Maintenance

1203−1/A1

Winterthur Gas & Diesel Ltd.

1/ 2

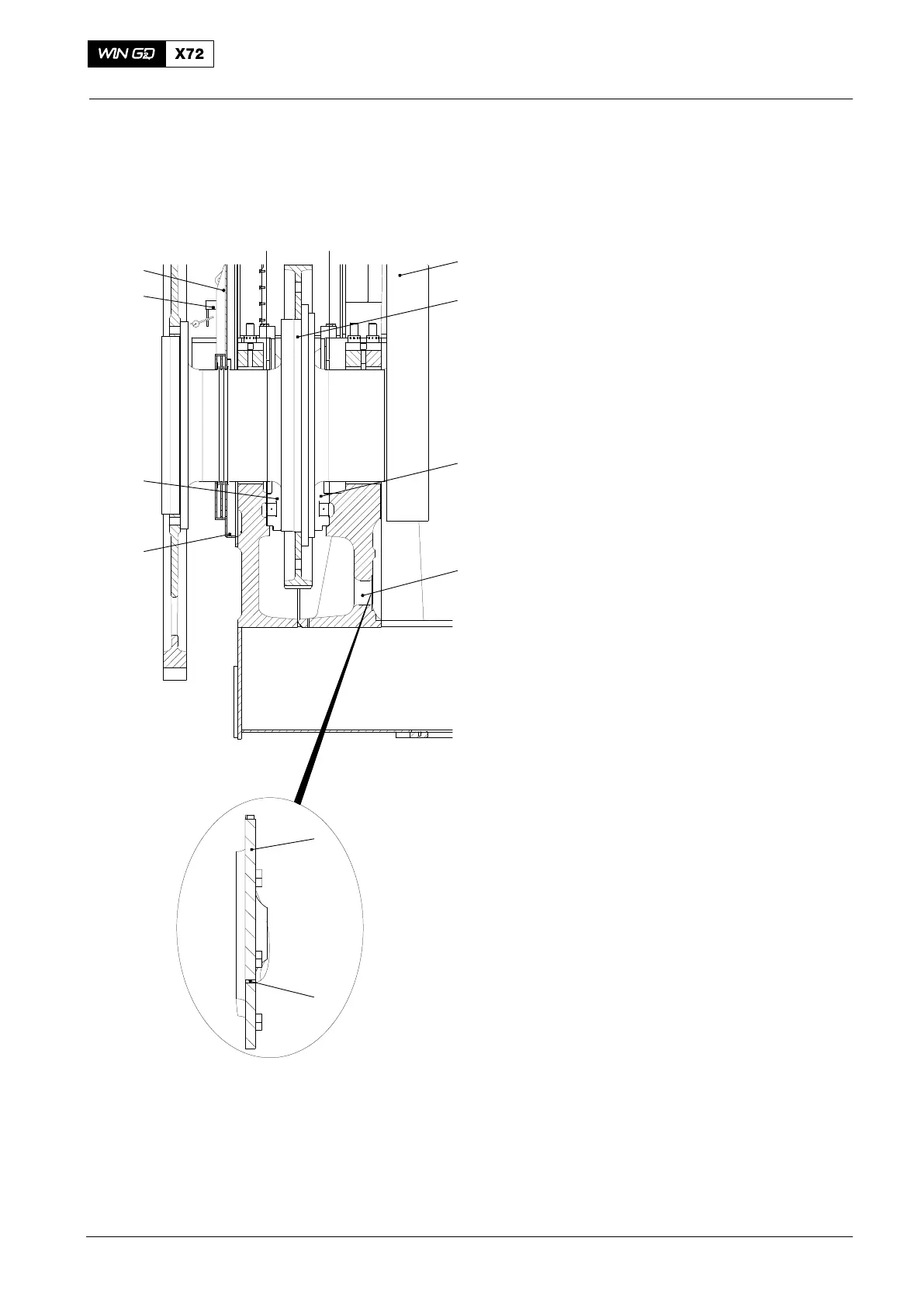

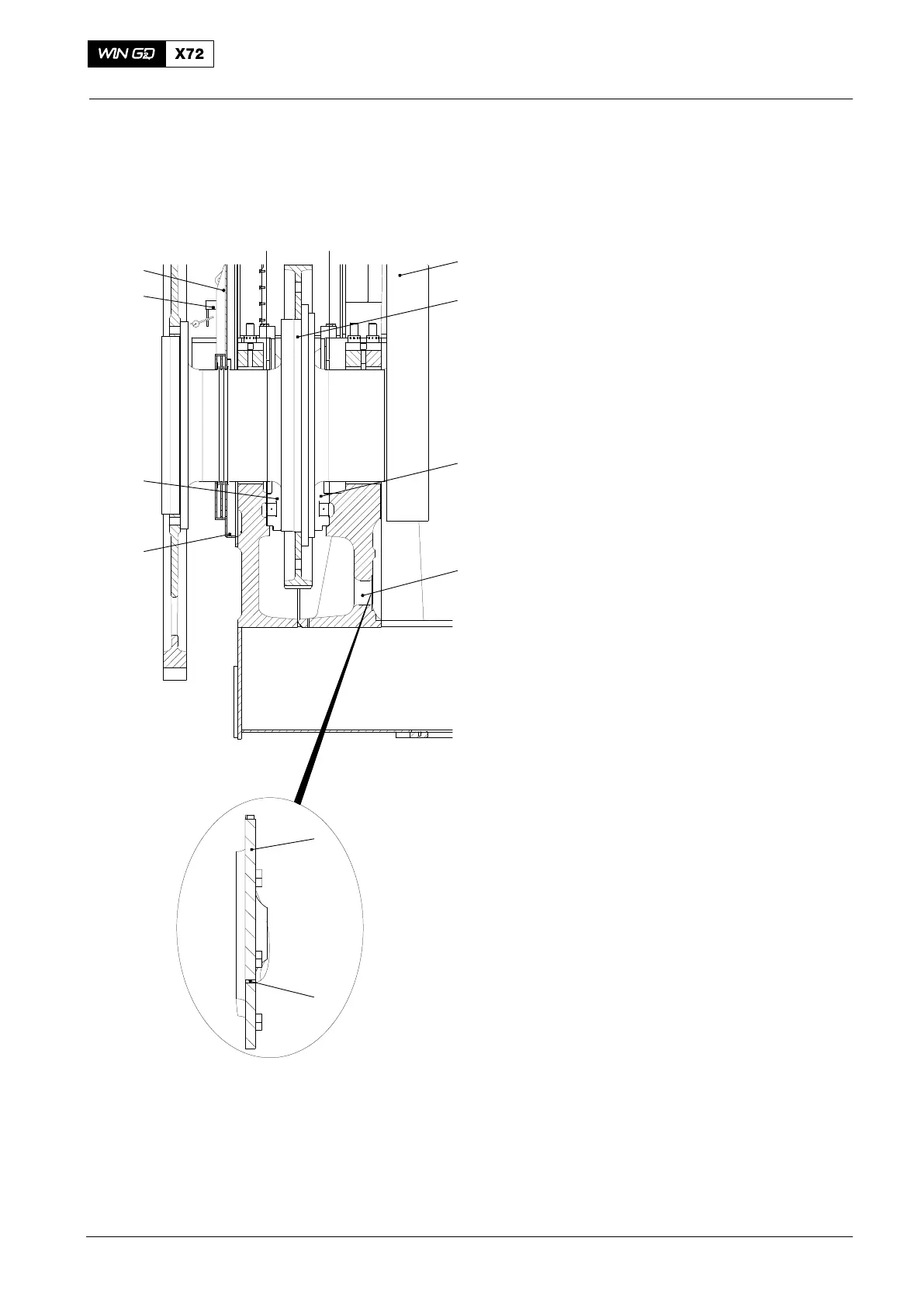

Axial Clearance Check

Tools:

1 Inside micrometer 94101

1. Procedure One

1) Start the engine in the direction AHEAD

to move the crankshaft fully forward.

2) Stop the engine.

3) Put the dial gauge 8 in position on the

oil baffle (top part) (9, Fig. 1) and

record the value.

4) Remove the dial gauge (8).

5) Start the engine in the direction

REVERSE to move the crankshaft fully

rearward.

6) Stop the engine.

7) Put the dial gauge (8) in position on the

oil baffle (top part) (9) and record the

value.

8) Remove the dial gauge (8).

9) Compare the values with those given in

the engine documents on the Check

Dimensions page (see also the 0330−1

Clearance Table, Crankshaft and

Thrust Bearing).

If the measured values are more than the

nominal values given, the thrust pads are

worn.

10) After maintenance on the area of the

thrust bearing, do as follows:

11) Remove the cover (4).

12) Do a check of the thrust bearing

housing.

13) If necessary, remove particles from the

area (11).

14) Install the cover (4).

15) Each 6000 to 8000 operation hours,

make sure that the opening (5) is clear.

2015

Thrust Bearing

6

7

2

3

8

9

1

WCH02338

4

5

11

Fig. 1

Loading...

Loading...