CRANKSHAFT

5-76

NOTE:

• Do not move the connecting rod or crankshaft

until the clearance measurement has been

completed.

• Lubricate the bolts threads and nut seats with

molybdenum disulfide grease.

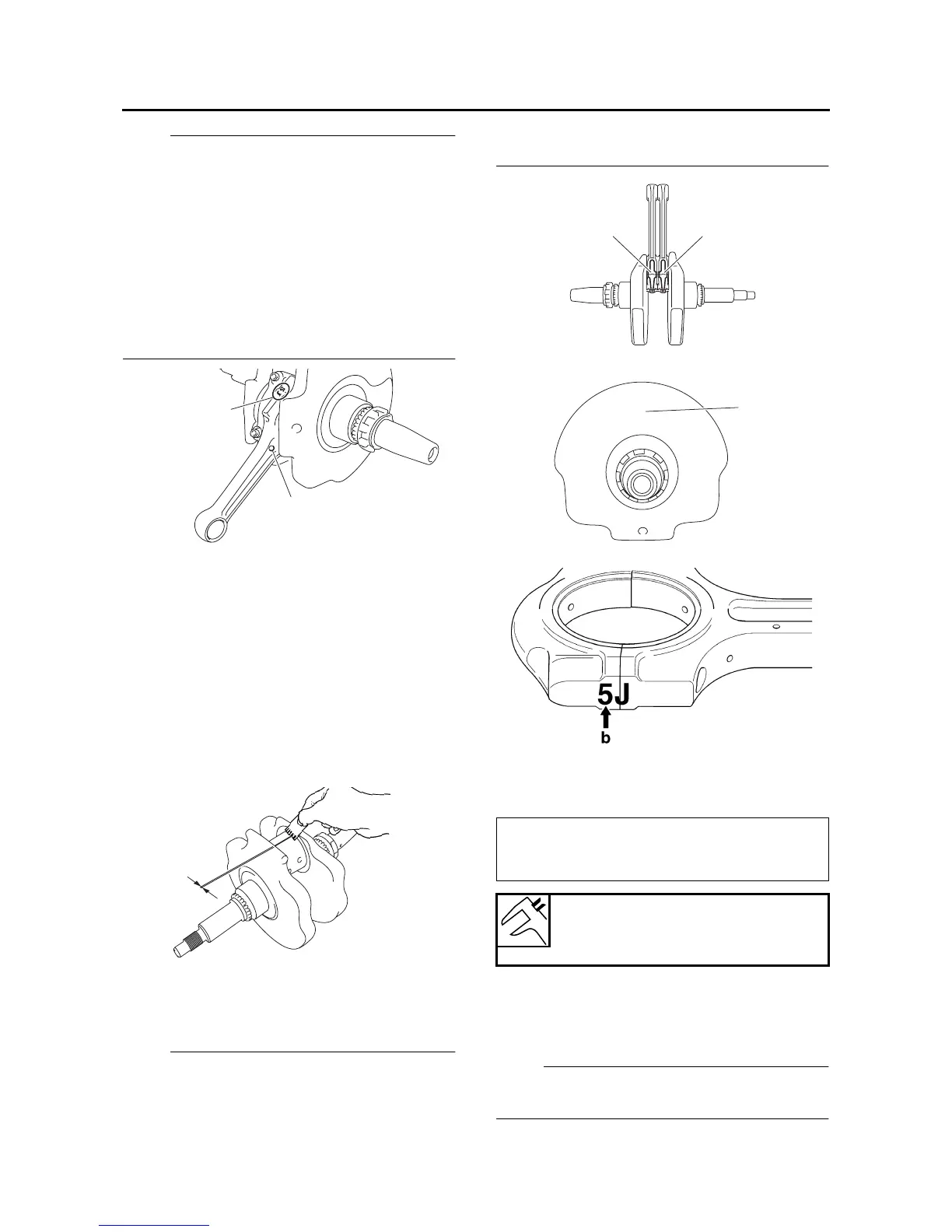

• Make sure the projection “c” on the connecting

rod faces towards the left side of the crank-

shaft.

• Make sure the characters “d” on both the con-

necting rod and connecting rod cap are

aligned.

e. Tighten the connecting rod bolts.

Refer to “INSTALLING THE CONNECTING

RODS” on page 5-77.

f. Remove the connecting rod and big end

bearings.

Refer to “REMOVING THE CONNECTING

RODS” on page 5-75.

g. Measure the compressed Plastigauge®

width “e” on the crankshaft pin.

If the crankshaft-pin-to-big-end-bearing

clearance is out of specification, select re-

placement big end bearings.

