3

05.01

3.5 Overview, position sensing

3-69

Siemens AG 2001 All rights reserved

SIMODRIVE 611 Planning Guide (PJU) – 05.01 Edition

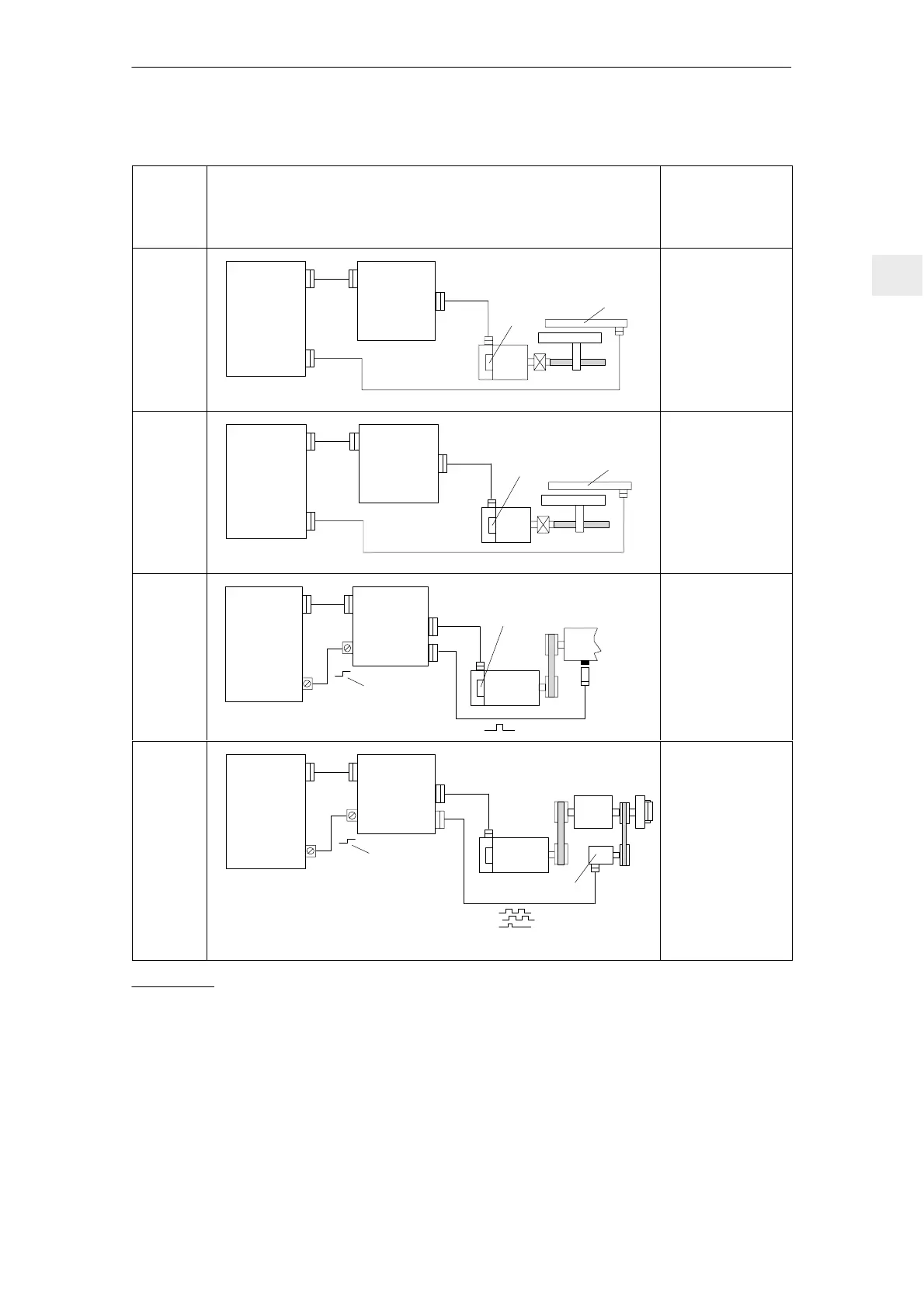

Table 3-4 Direct position sensing, analog controls

Control

board

version

Direct position sensing, analog controls

M: Max. possible

measuring steps

G: Encoder system

accuracy

Z: Pulse number

Resolver

control

with

standard

interface

Numerical

control

SIMODRIVE

drive

module

(analog)

Positioning with NC

n*

Resolver

Linear

measuring

system

l 50 m

1FK6

M and G are

dependent on the

accuracy of the

optional encoder

system and the

evaluation technique

in the NC

Feed

control

with

standard

and user–

friendly

interface

Tach. and RPS

Numerical

control

SIMODRIVE

drive

module

(analog)

