Theory Of Operation Model 100E Instruction Manual

172 045150102 Rev XB1

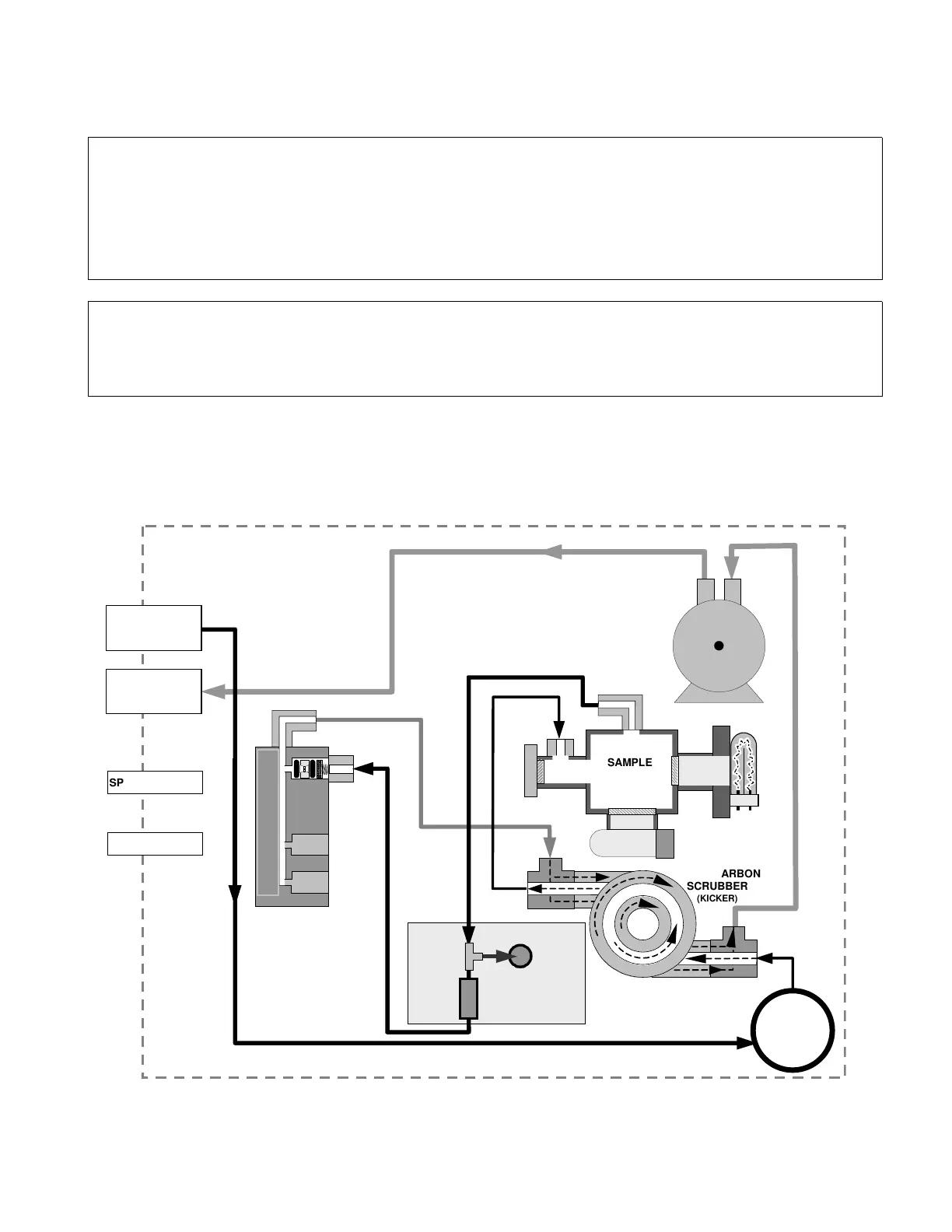

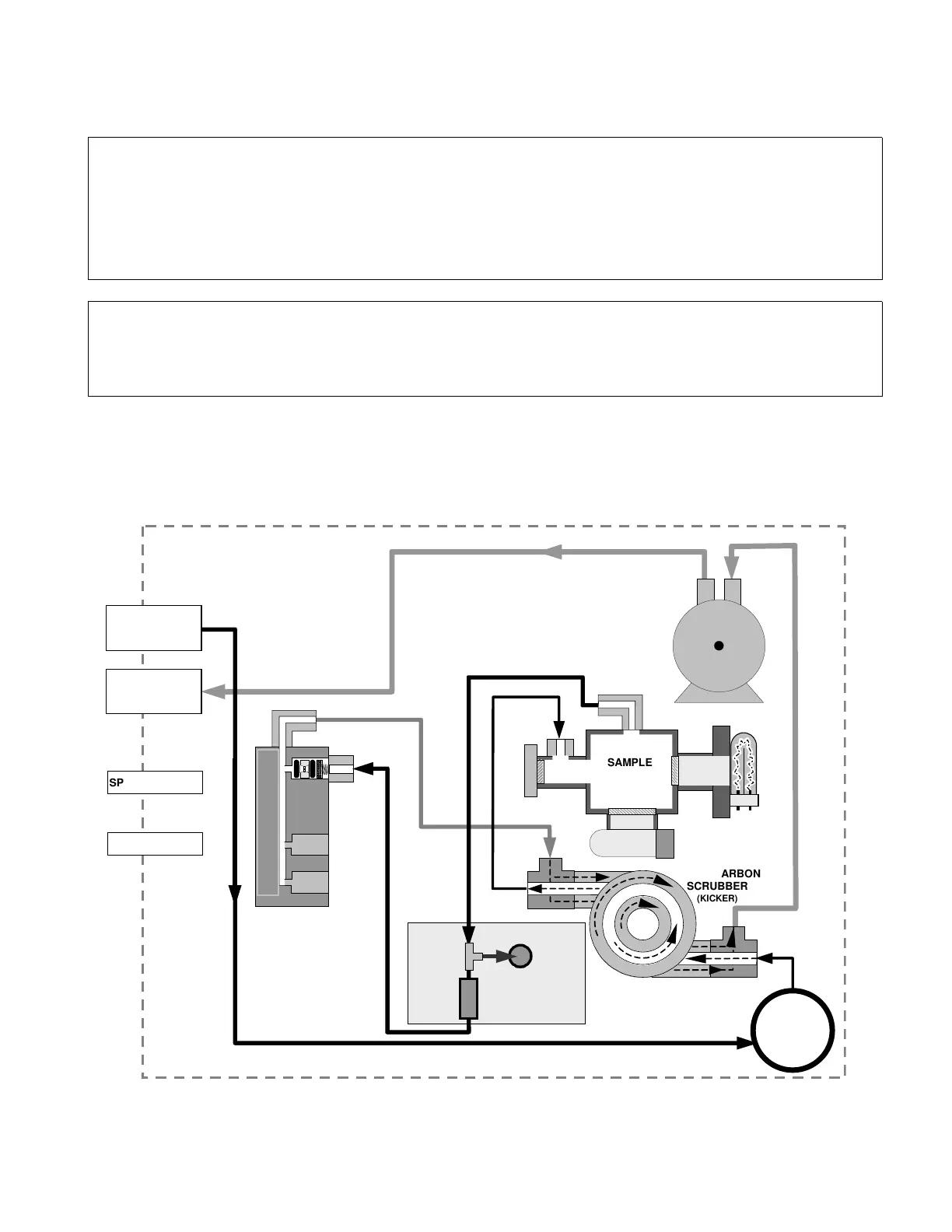

10.3. Pneumatic Operation

Caution

It is important that the sample airflow system is leak-tight and not pressurized

over ambient pressure. Regular leak checks should be performed on the

analyzer as described in the maintenance schedule, Table 9-1 . Procedures for

correctly performing leak checks can be found in Section 11.5.1.

Relative Pressure versus Absolute Pressure

In this manual vacuum readings are given in inches of mercury absolute pressure (in-

Hg-A), i.e. indicate an absolute pressure referenced against zero (a perfect vacuum).

10.3.1. Sample Gas Flow

The Flow of gas through the M100E UV Fluorescence SO2 Analyzer is created by a small

internal pump that pulls air though the instrument.

EXHAUST TO OUTER

LAYER OF KICKER

REACTION CELL PURGE

FLO

SENSOR

FLOW / PRESSURE

SENSOR PCA

SAMPLE

FILTER

INSTRUMENT CHASSIS

EXHAUST GAS

OUTLET

VACUUM MANIFOLD

SAMPLE GAS

INLET

KICKER EXHAUST TO PUMP

PUMP

FLOW

CONTROL

ASSY

SAMPLE

PRESSURE

SENSOR

UV

LAMP

PMT

SAMPLE

CHAMBER

HYDROCARBON

SCRUBBER

(KICKER)

SPAN GAS INLET

ZERO AIR INLET

Figure 10-7: M100 Gas Flow and Location of Critical Flow Orifice

Loading...

Loading...