CYLINDERS AND PISTONS

5-35

b. If out of specification, rebore or replace the

cylinder, and replace the piston and piston

rings as a set.

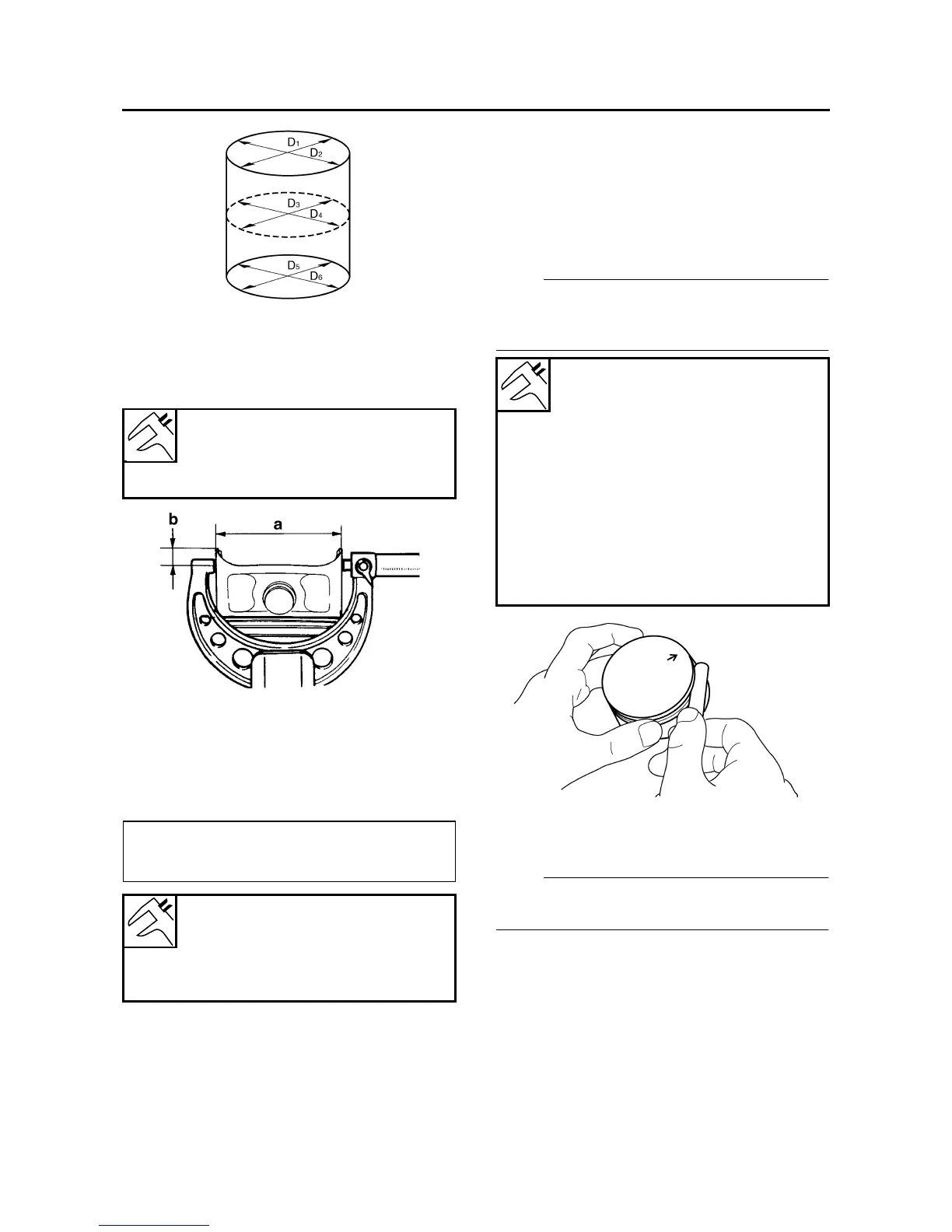

c. Measure the piston skirt diameter “D” “a” with

the micrometer.

d. If out of specification, replace the piston and

piston rings as a set.

e. Calculate the piston-to-cylinder clearance

with the following formula.

f. If out of specification, rebore or replace the

cylinder, and replace the piston and piston

rings as a set.

▲▲▲▲▲▲▲▲▲ ▲ ▲▲▲▲▲▲▲▲▲ ▲ ▲▲▲▲ ▲ ▲▲▲▲ ▲▲▲

EAS24430

CHECKING THE PISTON RINGS

The following procedure applies to all of the pis-

ton rings.

1. Measure:

• Piston ring side clearance

Out of specification → Replace the piston

and piston rings as a set.

NOTE:

Before measuring the piston ring side clearance,

eliminate any carbon deposits from the piston

ring grooves and piston rings.

