Chapter 10 Troubleshooting Alpha Compact 32708612

Version: 14.12.2012 page 129 of 135

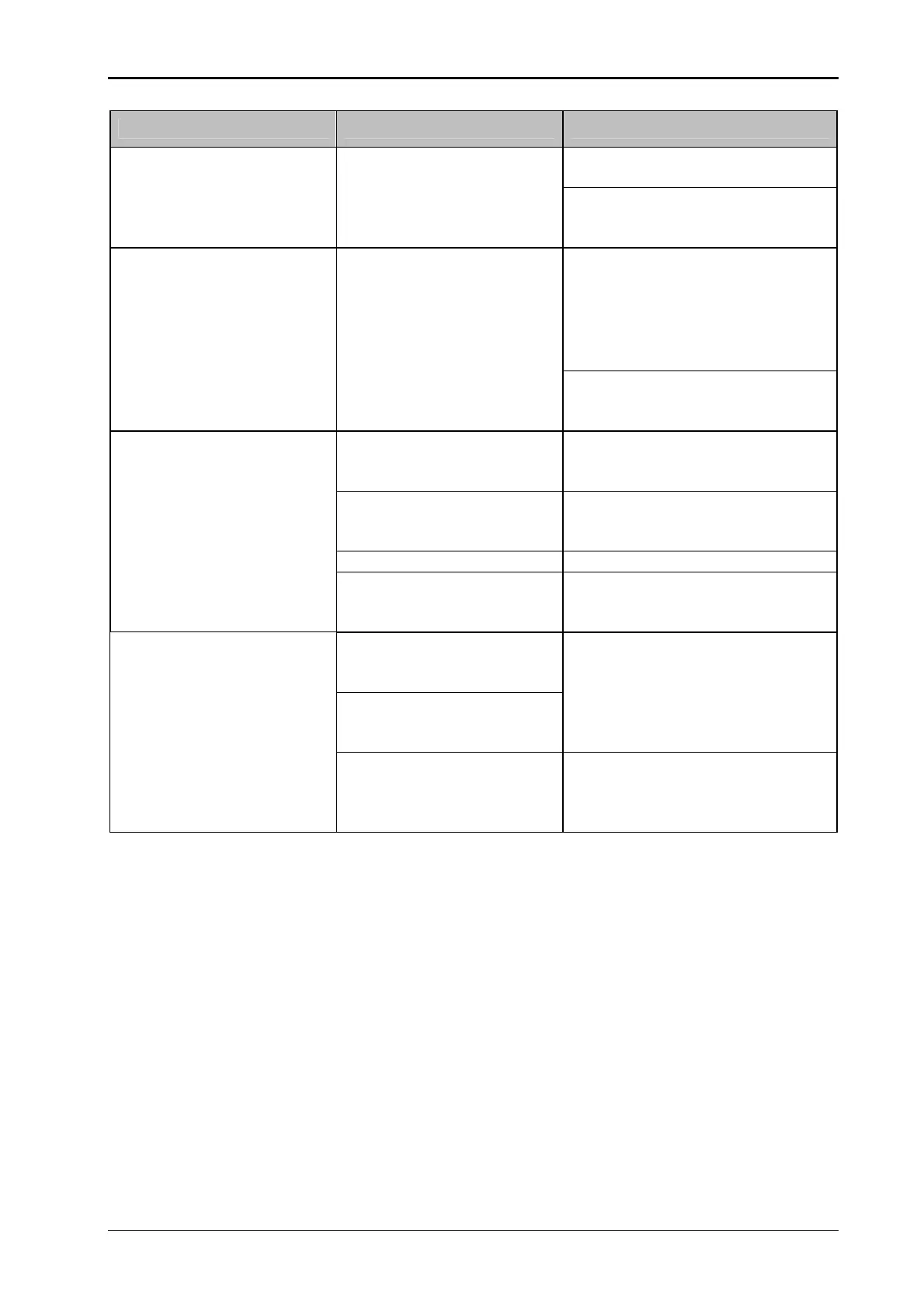

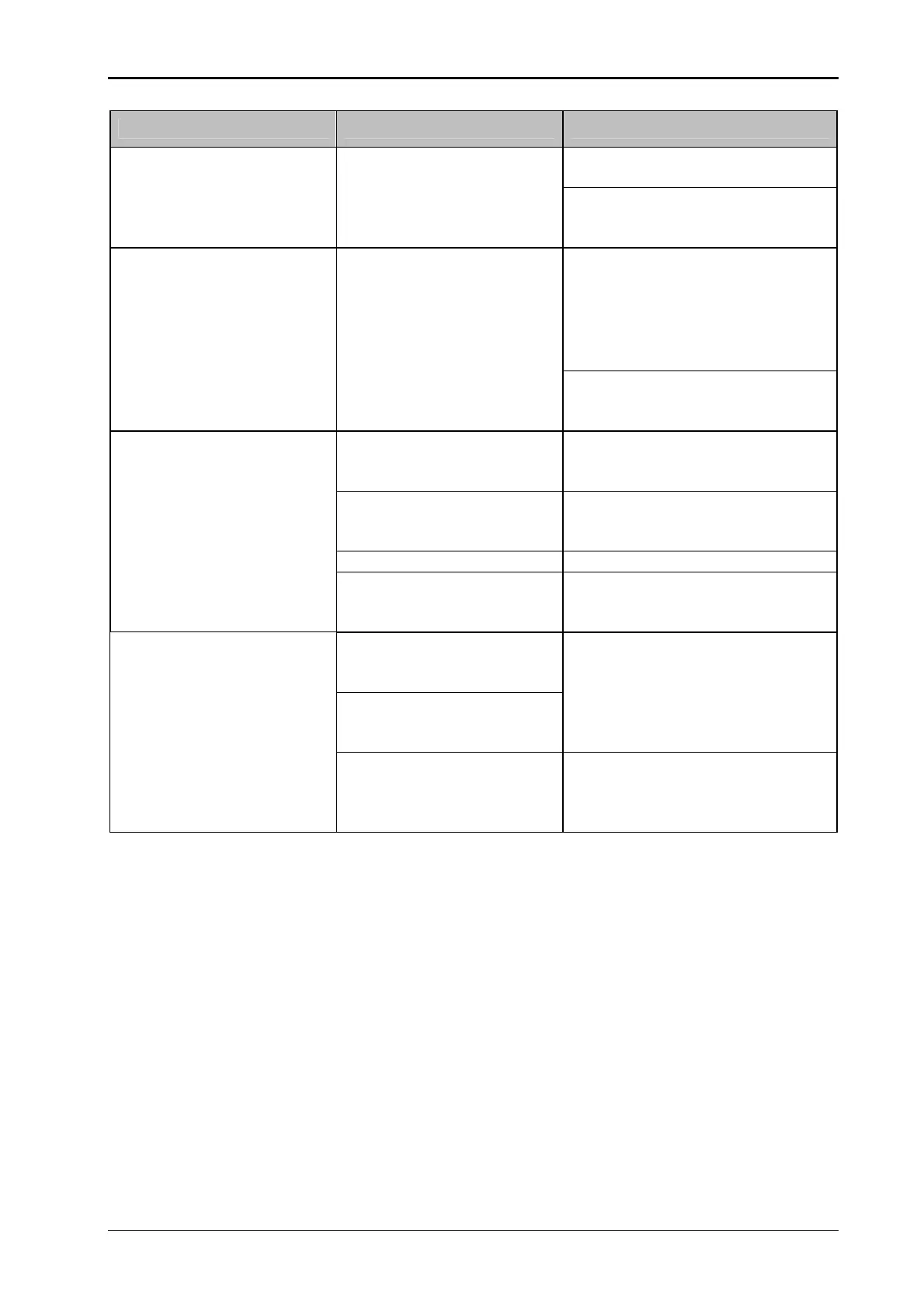

PROBLEM POSSIBLE CAUSE SOLUTION

Multiple labeling of the

product.

Start- or rather product-

trigger-signal is bouncing

(several impulses follow

the trigger-signal).

Sensor is defect and has to be

exchanged.

In case of PLC-triggering check

the outgoing signal and debounce

if necessary.

The label is not applied

(although the product

passed the start-light barri-

er).

No product detection. Please clean reflector or sensor if

they are polluted.

Check adjustment of product-

sensor (cp. manual of your sen-

sor) or exchange it.

The type of light barrier does not

suit for the product because it`s

transparent or reflective…

The desired rate of appli-

cation cannot be reached

with the labeler.

The required rate of appli-

cation from the conveyor

exceeds the specifications.

Check the system data consider-

ing the used label size. Reduce

product speed if necessary.

Incorrect configuration pa-

rameter values of the la-

beler.

Check setup of the labeler.

Slip at shaft encoder. Check mechanical setup.

[V-LABEL] is set too low

also when using a shaft

encoder.

Check the adjustment of speed-

synchronization.

Labeler applies without

evident reason.

Start-light barrier and/or

product-sensor and/or re-

flector are loose or vibrate.

Check adjustment of the sensor

(cp. manual of your sensor).

Start- /product sensor and

reflector are not adjusted

or misaligned.

Loose cable-connections. Check all connections with the

controller or inquire a Service

Technician at the Service-

Hotline

Loading...

Loading...