Maintenance2138−1/A2

Winterthur Gas & Diesel Ltd.

4/ 5

4.3 Installation

CAUTION

Damage Hazard: The surfaces of the cylinder liner and the nozzle

tip make a metallic seal. The seat angles in the cylinder liner and

on the nozzle tip are different. Do not use a gasket between the

cylinder liner and the nozzle tip, or damage to the equipment can

occur.

Note: When you install the lubricating quill, replace all components.

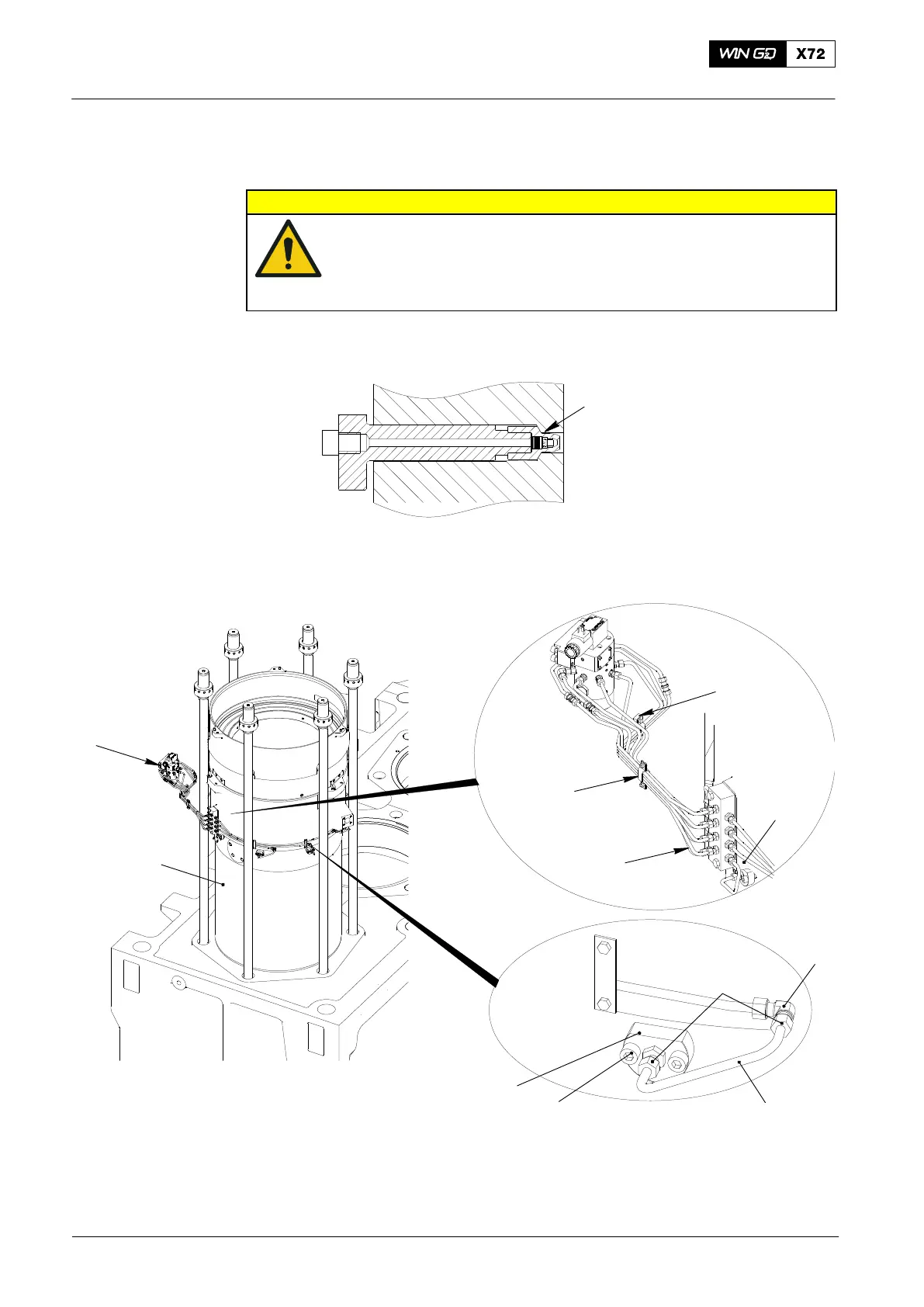

1) Make sure that the sealing surfaces (SS, Fig. 4) are clean and have no damage.

