Maintenance

3403−1/A1

Winterthur Gas & Diesel Ltd.

5/ 6

WARNING

Injury Hazard: You must

put on safety goggles and

gloves when you do work

on hot components. Oil

can come out as a spray

and cause injury.

17) Do a function check of the cylinder

lubricating system. See 7218−1,

paragraph 1.2.

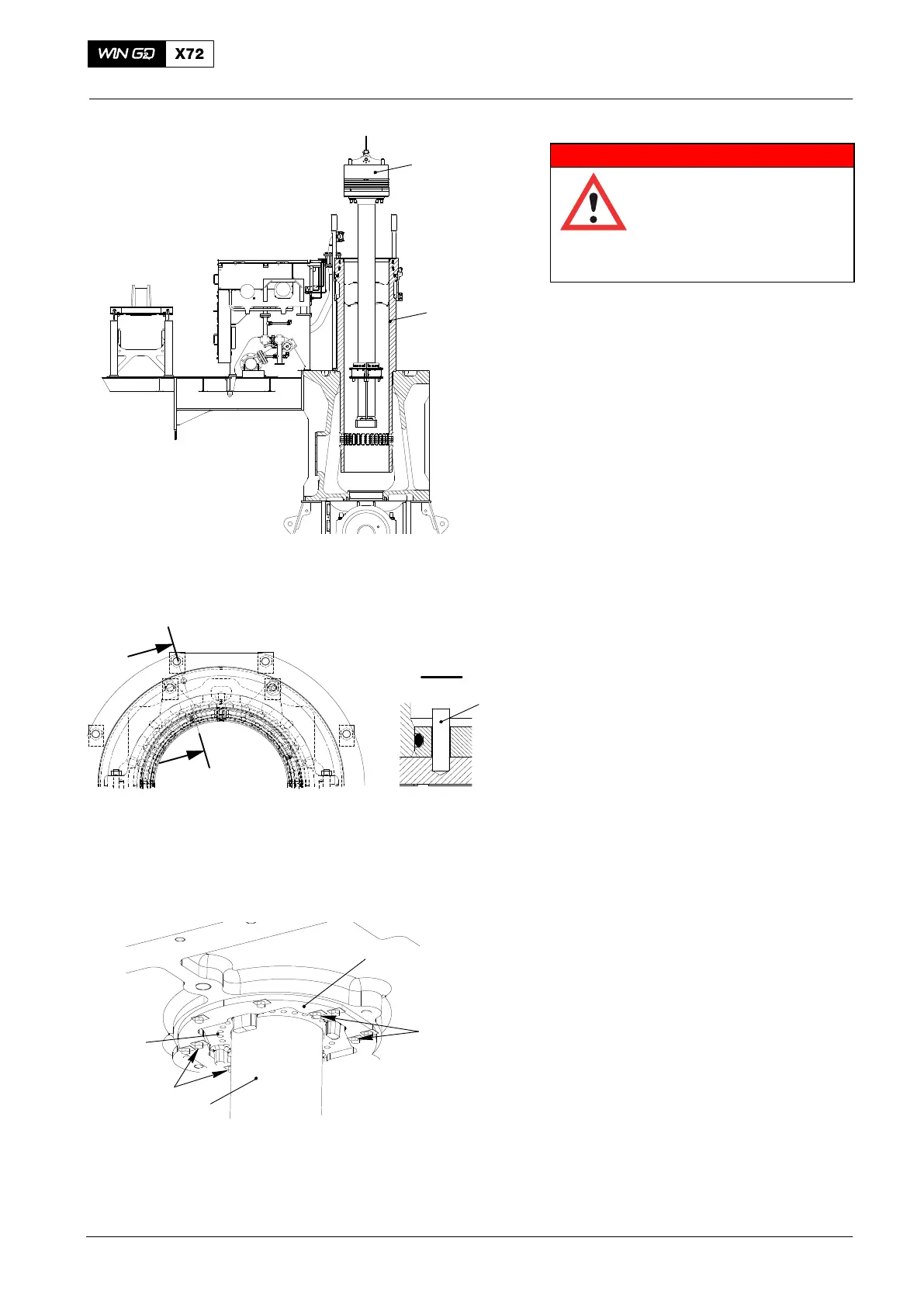

18) Carefully lower the piston (1, Fig.10)

into the cylinder liner (2).

19) Use the turning gear to turn the crank

to BDC.

20) Make sure that the piston rod gland is

in the correct position for the dowel pin

(1, Fig. 11) to align with the crosshead.

