X35 Monitor System Settings

4.22

31. Speed Source Fallback - indicates that the

GPS signal has been lost, and that Fallback

speed source is in use.

32. Cabin Keypad Not Communicating -

indicates lost communication with the cabin

keypad (switchbox).

33. Frame Keypad Not Communicating -

indicates lost communication with the frame

keypad (switchbox).

34. No Comms - Drill Fold ECU - indicates that

drill fold ECU is not communicating (only

used for 3420 machine).

35. Moving with QDA raised - indicates that the

QDA is raised while moving (only used for

3420 machine).

36. Implement Raised - indicates that the master

switch is ON with the secondary Tillage/

Implement/autoclutch switch OFF.

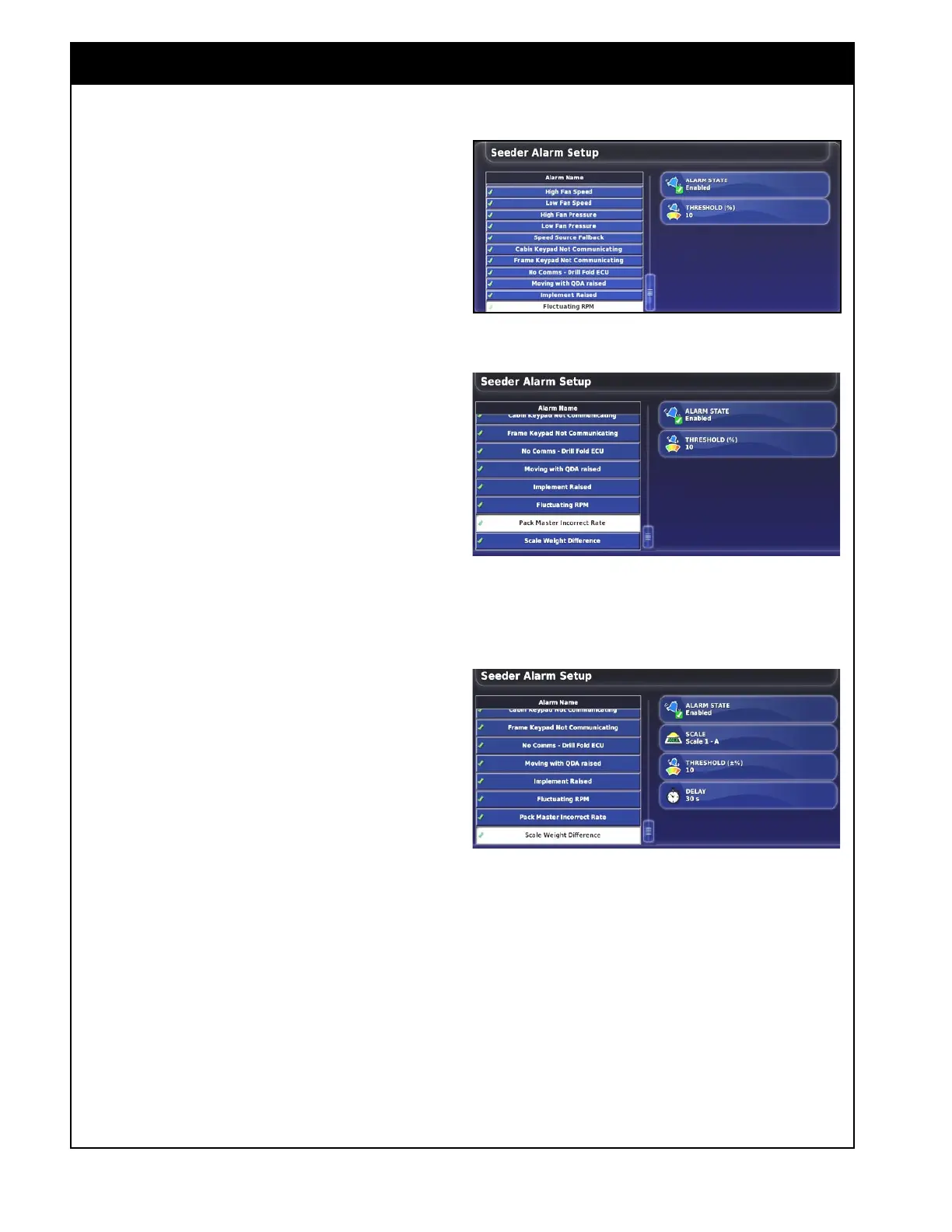

37. Fluctuating RPM - indicates that the granular

tank shaft rpm is fluctuating outside an

acceptable range. Can set the Threshold value

to alarm outside a certain range.

Refer to Section 12 - Troubleshooting.

