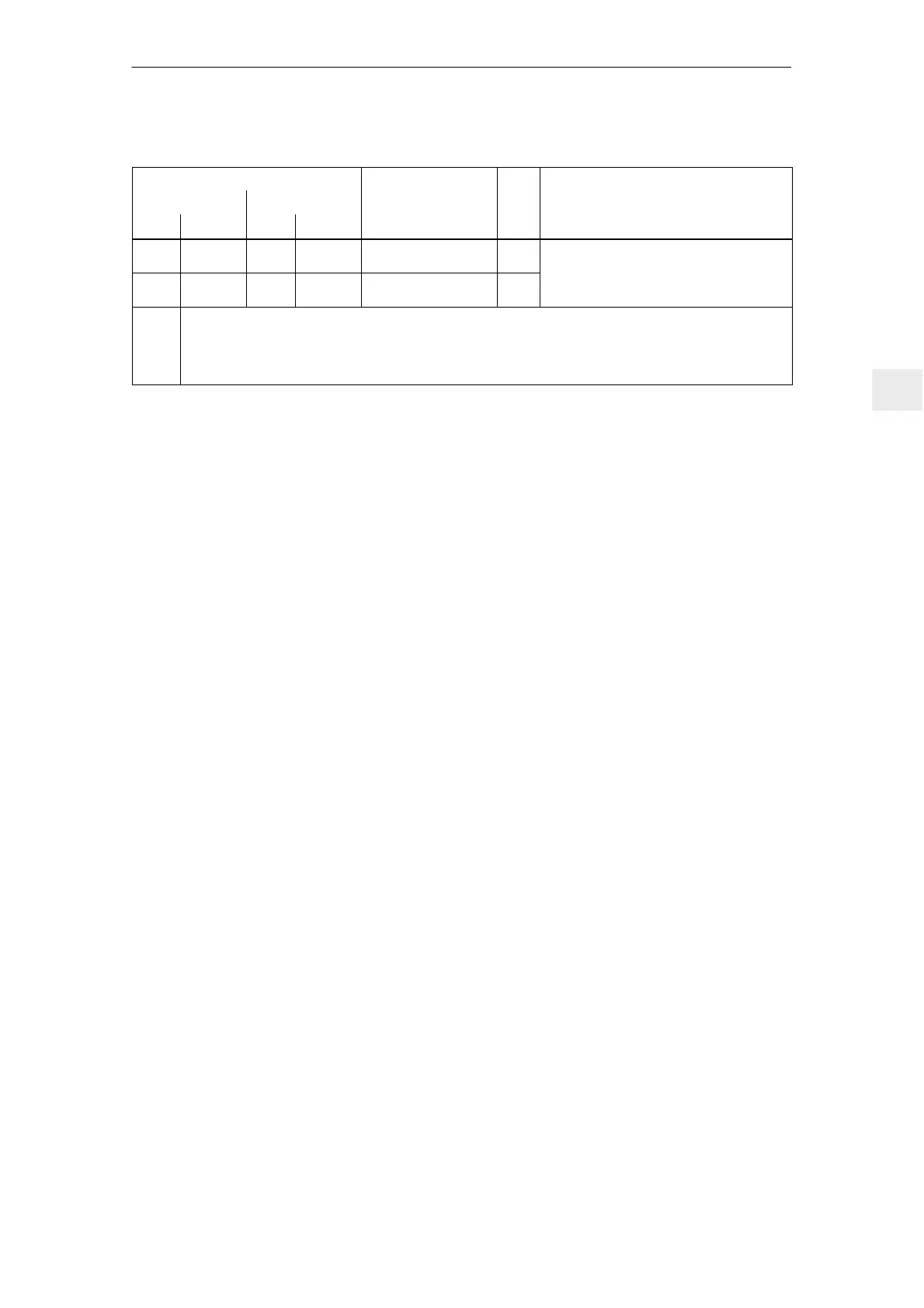

Table 5-20 Overview of the drive–specific terminals, continued

Terminal Technical dataType

1)

Function

Drive A

Technical dataType

1)

Function

Drive B

No.

Technical dataType

1)

Function

Desig.No.Desig.

O0.A X453.9 O0.B X454.9 Digital output 0

6)

DO Rated current per output: 500 mA

Maximum current per output: 600 mA

O1.A X453.10 O1.B X454.10 Digital output 1

6)

DO

Maximum current per output: 600 mA

Typical voltage drop: 250 mV for 500 mA

Short–circuit proof

Note:

S The power, switched via these outputs, is supplied via terminals P24 / M24 (X431). When dimensioning

the external supply, this must be taken into account.

S The digital outputs only ”function” if the external supply (+24 V, terminals P24/M24) is available.

1) AO: Analog output; I: Input; DI: Digital input; DO: Digital output; V: supply

2) Can be freely parameterized

3) The analog outputs (X441) should be connected via a terminal strip.

A shielded cable should be used for all of the analog outputs between X441 and the terminal strip. For this piece of cable,

the shield should be connected at both ends of the cable.

4 analog cables can then be fed from the terminal strip. The cable shields should be connected and the M cables should

be fed from a common M terminal.

4) Can be freely parameterized

All of the digital inputs are de–bounded per software. A delay time of between 1 and 2 interpolation clock cycles is obtained

due to the signal detection process (P1010).

5) I0.x is internally hardwired for position sensing where it acts almost instantaneously.

6) Can be freely parameterized

The digital outputs are updated in the interpolation clock cycle (P1010). A hardware–related delay time of approx. 200 µs

must be added.

5 Control Modules

Loading...

Loading...