▲▲▲▲▲▲▲▲▲ ▲ ▲▲▲▲▲▲▲▲▲ ▲ ▲▲▲▲ ▲ ▲▲▲▲ ▲▲▲

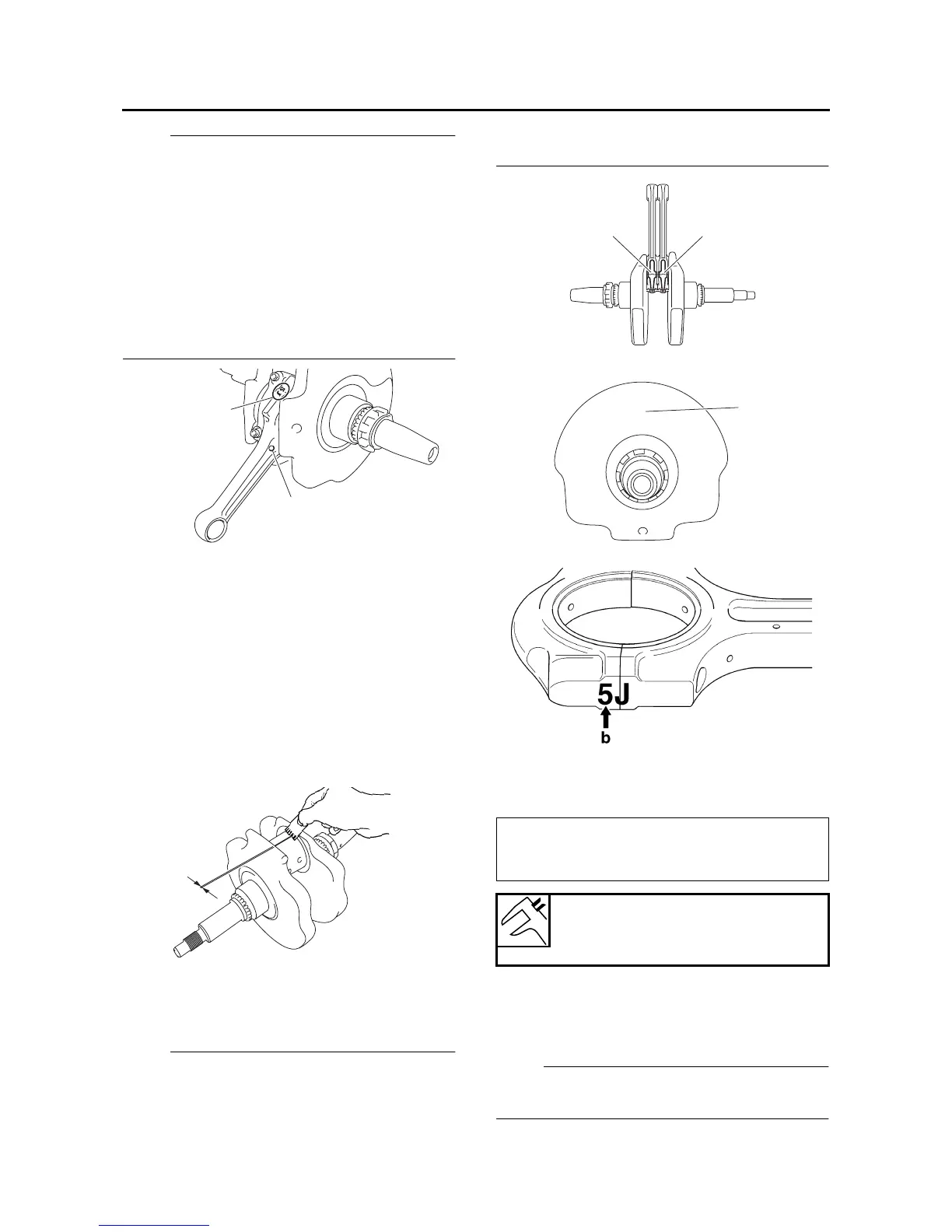

4. Select:

• Big end bearings (P

1

–P

2

)

NOTE:

• The numbers “a” stamped into the crankshaft

web and the numbers “b” on the connecting

rods are used to determine the replacement

big end bearing sizes.

• P

1

–P

2

refer to the bearings shown in the crank-

shaft illustration.

For example, if the connecting rod P

1

and the

crankshaft web P numbers are 5 and 1 re-

spectively, then the bearing size for P

1

is:

5. Measure:

• Crankshaft journal diameter “a”

Out of specification → Replace the crank-

shaft.

NOTE:

Measure the diameter of each crankshaft journal

at two places.

c

d

e

P

1

(connecting rod) - P (crankshaft)

=

5 - 1 = 4 (green)

Bearing color code

1.Blue 2.Black 3.Brown 4.Green

5.Yellow

P1

P2

a

1

Loading...

Loading...