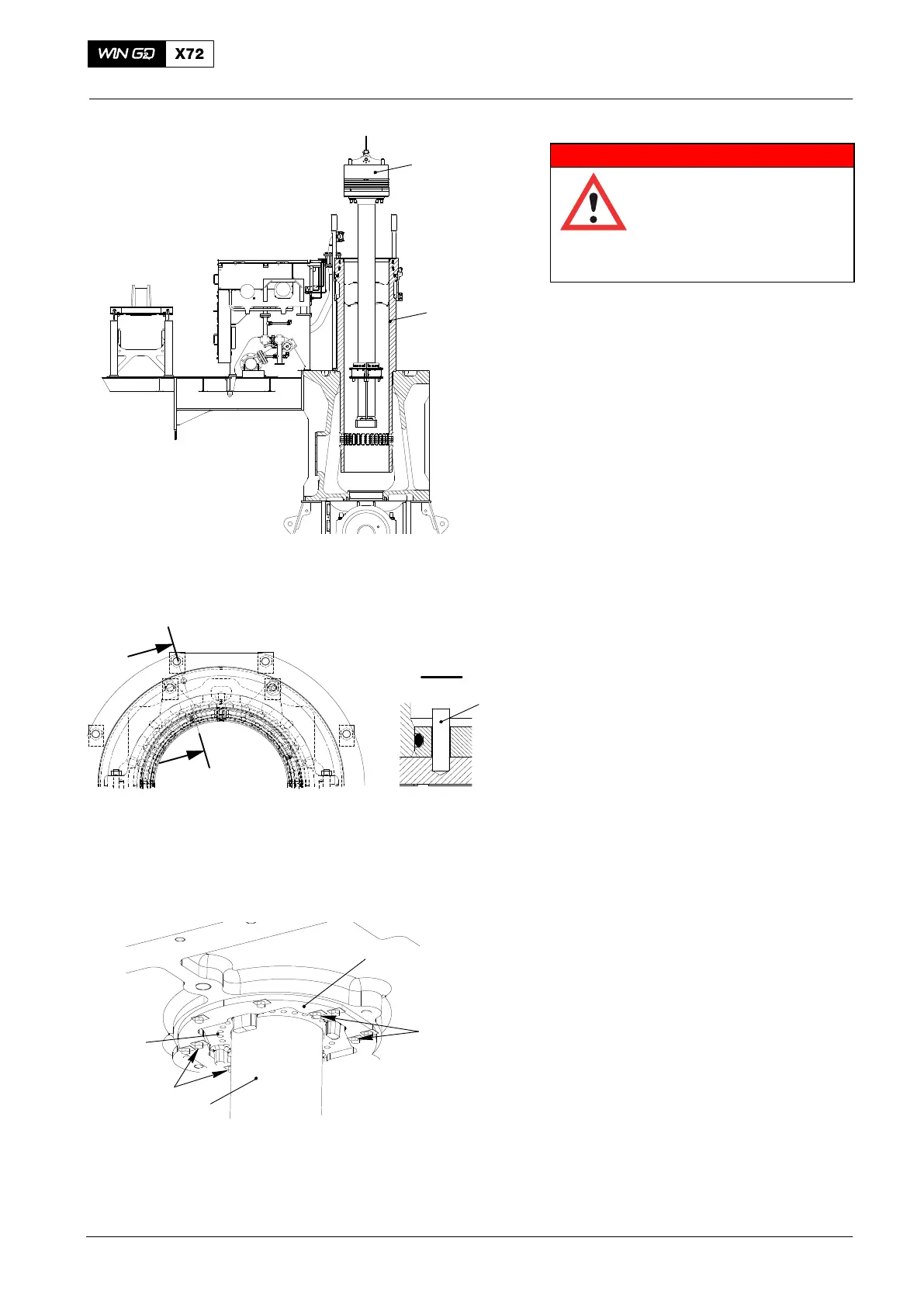

21) Put oil on the four bolts (2, Fig.12).

22) Attach the piston rod gland (4) to the

cylinder block with the four bolts (2)

and new locking plates.

23) Torque the four bolts (2) to 150 Nm.

24) Bend the locking plates to lock the

bolts (2).

25) Remove the insertion funnel (94342)

from the cylinder liner.

2015

Piston: Removal and Installation

WCH02609

1

2

Note: Some parts

can look different

WCH02292

I

I

1

I - I

Fig. 10

Fig. 11

WCH02435

1

2

2

3

Fig. 12

4

Loading...

Loading...