CD600 Plus - User's Manual

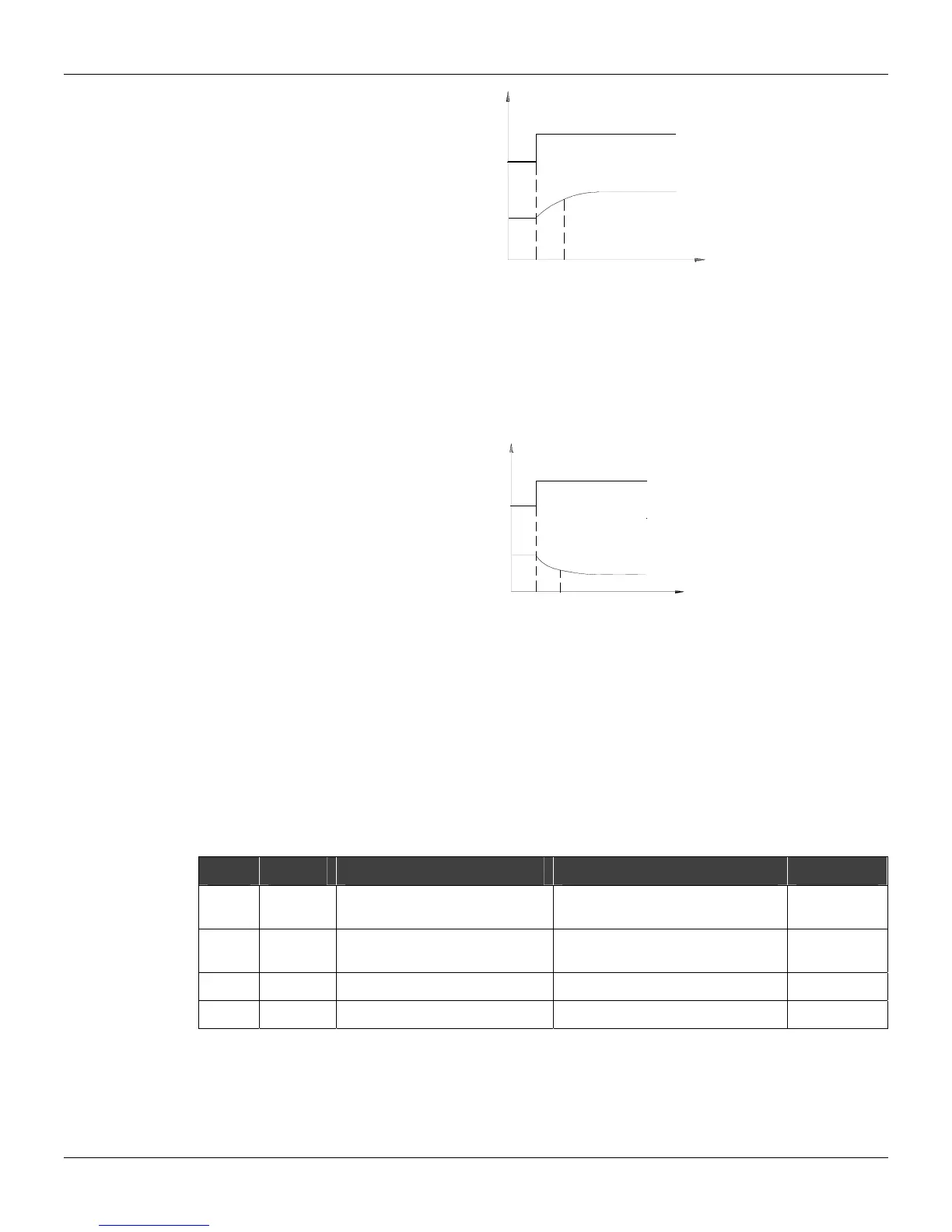

4.42

STEAM

FLOW

0t

t

1

TPUT

ERATURE

OU

TEMP

τ

1

- Time constant of the manipulated variable.

Fig 4.15.4 - Open loop response to a step change in steam flow rate (Manipulated Variable).

Note

: Time constant is the time required for the variable to reach 63.2% of the end value for a step

change.