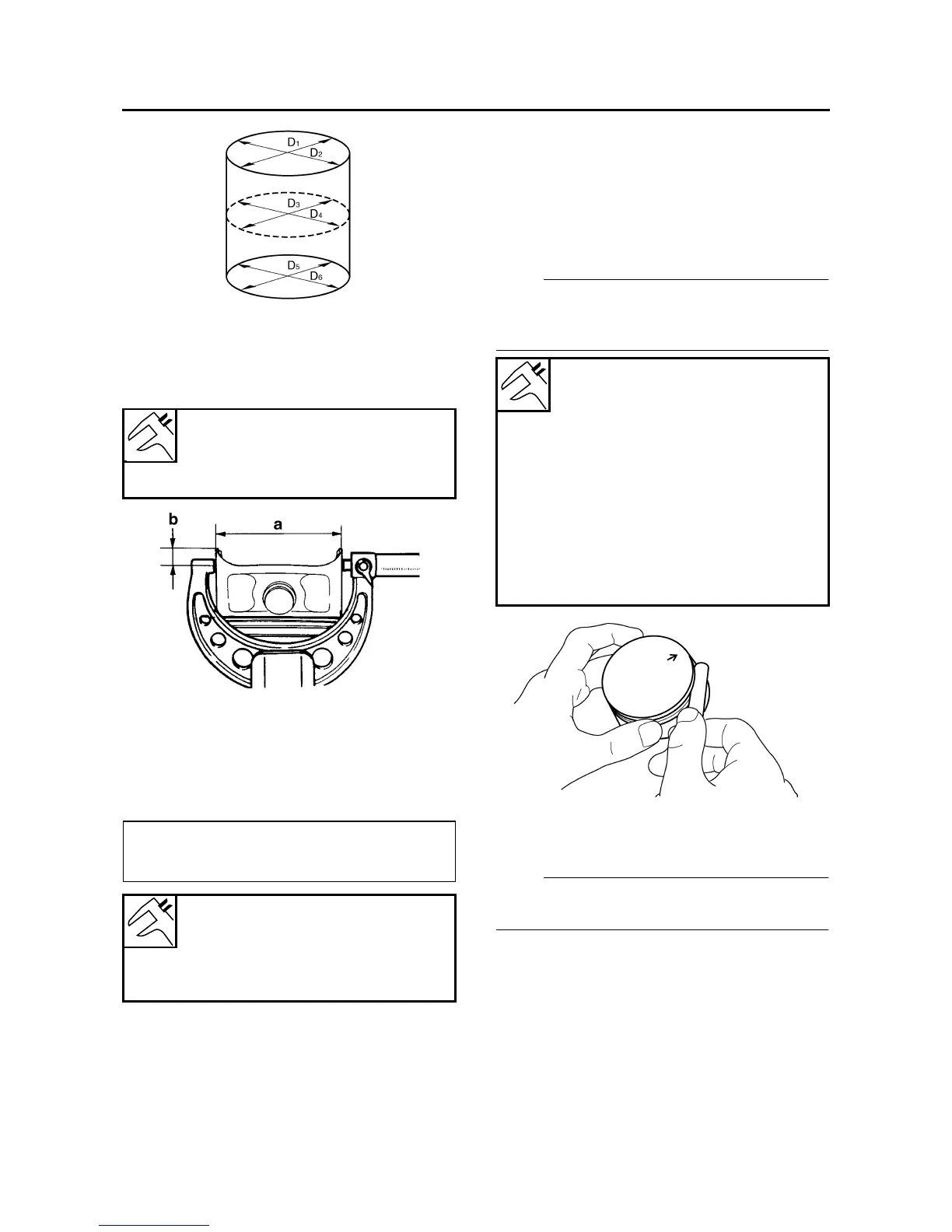

2. Install:

• Piston ring

(into the cylinder)

NOTE:

Level the piston ring in the cylinder with the pis-

ton crown.

Piston

Diameter D

99.955–99.970 mm (3.9352–

3.9358 in)

b. 8 mm (0.31 in) from the bottom edge of the

piston

• Piston-to-cylinder clearance =

Cylinder bore “C” -

Piston skirt diameter “P”

Piston-to-cylinder clearance

0.030–0.055 mm (0.0012–0.0022

in)

Limit

0.15 mm (0.0059 in)

Piston ring

Top ring

Ring side clearance

0.030–0.080 mm (0.0012–

0.0032 in)

Limit

0.130 mm (0.0051 in)

2nd ring

Ring side clearance

0.030–0.070 mm (0.0012–

0.0028 in)

Limit

0.130 mm (0.0051 in)

Loading...

Loading...