SS

WCH03216

Fig. 4

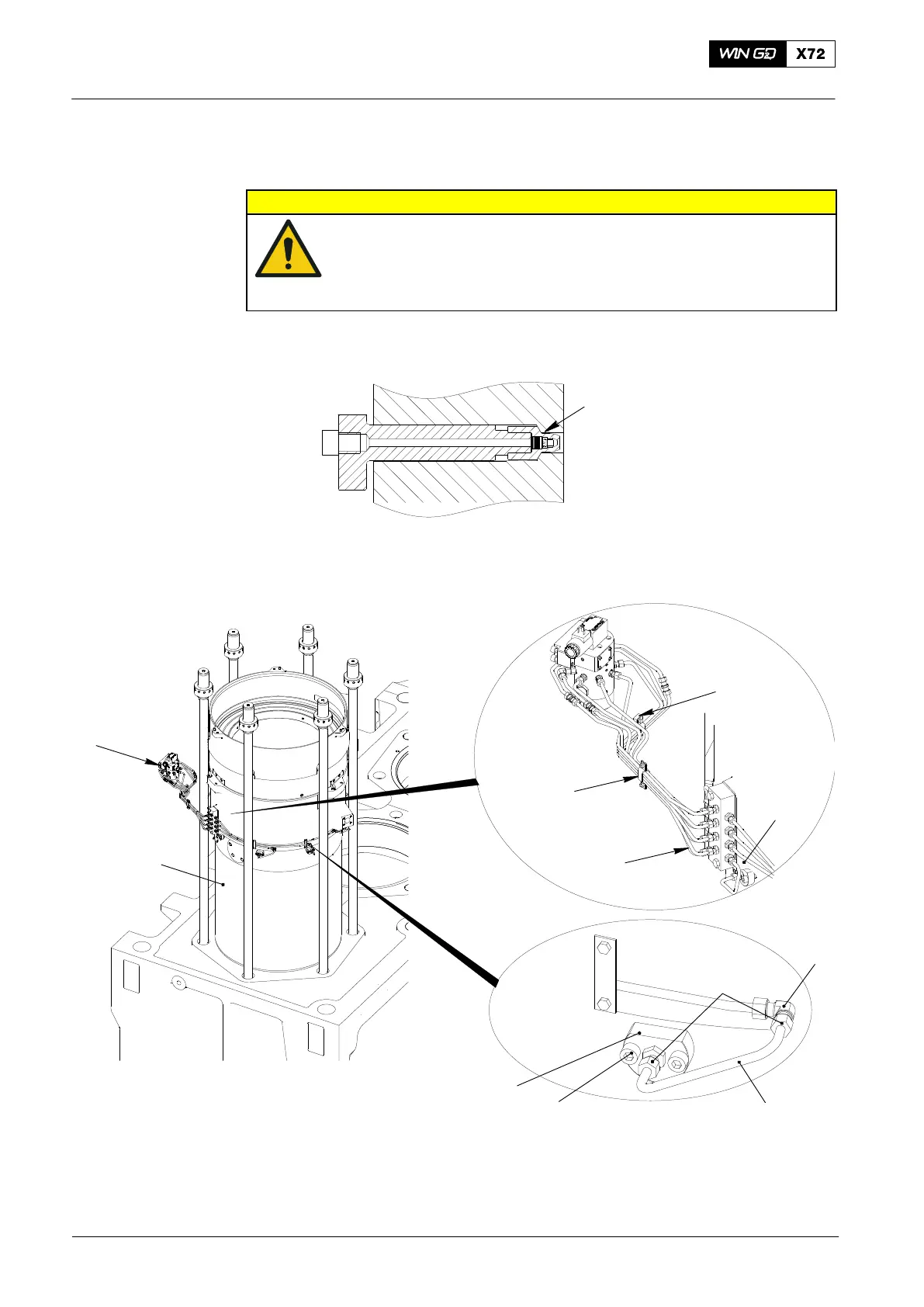

2) Apply oil to the threads of the two screws (8, Fig. 5).

3) Put the lubricating quill (9) in position.

WCH02268

2

FREE END

1

7

8

9

10

3

4

5

3

Fig. 5

6

4) Torque the screws (8) to 10 Nm.

5) Remove the plugs from the oil pipes (6, 7).

6) Connect the oil pipe (7) to the lubricating quill (9) and the pipe (6).

2015

Lubricating Quill

Loading...

Loading...