38. Pack Master Incorrect Rate - indicates that

the actual Pack Master value is higher or lower

than the acceptable range.

a. Select the Threshold button to set a

percentage value that will be used to

calculate the upper and lower Pack Master

range limits.

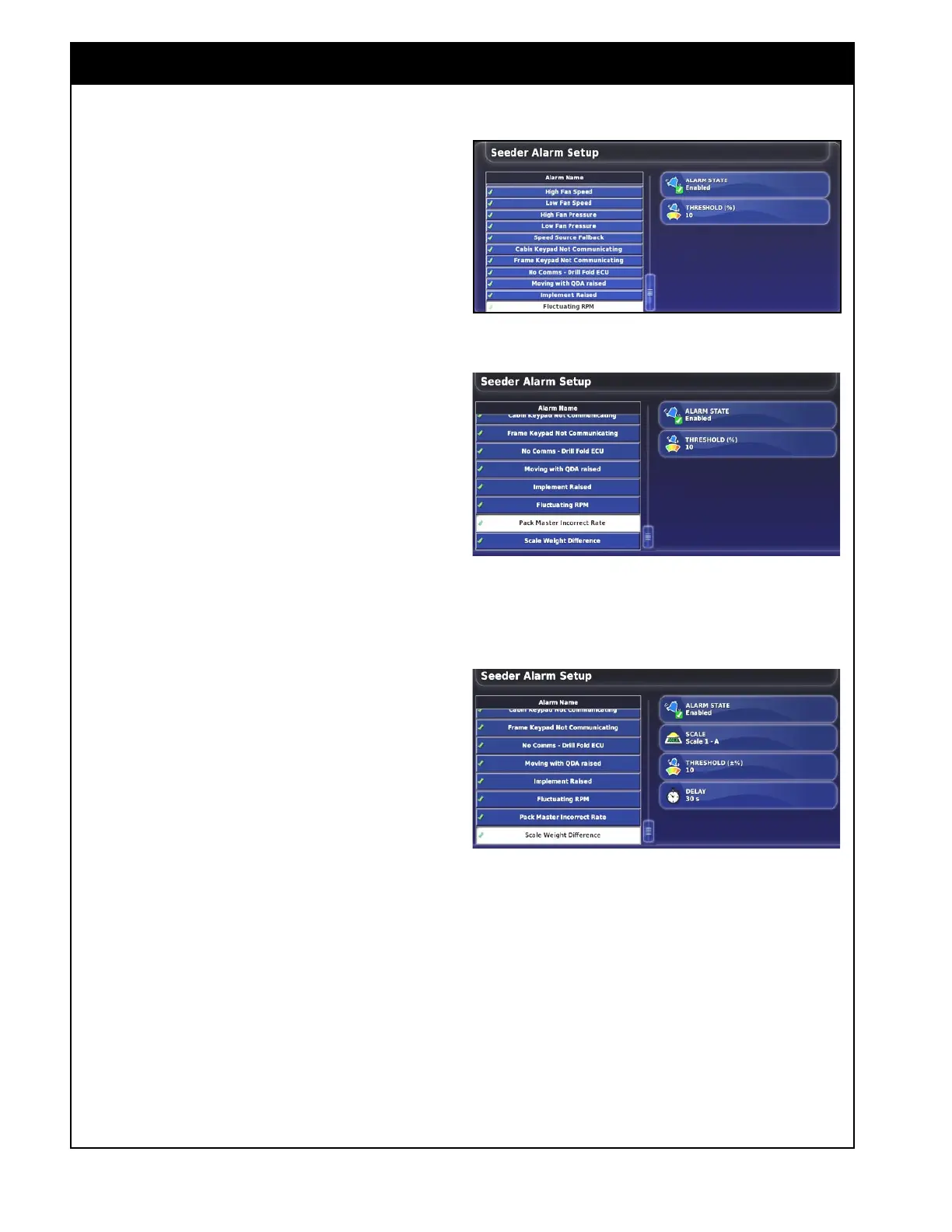

39. Scale Weight Difference - if the integrated

scale link option is installed this will indicate

if the measured weight change (actual) differs

from the theoretical weight change. Refer to

Section 12 - Troubleshooting.

a. Scale - change which scale you are setting

the parameters for.

b. Threshold - set the range to alarm outside

of.

c. Delay - set how long the threshold needs

to be exceeded before alarming.

Figure 4.26 - Fluctuating RPM Alarm

Figure 4.27 - Pack Master Incorrect Rate Alarm

Figure 4.28 - Scale Weight Difference Alarm

40. Scale Setup Number Mismatch - Indicates

if the X35 settings for the scale setup number

doesn’t match the actual Scale Link value for a

specific channel.

41. Scale Calibration Number Mismatch -

Indicates if the X35 settings for the scale

calibration number doesn’t match the actual

Scale Link value for a specific channel.

Loading...

Loading...