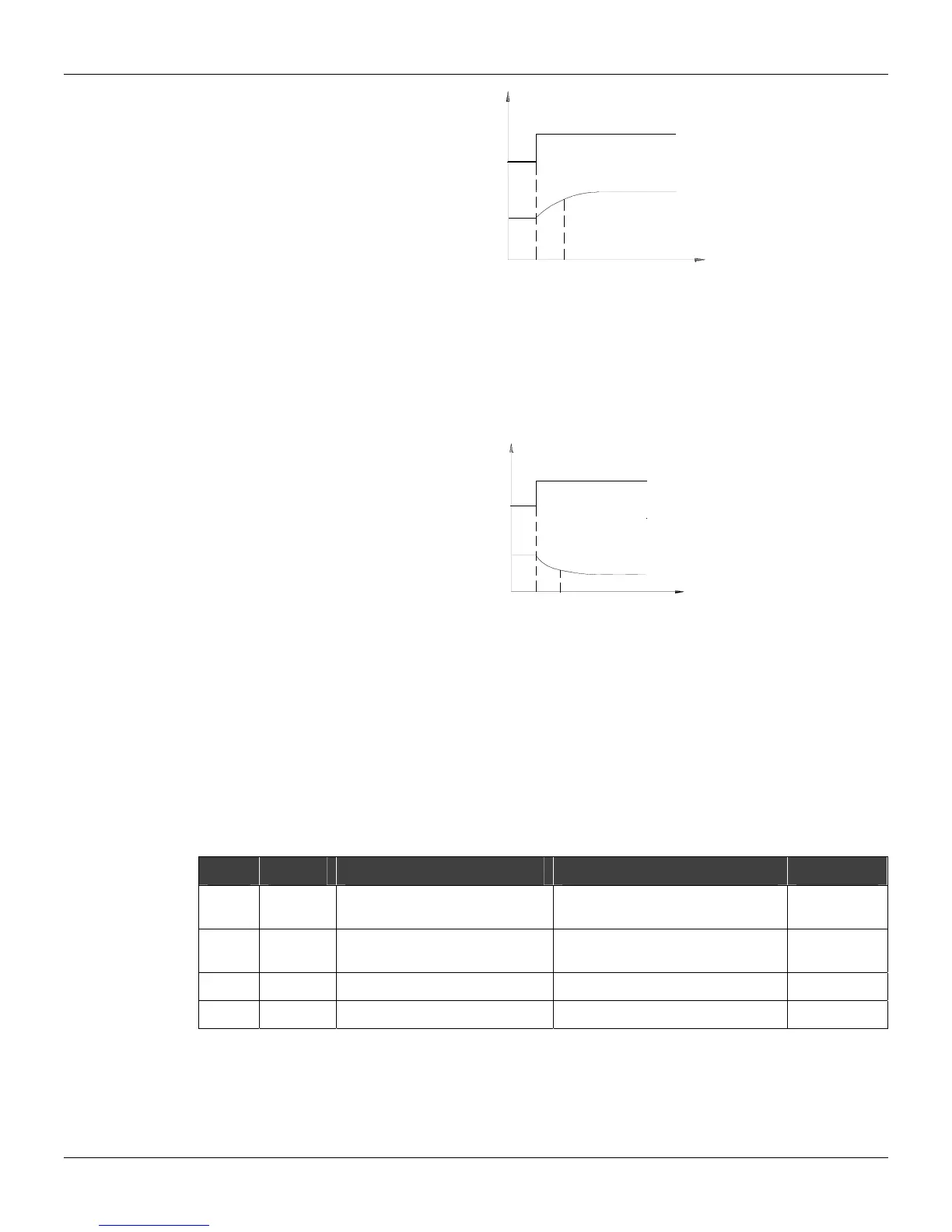

Figure 4.15.5 shows the response of the open loop system to a step variation in the load.

OUTPUT

TEMPERATURE

PRODUCT

FLOW

0

t

t

2

τ

2

- Time constant for a step variation in the product flow rate.

Fig 4.15.5 - Open loop response to a step variation in product flow rate (disturbance)

By comparing

τ

1

and τ

2

, it is possible to determine how the lead-lag block shall work:

- if

τ

1

>τ

2

the block should anticipate the disturbance signal (Lead)

- if

τ

1

<τ

2

the block should delay the disturbance signal (Lag)

The block may also be used to generate a first order Lag.

In this case, use

ATLE=0 and ATLA = desired time constant in the lead lag function.

TYPE MNEM DESCRIPTION RANGE DEFAULT

Address

I LIA Input A

0 to 170/225 to 240

0

I CDLL

Lead-Lag, time constant or

derivative

0 - Derivative

1 - Lead-Lag and time constant

1

P ATLE Lead time - Td (min.) 0.00 - 300.00 min. 0.00 min.

P ATLA Lag time - T (min.) 0.00 - 200.00 min. 0.00 min.

Number of Bytes per Type of Parameter: A = 4 C = 2 L = 2

Loading...

Loading...