Positioning with NC

n*

1FT5

Linear

measuring

system

l 50 m

M and G are

dependent on the

accuracy of the

optional encoder

system and the

evaluation technique

in the NC

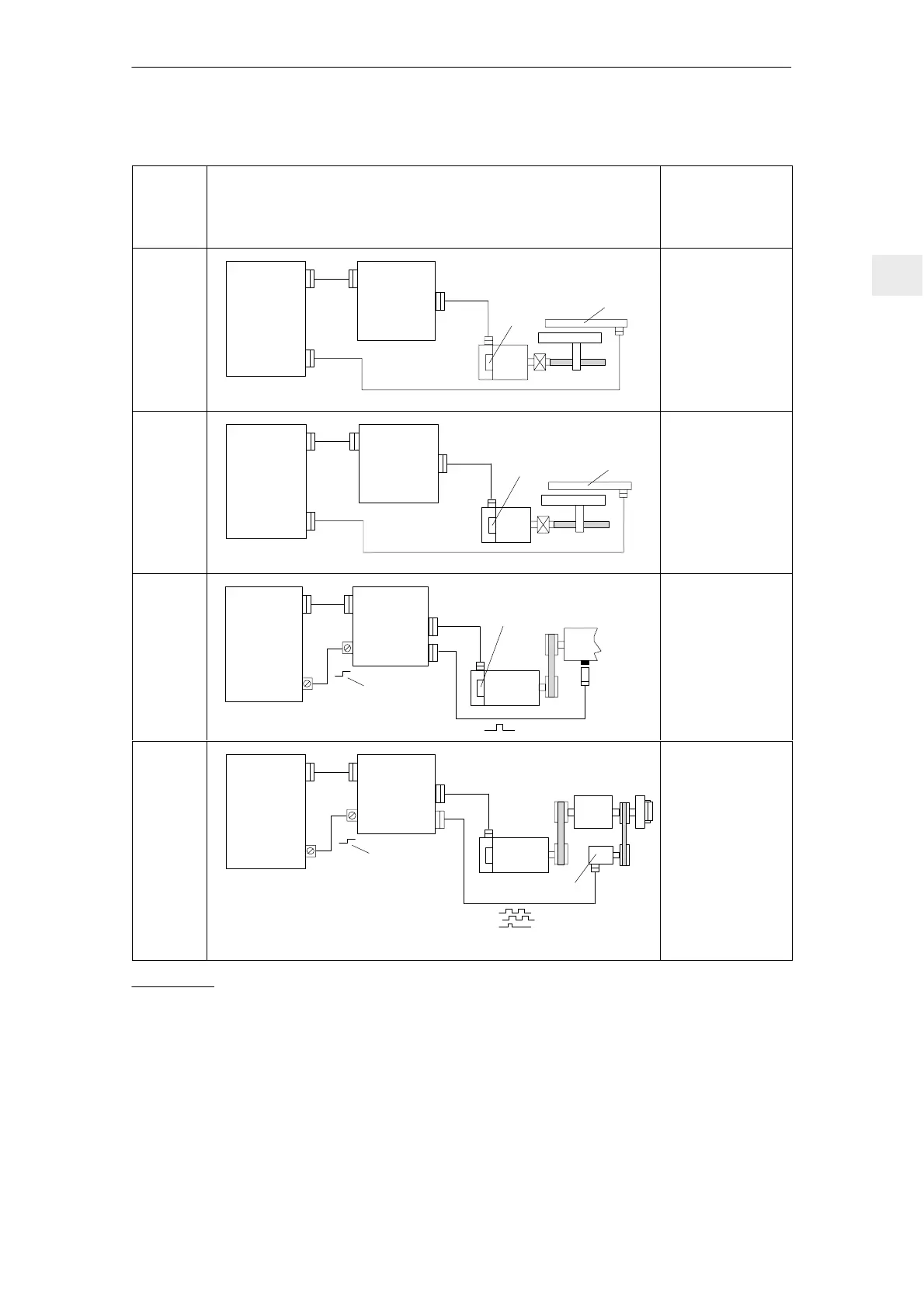

Main

spindle

control

with

analog

setpoint

inter–

face

Numerical

control

SIMODRIVE

drive

module

(analog)

Spindle positioning with drive

!Positioning command!

n*

1PH4/6/7

Incremental

BERO

l 50 m

X432

M = 2048 ⋅ Z

per 360 degrees

mech.

Z = 2048

G

Motor

encoder

=

" 0.006 degrees

G

BERO

=

1)

Main

spindle

control

with

analog

setpoint

inter–

face

and

input

spindle–

encoder

Spindle positioning with drive

Numerical

control

SIMODRIVE

drive

module

(analog)

!Positioning command!

n*

1PH4/6/7

Spindle encoder

l 50 m

M = Z ⋅ 4

per 360 degrees

mech.

G is dependent on

the accuracy of the

optional encoder

system.

1) The absolute accuracy when synchronizing with a BERO is a function of:

– the BERO switching time

– BERO hysteresis

– signal edge gradient of the BERO signal (dependent on the direction of rotation!) and the switching thresholds

in the drive; high >13 V, low < 5 V

– the search speed or the signal run times in the evaluation electronics

2) Distance–coded reference marks can be evaluated

3 Motor Selection, Position/Speed Sensing

Loading...

Loading...